In today’s reality, automation plays a big part in terms of food safety, product consistency, dealing with labor shortage, and better utilizing valuable employees to more beneficial work assignment. However, the implementation of automation often involves various challenge such as space constraint, equipment adaptability, as well as technologies limitation which makes it incredibly difficult to identify the proper equipment that can handle your own product characteristics and overall operational requirements. To cope with this new reality as well as its associated challenges, Lizotte Machine Vision manufacture inline system combining x-ray and vision technology.

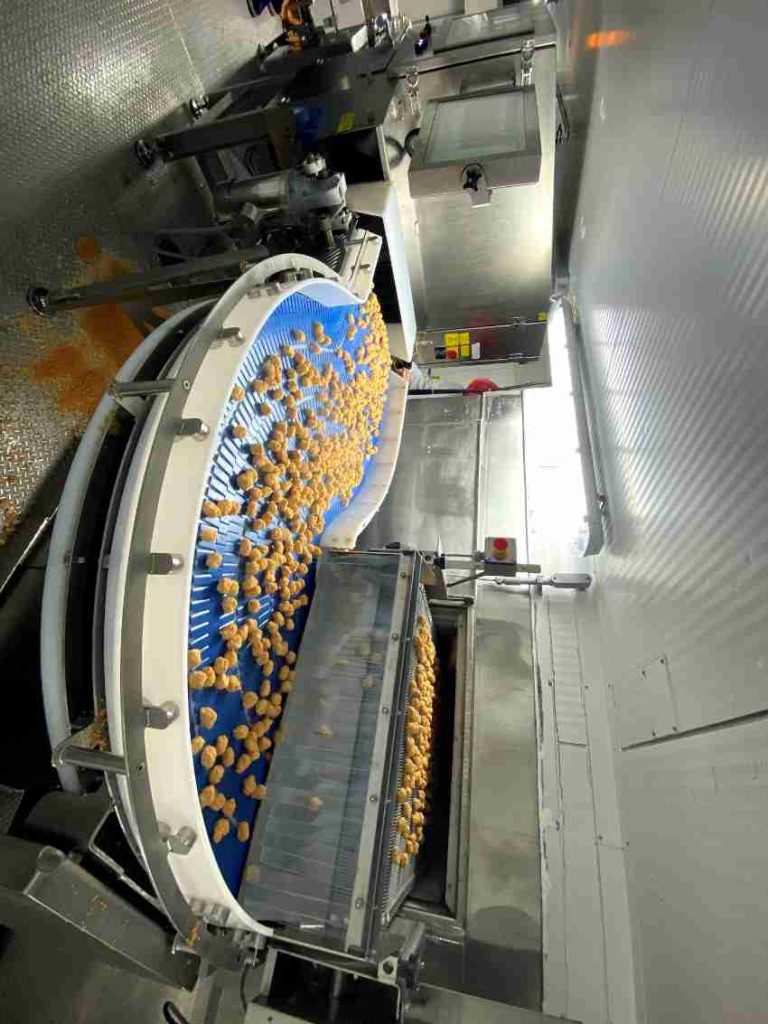

Using color camera, laser, and/or x-ray technologies LMV manufacture custom-built systems designed according to individual inspection and/or grading requirement, space limitation along with adapting unique ejection mechanism to each product. Consequently, LMV has developed a wide range of systems for large food manufacturing companies to fulfill specific needs in the poultry, meat, seafood, bakery, vegetable, and canning industry. Depending on the application, the system will inspect product in real time and sort out non-compliant product from the processing line and/or it will grade each individual piece into its appropriate category based on size, shape, color, and/or weight attribute. This high level of machine adaptability gives the process plant a wide range of flexibility within their process.

LMV most innovative aspect is the fact that we combine x-ray and vision technology within the same machine. By combining both, the system can detect anything from a shape defect to low-density foreign material, to bones, breading voids, blood spot, weight discrepancies and much more. On top of that, our system can work in various stage of processing such as fresh, after former/slicer, after oven/fryer and after IQF. Here are a couple of example fo x-ray and vision combination system:

- Post Fryer Inspection: https://www.lizottemachinevision.com/product/post-fryer-sorter/

- Post Former Inspection: https://www.lizottemachinevision.com/product/post-former-sorter/

- Poultry Inspection: https://www.lizottemachinevision.com/product/breast-sorter/

Each system uses a custom designed rejection conveyor which isn’t affected by the orientation of the product on the belt. The product can be randomly fed to the line in a single layer and the system will automatically eject the defects without rejecting good product. Along with rejecting the defects, the systems can include a deviation gate which will separate the geometry defects from the contaminated products. Our customer can rework the meat that as been rejected for geometry defects and that will reduce their waste and increase their heal.

Keeping in mind the labor shortage and the importance of food safety, custom system like LMV’s help reducing the number of employees doing repetitive task along with increasing inspection capabilities. Using our technology help having a constant inspection and grading all day long. The systems have presets parameter files that will be programmed for each different products that are manufactured on that specific production line.

Finally, LMV is focused on engineering systems that helps improving your product quality and reduce the labor costs. Along with the fact that each system is tailor made, we make sure that each system is build taking in consideration your space requirements, plant design and recommendations. Contact us to design your own system.

Mathieu Bosse – Business Development Director

Bossem@lizottemachinevision.com

1 (506) 740-6337