3D Formtech is a company specialized in 3D printing. The company was founded in 2014 and it is located to Jyväskylä in the middle of Finland. The main focus is providing high quality industrial parts in small or medium size series. To get the most out of AM manufacturing SLS and DMLS has been selected as the printing techniques. In addition, they offer wide selection of materials (polymers and metals), design consultation, quality management, latest post-processing systems and 3D-scanning guarantee that a wide range of series production can be carried out at the required level.

Currently the number of staff is under 20 and turnover is about two million. Annual growth has been around 20% and 3D Formtech has achieved benchmarking position in Finland and our growth continues. 3D Formtech is using the latest EOS polymer and metal printers.

Easy Engineering: What are the main areas of activity of the company?

3D Formtech: SLS and DMLS small or medium size series manufacturing with 11 different materials. The biggest client segment is industrial companies. The most of our customers are located in Europe.

E.E: What`s the news about new products?

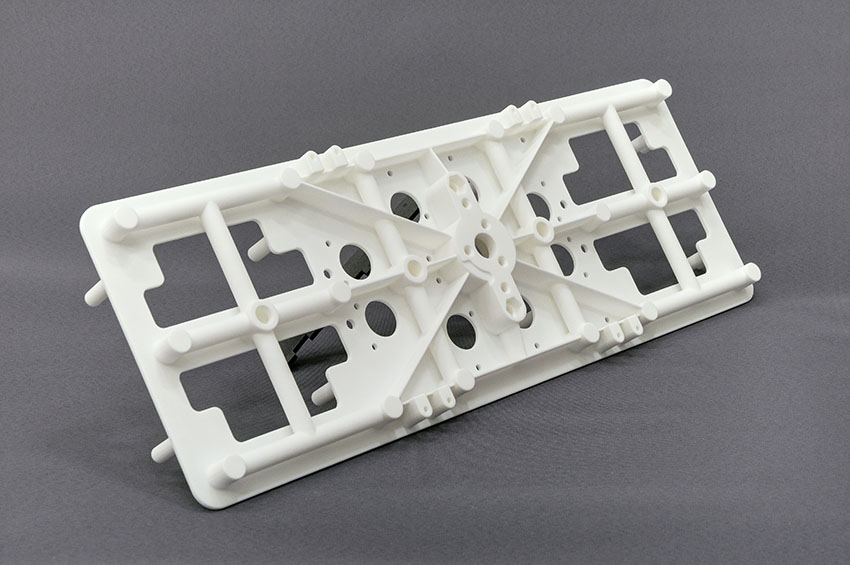

3D Formtech: Nowadays more and more 3D-printed parts are utilized for the additive manufacturing. Designs are not anymore familiar to traditional way produced. Products contains topologically designed structures, combined assemblies, ready-made mechanisms and many other functions. A fundamental change in product design has clearly taken place. The question is not anymore how to manufacture product but what is intent that product need to do.

E.E: What are the ranges of products?

3D Formtech: The range of our products is wide. From aviation to medical industry. From motorsport to free time. All industries and art included.

E.E: At what stage is the market where you are currently active?

3D Formtech: Globally AM overturn has risen 20% annually speed. Corona pandemic has had of course braking affect, but it has been only temporary. Actually, pandemic has shown also benefits of AM manufacturing especially cases when rapid actions and implementations have played a key role.

E.E: What can you tell us about market trends?

3D Formtech: Green values, modified supply chains, customized products, 4D-printing (intelligent materials and structures), digital spare parts are some of trends what we can see from our point of view. We also strive to respond to these trends to the best of our ability.

E.E: What are the most innovative products marketed?

3D Formtech: We have couple of products with images which could be added here.

E.E: What estimates do you have for 2022?

3D Formtech: Our estimation for 2022 is that the amount and size of series will grow even bigger. The confidence of our clients related in the quality of 3D prints is growing and pricing is more efficient than ever. Breakeven between casting series and printing series has been pushed further and further which raises the threshold for the acquisition of molds. The business of metal printing is likely to grow relatively even more in 2022. In addition, the number of post-processing systems will expand. Couple of totally new processes are in implementation progress and others are in investigation.