Accurl CNC machine (Anhui) manufacturer is specialize in industrial manufacturing for 30 years. In the beginning the company was doing accessories of machines for China domestic market, as the time goes on and with the rapid development of technology, they start to design and produce their own machine since 2008. Accurl brand export to more than 190 countries and regions. The main products are: CNC press brake / Hydrauilc guillotine / Fiber laser cutting machine / CNC turret punching machine and so on. The company’s target is offering the One-stop service for the customer.

Easy Engineering: What are the main areas of activity of the company?

ACCURL: We mainly focus on the research and develop of new products. Continuously improve for the customer usage and convenience. According the customer’s different kinds of workpiece, Our CNC press brake be designed the multifunction stop finger, cooperate with Delem to design our own HMI control interface. Smarter, higher energy efficient. Now we are advancing with The Times, devote our self to AI and Industrial 4.0 technology.

E.E: What’s the news for 2020 about new products?

ACCURL: Our hydraulic press brake update to Hybird press brake and full electric servo press brake, we promote a friendly environmental policy, and, such as, all our equipment features the Hybrid Eco Function.

This hybrid servo-drive system positioning accuracy at target position. Depending on cycle characteristics and rating, servo pump drives achieve energy savings.

Full electric servo machine, with the accuracy which has the ability to program the punch finger to plus or minus .001 degrees bending angle. There is another advantage to the all-electric press brake driven by servo motor, the machine never warms up. No heat is transferred to the rest of the machine as hydraulic press brakes tend to do. The ACCURL ICON Series, all electric press brake, retains first part accuracy for the entire time the machine is producing parts, no readjustment necessary. Another advantage is the operating sound volume. The ICON’s sound output compared to a hydraulic machine is like comparing people whispering in a library to fans screaming in the stands for their favorite sports team.

We also cooperated with Delem and Lasersafe to research and develop Lasersafe IRIS PLUS Series use for Delem control and use its laser check angle function, Bend Vision technology provides a range of real-time angle measurement data that includes the inside and outside angles of the material, average angle, material warp angle, material spring back angle for various material types, thickness and grain direction, plus end of relaxation angle once the bend has been completed.

