As a specialist in the distribution of 3d printers, 3d scanners and 3d software, 3D-MODEL supports customers in Germany and Switzerland in the optimization of their production processes. The company advises them from data acquisition through to the end-use part. Both SMEs and large companies receive through the integrating of their innovative technologies, from development to manufacturing of the functional component an enormous increase in efficiency.

Interview with Philipp Binkert, Company position: CEO & Founder of 3D-Model.

Easy Engineering: What are the main areas of activity of the company?

Philipp Binkert: The distribution of 3d printers, 3d scanners and 3d software as well as related services in additive manufacturing and 3d-scanning. Our certified service technicians and CAD specialists take over the inspection, maintenance and repair of the 3d printers and 3D scanners for our customers at any time. This means that they are well looked after from the start of the business relationship.

E.E: What’s the news about new products?

P.B: We have a new Formlabs SLS 3d printer in our product portfolio since last year. It features low initial cost, affordable materials and efficient recycling of nylon materials with its compact, reliable system.

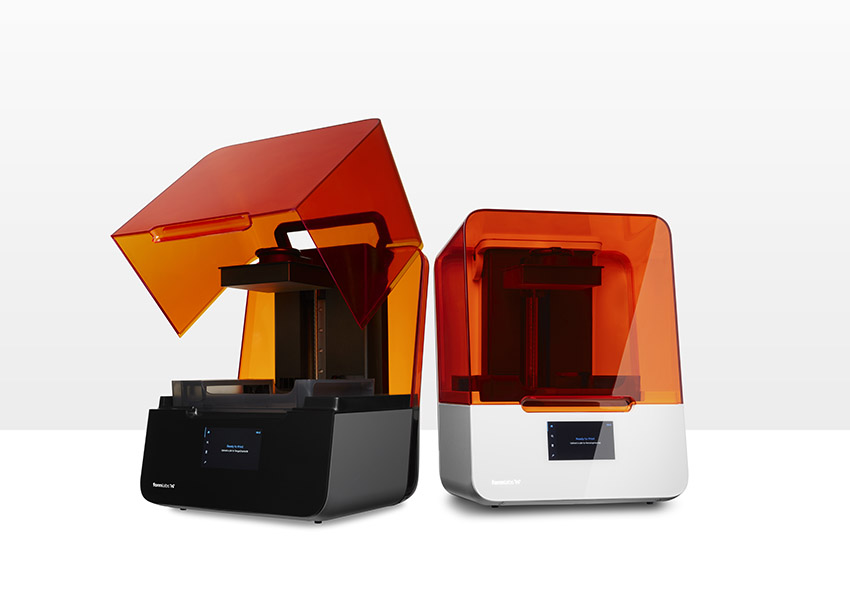

We also offer the latest innovations from our manufacturer Formlabs, the new Formlabs Form 3+ and Form 3B+ 3d printers, which are characterized by improved hardware and software. There is also the new Build Platform 2 for the Formlabs 3D printers just described. This platform is characterized by its quick release technology and reduces the postprocessing time enormously. Also, the new advanced Markforged FX20 3D printer is on the market. With this, parts of the highest quality can now be manufactured even faster and in larger formats.

E.E: What are the ranges of products?

P.B: We work with the manufacturers Markforged, Formlabs and 3DCERAM in the field of 3D printing. In the 3d scan area, we offer 3d scanners from Artec 3D. The software area contains softwares from 3D Systems, Artec 3D, Formlabs and Markforged. Depending on the 3D printer, metal, plastic and ceramic materials can be processed. With the Markforged 3d printers the components can be reinforced with continuous fibers.

Our Formlabs 3d printers work with both SLA and SLS technology. The SLA product range includes the Form 3+, Form 3L, Form 3B+ and Form 3BL 3d printers. Different synthetic resins can be printed. The 3d printer Fuse 1 works with the SLS technology. There are currently two materials here: Nylon 11 and Nylon 12.

The CFR process is used in the Markforged 3D printers. We offer the Markforged metal printer Metal X and the composite fiber 3D printer FX20, X7, X5, X3, Mark Two, Onyx One and Onyx Pro.

The 3DCERAM 3d printers work with the SLA technology and offer a wide range of ceramic materials. There are the following 3d printers: C100 Easy FAB, C100 Easy LAB, C900 FLEX, C900 HYBRID and C3600 ULTIMATE.

There is also a breathtaking variety of 3D scanners from Artec 3D: handheld scanners, desktop scanners and long-distance scanners. Their Names are: Artec Eva, Artec Eva Lite, Artec Leo, Artec Space Spider, Artec Micro and Artec Ray.

E.E: At what stage is the market where you are currently active?

P.B: The 3d printing market is constantly growing and still has great growth potential. The acceptance and trust in the technology is increasing among companies.

E.E: What can you tell us about market trends?

P.B: Currently, the trend is very strongly towards in-house production. The corona pandemic has forced companies to think about in-house production. Here 3d printing plays a major role because it can be integrated into in-house production at low costs and also brings time and cost advantages within production.

Companies can benefit enormously from 3D printing, especially in the manufacture of tools and devices, in the injection molding area for the manufacture of molds and in the development department. Prototypes can be produced much faster and adjustments can be implemented more quickly. Of course, 3d printing is also great for manufacturing end-use parts.

3d scanners are still an important part of data acquisition and will remain so in the future. For example, 3d scanners are used for data collection when there is a need for spare parts that are no longer available on the market, in healthcare for the manufacture of implants, as well as in creative fields such as art etc.

E.E: What are the most innovative products marketed?

P.B: Currently our most innovative products are the Formlabs Fuse 1 SLS 3d printer and the Markforged FX20 composite fiber 3dprinter. Our 3DCERAM 3D printers are very appealing due to their range of ceramic materials as the ceramics market continues to grow. 3d scanners can be used in all industries. Artec 3d scanners are always state-of-the-art.

E.E: What estimations do you have for 2022?

P.B: Our estimation is that in-house production with 3Dprinting will continue to gain traction in the future as companies have now seen the benefits of additive manufacturing first-hand through the pandemic. In addition to avoiding delivery bottlenecks, this brings many other advantages, such as cost and time reduction, easy handling, enormous speed and flexibility it the manufacture of components and many more.

3D-MODEL