Interview partner Kai Sievers, CEO of ENDEGS Group.

Easy Engineering: How was 2022 for your business, a short summary?

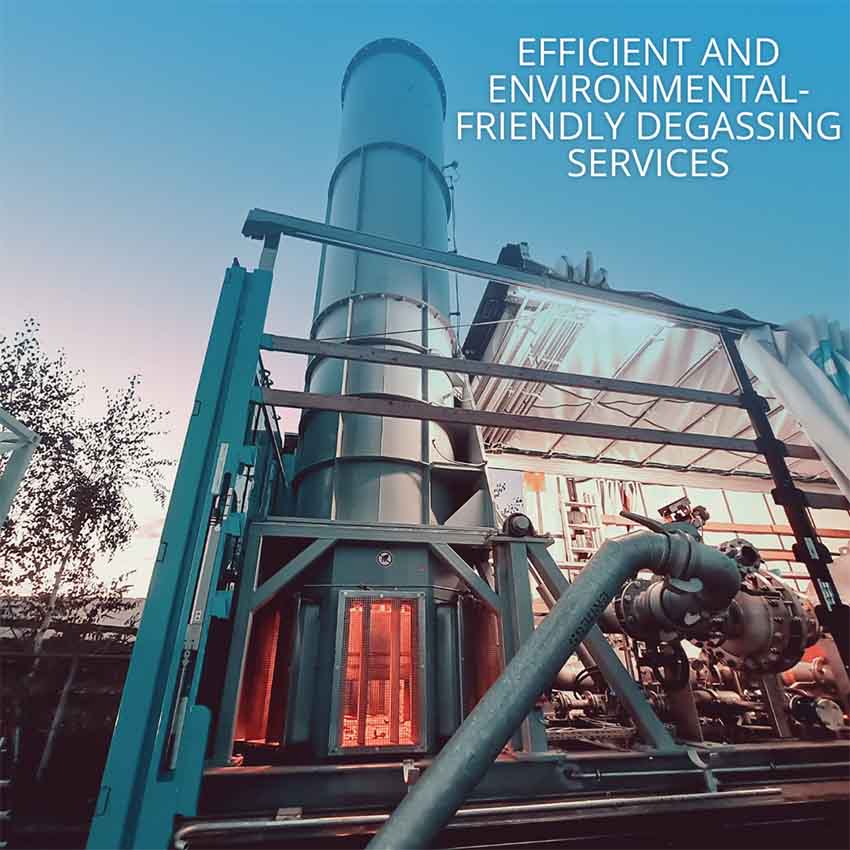

Kai Sievers: In general, 2022 was a good year for us. Our services were well-booked throughout the year and we were able to assist many customers in reducing their industrial emissions. Among those projects were also quite a few major ones. For example, over the summer, we carried out degassing services during a major refinery turnaround in Germany for about two and a half months, degassing about 80 components simultaneously. This was one of the biggest ENDEGS projects to date when it comes to the number of materials we used – we worked with three vapor combustion units and applied a total of 1.9 kilometers of piping.

We also expanded to the Gulf Cooperation Council (GCC) states and attended some of the most important fairs in the region. For example, we presented our company and solutions in Dammam, Riyadh, Dubai and Abu Dhabi. Of course, we also visited European fairs and congresses to strengthen our contacts in the different industries we provide our services for.

E.E: What products/services did you launch this year?

K.S: We always aim to optimize our technologies and improve our portfolio in order to offer our customers as many innovative services as possible. For example, this year, we marketed our new mobile vapor combustion units with a combustion power of 3 MW. This unit is perfectly suited for short-term projects, emergencies and accidents as it is ready for operation directly after arrival. We realize as much combustion performance as possible in a minimum of space with the lowest possible fuel consumption.

We also started to offer the ENDEGS nitrogen services, consisting of a fleet of mobile vaporizers with nitrogen tanks suited to purge and render insert systems and system components handling flaming liquids and gases in all types of pipelines, tanks, barges, bulk containers and many other components. The applications for our nitrogen services are pretty broad: besides for regular deployments and during turnarounds, they can also be used during emergency deployments on a short notice.