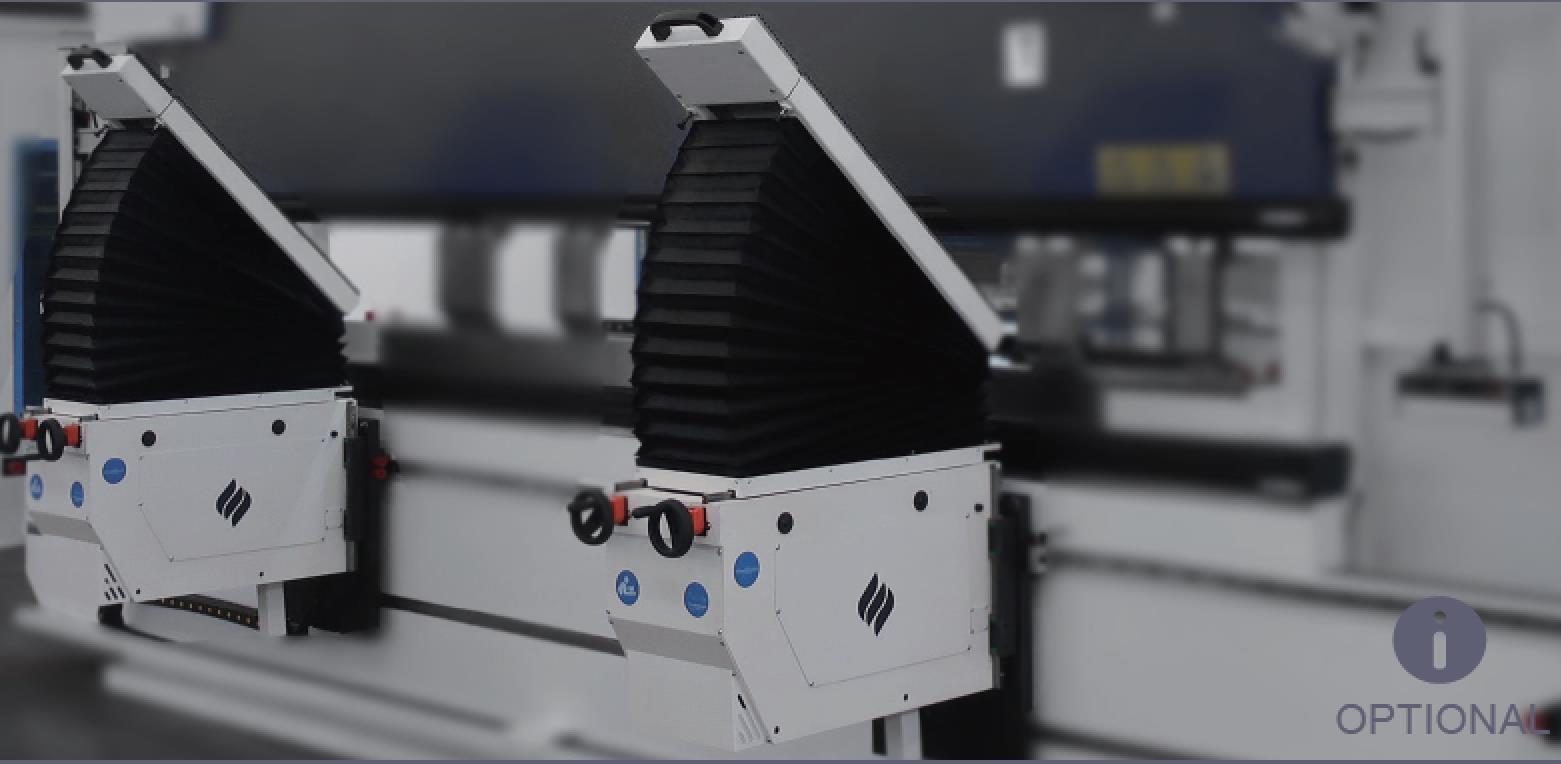

On the other hand, we adopted front servo follow support and we have greatly reduced the customer’s workload for thick plate processing. Basically, it consists of a pair of sheet supports placed on the front of the machine at the height of the bending line (bottom tool). Supports are controlled by the CNC, following and supporting the sheet during the bending process.

E.E: What are the ranges of traded products?

ACCURL: CNC press brake / Hydrauilc guillotine/Fiber laser cutting machine/CNC turret punching machine and so on.

E.E: At what stage is the market where you are currently active?

ACCURL: USA and Europe. These two markets are been stable. Currently active markets are Vietnam, Bangladesh, India and some middle eastern countries. They are developing infrastructure and industry and have great demand for our corresponding products.

E.E: What can you tell us about market trends?

ACCURL: At the moment, the global economy is paused because of the impact of the corona virus, but China is the first country to contain the coronavirus, so we think that after the recovery of the world, the productivity of other countries will be weaken in a short time, so products made in China will be explosive growth for the world products demands.

E.E: What are the most innovative products marketed?

ACCURL: ACCURL represents a synthesis between technological innovation, & attention to detail/design. Add the best components in the world, and Accurl offers customers the foremost solution with an impressive Quality & Price ratio. The new Hybrid Servo CNC Press Brake combine power and precision into a Europe design. Using a combination of electric and servo drive systems, these hybrid machines are highly efficient, impressively quiet and utilize the latest in Accurl Motion Technologies and the Premium is the ultimate in creating complex parts. We devotion to continuous product innovation results in your ability to achieve high performance, with reduced production costs and scrap. These superbly finished machines are fast in their axe movements, and are one of the most productive hybrid servo CNC press brakes on this planet. ACCURL simply delivers precise, reliable, & cost-effective solutions to best fit your needs.

Due to the increasing demand worldwide to decrease our carbon foot print, and become as efficient as possible, ACCURL has developed a new series of Green Electric press brakes, the eB ICON (Eco Bend) all Electric Press Brake Series. With the addition of these state of the art all electric press brakes for manufacturing, Accurl USA will be firmly ensconced in the upper echelon of precision press brake manufacturers worldwide. The new technology of all electric press brakes was created with one major goal in mind. The goal was to produce an all servo electric press brake which would reduce consumption of fossil fuels by at least 50% or more. Currently we are able to offer these highly sophisticated Eco-friendly servo electric press brakes in multiple sizes & configurations to pair perfectly with any production environment.

E.E: What estimations do you have for 2020?

ACCURL: In the first half of the year, the coronavirus led to the global economic downturn, and many enterprises closed down. It is expected that there will be a turning point in the second half of the year, when the global economy recovers it will fully enter the high-tech era. After the outbreak, the companies that remained were resilient to pressure and frustration. They will get more accelerate research and development of their product.