Prime Vision is a global leader in computer vision integration and robotics for logistics and fulfillment. Focussed on vision and decision systems and supported by strong capabilities, the company applies best-in-class technologies using machine vision, recognition and identification, AI and deep learning and are able to integrate their solutions seamlessly and secure in customer’s operation.

Interview with Hans Jongebloed, Senior Postal & Parcel Expert at Prime Vision.

Easy Engineering: How was 2023 for your business, a short summary?

Hans Jongebloed: Prime Vision stands as an AI-powered leader in postal/parcel logistics and Fulfilment services. With a legacy spanning over two decades, we pioneered cutting-edge Computer Vision solutions for address reading in both handwritten and machine-printed letters and parcels. Presently, our suite encompasses AI-driven products spanning Computer Vision, Sorting Intelligence, and Robotics.

While the crux of our solutions remains software-based, our robotic technology represents a pinnacle of our hardware engineering endeavours. With a fleet of more than 750 deployed robots, our focus in 2023 was on elevating the capabilities of these robots significantly. We achieved a remarkable expansion, augmenting their functionalities by over 200% in terms of increased exits and parcels processed per hour. This milestone underscores our commitment to pushing the boundaries of robotic efficiency and performance.

E.E: What products/services did you launch this year?

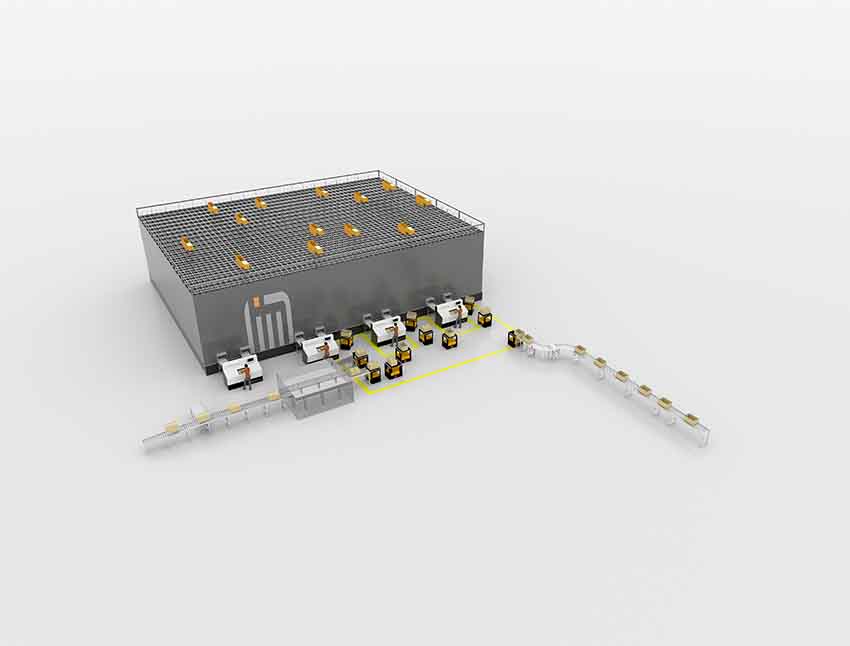

H.J: Building upon the capabilities of Autonomous Mobile Robots (AMRs) capable of handling diverse sorting processes, we introduced a pioneering concept leveraging robots to streamline order fulfillment from Automated Storage/Retrieval Solutions, such as Autostore and Intellistore. Our innovative approach involves robots gathering picked orders, managing tasks like erecting boxes, transporting them to packaging stations for sealing and labeling, and ultimately, sorting them accurately for shipment to designated destinations—be it carriers or proprietary stores/channels.

In 2023, we successfully executed multiple projects in this domain, including two significant ones in the Netherlands, our base of operations.

Notably, our breakthrough also demonstrated the adaptability of our robots in handling larger items that traditionally necessitated manual sorting due to their size, surpassing the constraints of contemporary parcel sorting machinery.

E.E: How did the market change, compared to previous years?

