Waste Robotics develops state of the art software solutions for waste material recognition and robotic extraction. The company’s mission is to continue developing state of the art software solutions to recognize waste materials and facilitate robotic extraction. This allows for smaller, more precise, safer, and more profitable facilities for organics, single-stream, and construction and demolition recycling.

Easy Engineering: Why do users choose your products / solutions?

Waste Robotics: We develop tailored solutions to each of our customers, adapted to their needs. We can do retrofit on existing line, so customer don’t need to change his layout.

We have unique technology, as hyperspectral (we’re the only one who use hyperspectral with sorting robots). With hyperspectral, we can see the composition of material and see the difference between plastics. So, we avoid cross-contamination and purity of sorting is much higher.

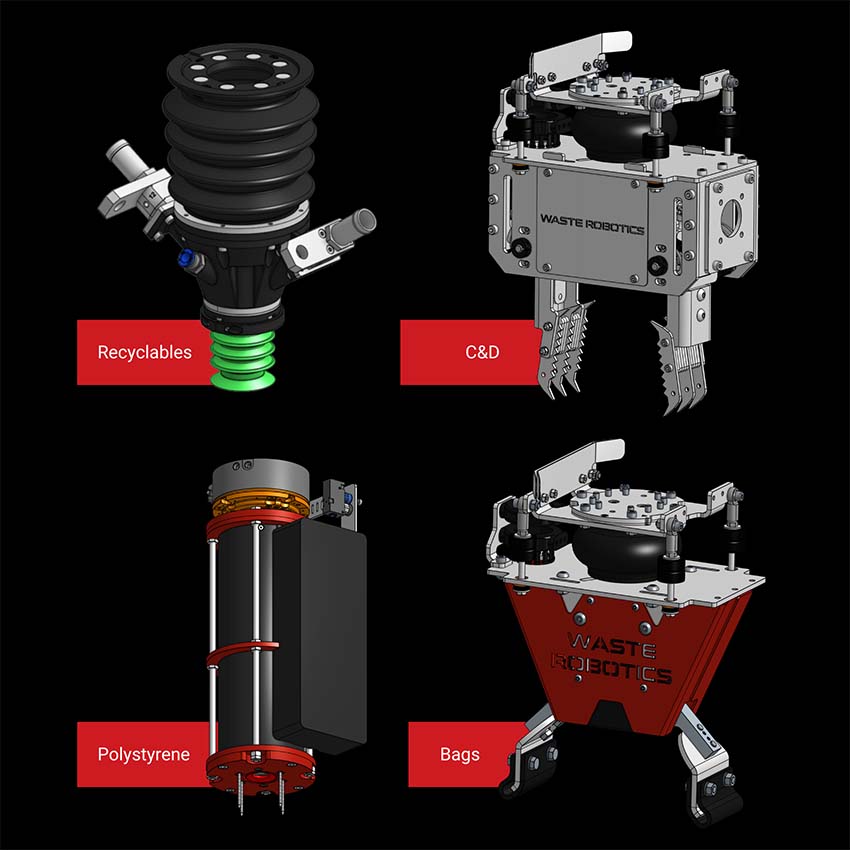

We develop tailored grippers, depending on materials to pick. Each country, city have their own waste, so we adapt our grippers to their specific stream and items to pick.

We are known for our excellent aftersales services.

We use heavy picking robots. They can lift up to 20kg. We’re pretty much the only one in the industry that can do it.

E.E: Give us some examples of projects in which your products / solutions were used.

Waste Robotics:

- Construction/demolition, 3 robots, Cartersville, Georgia (USA).

- We use heavy robots that can lift up to 20kg

- Each robot can sort up to 6 tons/hour

- We use hyperspectral technology to see contaminated materials

With hyperspectral we can also see the difference between wood A, wood B. Which is an important feature. In North America, most of our c&d materials is wood.

E.E: What products / solutions were used in these projects?

Waste Robotics:

- 3 heavy robots

- 1 hyperspectral scanner

E.E: How did your products / solutions improve productivity / efficiency for the users?

Waste Robotics:

- Can process more material

- Can make the robot work 24/7 with a constant speed and productivity

- They can then double their productivity

- Users can track purity of sorting and sell their final product at a better price

Others:

- They no more have to struggle with labor shortage

- Fast ROI

E.E: What was the feedback from users?

Waste Robotics: We have a NPS (net promotor score) of 8.5/10. Customers are satisfied of our customer support/aftersales service

We work with them until their sorting goal is reach

E.E: Which are the most successful products / solutions in your lineup?

Waste Robotics: Our bag sorting is our most mature product with more than 98% efficiency.

Process description:

Our robots are programmed to recognize bags that contain organic wastes, and effectively sort and separate these bags from garbage and single-stream recycling. They sort fast and efficiently (ie. up to nine tons per hour per robot) limited only by how fast you can add more waste to be sorted! The recovered organics can them be sent for composting or for anaerobic digestion and the production of biogas.

Citizens simply place their organic waste in separate, recyclable bags, which they throw in the same bin as other garbage. Bags of organic waste are collected by a single truck with the rest of the garbage – saving money on bins, trucks, and drivers and allowing you to run routes more efficiently. Waste Robotics’ intelligent robot automatically sorts the organic waste bags at the transfer station, in order to recover them for composting or biogas.

E.E: How important is sustainability in your field?

Waste Robotics: Very important. We want to minimize our footprint and act daily to do so.

E.E: What are your forecasts for the rest of 2022?

Waste Robotics: We have many robotic installations to deliver and complete around the globe, especially in Europe and Oceania. We will focus on delivering these projects and to give the best service we can offer.