E.E: How did the market change, compared to previous years?

K.S: We realize a general trend of a push from society towards industry but also towards authorities. People become more sensitive about personal health and industrial odors, noise, or even visible flames create the uncomfortable feeling of scare – as not everyone is aware of the industry. Society expects improvements from the industry and that they are protected. Thus said, we realize an increase in technical and/or organizational solutions. We are glad to have solutions on this field to support the industry.

E.E: What are the new challenges in your field of activity?

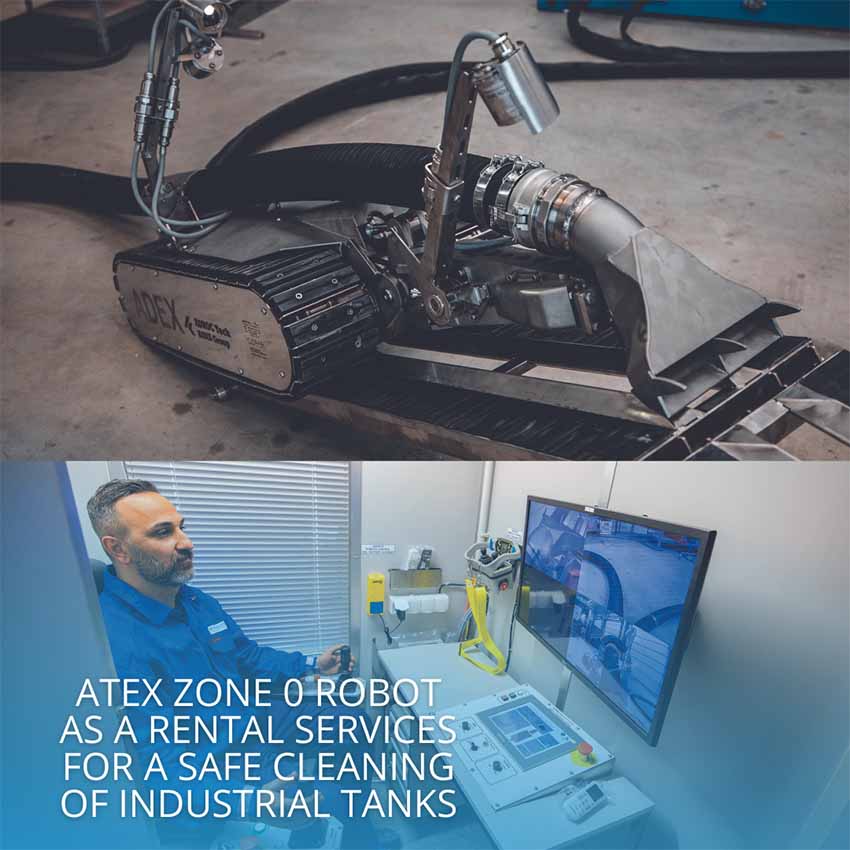

K.S: We always have to adapt to the current requirements of the different industries – in other words, the range of products we work with is forever changing. For example, in the current situation regarding gas supply, LNG is becoming more and more important. As a liquified gas, LNG is highly flammable and therefore hazardous to work with. Other similarly complex products are, among others, butane, ammonia or hydrogen. One of the biggest challenges for us is, therefore, to be able to work with those more complex products as well as the “common” ones. Tank degassing has become standard nowadays and it therefore is important to find solutions for those more difficult challenges.

E.E: How did you overcome these challenges in this more competitive environment?

K.S: For us, the most important thing is to carefully listen to our clients and try to understand their business needs. Secondly, we are a family-owned business – entrepreneurs – and we are never standing still and constantly developing ourselves and our technologies. With our well-trained staff, efficient processes and flexible patented combustion units, we are a partner that can offer solutions for just these challenges.