H.J: The e-commerce market experienced rapid expansion during the Covid-19 lockdowns, prompting various operational hurdles. These challenges included the establishment of pop-up sorting locations, where our robots played a crucial role in facilitating sorting processes. However, in 2023, there has been a shift towards a more normalized scenario. The explosive growth seen during the pandemic has tapered off, signalling a return to pre-pandemic conditions, albeit with sustained higher volumes compared to before. In light of this, our customers are reassessing their growth strategies, recognizing that while the guarantee of continuous exponential growth has diminished, they still anticipate increased volumes in the future.

E.E: What are the new challenges in your field of activity?

H.J: The surge in e-commerce has introduced unprecedented uncertainty in predicting growth patterns. As a result, there’s been a significant slowdown in investments within sorting systems, and a re-evaluation of warehouse automation strategies. Notably, even industry giants like Amazon have halted multiple large-scale warehouse automation projects, causing cancellations in orders for material handling system vendors.

E.E: How did you overcome these challenges in this more competitive environment?

H.J: The adaptability and agility of our robotic solution prove invaluable in times of uncertain growth. With our system, you have the flexibility to commence operations with a smaller fleet of robots. This allows you to defer investments in future expansion until your growth trajectory stabilizes. Unlike conventional ASRS (Automated Storage and Retrieval Systems) setups that are often purchased with future growth in mind, our robotic solution offers a scalable approach. It begins with a more modest throughput capacity, easily extendable as your needs evolve and your operations expand.

E.E: Tell us about product innovation and how will it impact the future?

H.J: Our product innovation revolves around enhancing the throughput capacity of a fleet of robots by optimizing their route planning. This ensures minimal interference among robots, thereby avoiding delays. This breakthrough allows us to achieve throughput levels typically associated with large sorting machines equipped with substantial fixed installations. Unlike these traditional setups, our adaptable robots offer unparalleled flexibility. They can seamlessly operate in a single facility for several years and then swiftly transition to a new location within a few weeks. Moreover, our fleet can be easily distributed across multiple sites, catering to capacity needs wherever necessary.

E.E: How will product innovation help the customers?

H.J: Our innovations cater to customers navigating uncertain growth trajectories by offering solutions that scale alongside their evolving needs. This approach contrasts starkly with investing in systems that might possess capacities far beyond immediate requirements, possibly only becoming relevant in a future business landscape that has significantly evolved.

Conventional sorting machines and Material Handling systems often boast a technical lifespan exceeding 25 years, a substantial duration by any measure. Reflecting on the pace of change, consider that merely 25 years ago, e-commerce was in its infancy—a novelty. The meteoric rise of e-commerce since then serves as a testament to how swiftly business landscapes can transform.

Our commitment lies in providing adaptable solutions that dynamically grow with our customers, sparing them from overcommitting to capacities meant for a distant future, while ensuring they remain agile and equipped for the evolving demands of tomorrow.

E.E: What are the industry trends in the markets you are currently active?

H.J: The processes of sorting parcels and picking/packing products in e-commerce warehouses remain heavily reliant on manual labour. However, the challenge lies in the increasingly difficult task of sourcing personnel to fulfil these roles. As the e-commerce sector continues its upward trajectory, the imperative for increased automation becomes ever more pronounced. Simultaneously, the scarcity and escalating costs of suitable locations for new warehouses and sorting centres pose considerable challenges.

Consequently, there’s a rising trend where existing facilities are leased for shorter durations, typically a few years, emphasizing the growing need for flexibility in operations. This necessity stems from the evolving landscape, compelling businesses to adapt swiftly and leverage existing spaces while addressing the constraints of finding and establishing new facilities.

E.E: What do you think the trends will be next year?

H.J: In the e-commerce and retail sectors, numerous warehouses are poised to embrace automation. This strategic shift aims to reduce dependence on scarce labour resources while offering an initial capacity that can seamlessly expand in the future. By investing in automation, these facilities anticipate a more sustainable operational model that mitigates reliance on hard-to-find personnel while laying a foundation for scalable growth.

E.E: What is the outlook for 2024?

H.J: Prime Vision remains at the forefront, selling our robots to various sectors, including bulky parcel sorting operations and in collaboration with warehouse automated picking solutions. Our robots play a pivotal role in enhancing efficiency across diverse industries, catering to both large-scale parcel sorting requirements and seamlessly integrating with cutting-edge automated picking solutions within warehouse environments.