Manufacturers and engineers in the robotics industry are seeking ways to optimise their manufacturing processes as the robotics sector grows. Laser marking technology is becoming increasingly used to meet the industry’s high-quality and regulatory demands.

If compared to previous marking methods, modern laser marking produces consistently precise results with greater cost-efficiency, dependability, and output quality. Here, we will look at how laser marking technology may be utilised in robotics applications to assure the success of your manufacturing process growth.

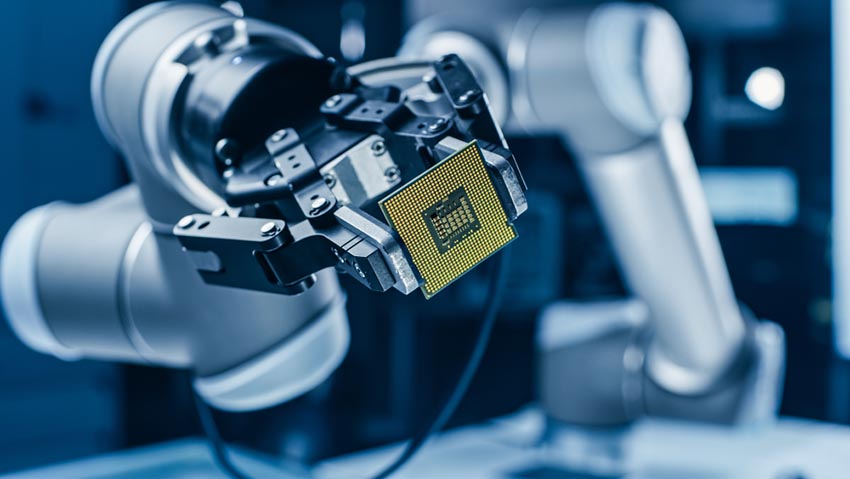

Integrating robotic part marking

Engineers in the manufacturing business are continuously looking for innovative methods to improve the efficiency and cost-effectiveness of their production processes. As robotics become more significant in today’s industrial world, engineers must be aware of the most recent technologies available for coding and labelling robotic units. Thankfully, laser marking technologies have enabled large-scale robot deployment throughout industries globally – and the UK’s laser technology is at the forefront of this boom.

Learning about these modern laser marking systems is critical for engineers searching for a dependable approach to integrating robotic component marking into their operations.

Robotics is rapidly expanding into many industries, but none has experienced as much seamless integration as the manufacturing and production engineering industry. Engineering-related assets are increasingly in demand for laser marking, which might be required for a range of industrial applications that need part manufacture.

It is critical for these firms to accurately and permanently mark assets with exact identification in order to govern and track them throughout their full life cycle. Because of their precision and permanence, laser marking systems are becoming an increasingly popular alternative for identifying components to track their life cycle.

Employing laser technology to mark items has several advantages over older methods like rotary engraving or dot-peen systems. Engineers may use lasers to permanently label a variety of data, including serial codes, matrixes, component numbers, images, and lot coding, all of which can be useful for quality assurance and tracking. Furthermore, laser marking allows for a non-contact, efficient application of a design that does not impair the material’s integrity and allows for the repetition of accurate marking with no disparity between applications.

A further modern need for precise marking is for QR codes; these are used widely for sending a variety of data to anyone who scans one, such as part identification or lifecycle tracking. Depending on the application, a person can discover when a machine or piece of equipment was last serviced by scanning a laser-engraved barcode with a smartphone.

As a result, laser marking is an excellent solution for large-scale manufacturing lines since it allows for rapid and exact identification of items throughout their life cycle. It is also extremely useful in businesses where traceability is critical to ensuring the safe manufacturing and delivery of consumer goods.

Finally, laser marking technology is an excellent tool for engineers seeking precision and traceability in robotic units or other production lines. Laser marking is an excellent alternative for engineers trying to assure quality and lifespan due to its ability to permanently identify items. With fewer moving components, it is a cost-effective technique to raise a production level to whatever scale, efficiency, and quality it aspires for.

Autor: Aled Ellis, Managing Director at Needham Laser Technologies

Aled Ellis is Managing Director at The Needham Group. The Needham Group is the parent company of ink manufacturer and coding printer supplier Needham Ink Tech, industrial laser systems manufacturer Needham Laser Tech, and marking equipment and consumables supplier Needham Technologies IRE.