Let’s come back to the example of working with liquified gases. They have a high risk of ignition and explosion. Just recently, we were part of a major emergency project in Germany involving such a liquified gas and an acute risk of explosion: two trains collided and one of those contained propane. Four railcars with the highly flammable gas derailed and the risks of inflaming, the ignition of the propane and subsequently an explosion were very acute. To end this hazardous situation, we inerted the damaged railcars with nitrogen to flush the propane out and guide it safely to the flare where it could be burned off.

We have already faced many a difficult challenge since 2008 – thanks to our motivated team and the long and reliable relationships with our partners, we have yet mastered every one!

E.E: Tell us about product innovation and how will it impact the future?

K.S: When we developed our first mobile vapor combustion unit to degas all types of VOC (volatile organic compounds) and HAP (hazardous air pollutants) emissions back in 2008, that was an innovation in itself: for the very first time, we made mobile emissions treatment possible world-wide. ENDEGS is the only company in Europe operating mobile incinerators that burn all kinds of gases, gas mixtures and vapors of the explosion groups IIA, IIB and IIC with a combustion rate of over 99.99 % and no open flame.

Having said that, product innovation is a very, very important topic for us. For the second year in a row, we have been named one of the 100 most innovative medium-sized companies in Germany in 2022. Innovation and expanding our portfolio of technologies and services allows us to work with more complex products. Now, even difficult products such as hydrogen, ammonia, propane or butane can be treated safely and efficiently by us. To achieve this, we use the experience from our successfully realized projects and adapt them to the current market conditions.

E.E: How will product innovation help the customers?

K.S: Every service we offer has one aim: delivering a worry-free and efficient package to our clients, including technology, know-how and support. After all, we want to ensure that we increase the efficiency of our services. When it comes to product innovation, we always pay close attention to our customers and their needs and demands, too. Do they, for example, work with another product that our services are not suitable for? Then of course we do everything to find a solution and to extend our technologies for that specific product. Many of our innovative ideas therefore emerge from our daily work “in the field”. Due to the effectiveness of our services, we can reduce downtimes of the facilities we work in to a necessary minimum – daily operations can continue undisturbed or with only minimal interference. This saves our customers time and money as their business can keep going almost as usual during our work process. By constant research and developing our technologies and services, we extend the applications of our technologies so that more and more industries can apply our service – and benefit from noticeably reducing their emissions.

E.E: What are the industry trends in the markets you are currently active?

K.S: Climate neutrality and the health and safety of employees are becoming increasingly important in the industries we work in. The protection of the surrounding neighborhoods around the industrial areas is equally important. By 2050, Europe but also the industrial majors promised and challenged themselves to become climate-neutral – no more greenhouse gases are to be released in the atmosphere that are not otherwise compensated. To achieve these goals, new “energies” like hydrogen, ammonia (green) as well as improvements in efficiency of plants will be implemented as well as new global supply chains. Our solutions for reducing industrial emissions protect the society, improve supply chains by guaranteeing to be legally compliant and are perfect for contributing to this goal.

Kai Sievers, CEO of ENDEGS Group

E.E: What do you think the trends will be next year?

K.S: From top level view, we will see a lot of new “green” projects – for example the implementation of production facilities for green ammonia and LNG terminals – coming along with the implementation of new supply chains around the globe. The manufacturers of the new facilities (sender) but also the clients (receiving countries) need to build infrastructure based on best available technology. On regional and country level down to individual companies, we expect further improvements in their current infrastructure and processes to achieve environmental goals.

E.E: What is the outlook for 2023?

K.S: We on the one hand see an increase in the demand of our services and are more than happy about this evolution. On the other hand, we see challenging times in the sense that our clients need more and more consulting in their individual needs. In this “new times” we see a run on everything that looks “green” – but it is important to figure out what is the best tool, technical upgrade or change in the working process to be legally compliant but also achieving environmental goals. That needs a lot of trust and operational knowledge to consult and guide clients the right way – and not simply selling something.