Adfil stands for over three decades of experience in the development and application of synthetic fibre concrete reinforcement. The company serves the construction industry in over 70 countries and Adfil’s high performance fibres are used in a wide range of applications. Examples include industrial concrete floors, pattern imprinted concrete, precast concrete products and tunnelling.

Easy Engineering: What are the main areas of activity of the company.

ADFIL: Adfil is a manufacturer of synthetic micro and macro fibres and all our products are put on the market after long R&D development and testing. We have our own R&D lab at the factory, work very closely with universities and engineering companies and we continuously improve our products. In a nutshell, Adfil is equally active on manufacturing, development and challenging status quo.

E.E: What’s the news about new products?

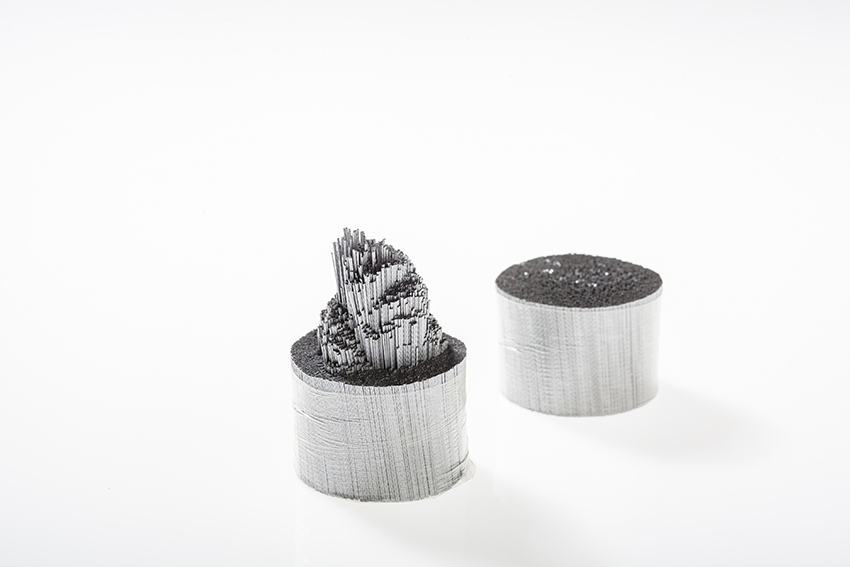

ADFIL: When developing new products we take it step by step. Our first challenge was passive fire protection in precast elements. We performed many tests to figure out which fibre parameters influence the reduction of explosive spalling of the concrete in the tunnels & high rise buildings. We developed the best performing fibre and this is how Ignis was born. Then Durus EasyFinish, our macro fibre star product in the market has been developed after many years of research. The first version Durus macro fibres was dosed at 12kg/m³, where currently we are at CE dosage of 2,5 kg/m³. The most recent development was Durus EasyShot for shotcrete, where Adfil obtains the highest performing in the market over and over again. We are already supplying to some f the famous tunnels around the world.

E.E: What are the ranges of products?

ADFIL: Currently we have 2 product lines in the range: micro fibres & macro fibres.

E.E: At what stage is the market where you are currently active?

ADFIL: We are far from a mature market & see great opportunities to develop the market from a knowledge & product point of view.

E.E: What can you tell us about market trends?

ADFIL: With the current global economic situation, everything become more expensive. The construction sector needs cheaper material and higher labor efficiency. Fibres in this case thicks all the boxes & significantly helps the sector to build at lower cost and improve ease (no steel fixing labor needed) & speed of installation (no steel fixing time). Although the products have proven themselves time after time without failure, construction and engineering companies are still using traditional steel reinforcement because this is what they are used to. Now, these companies understand there are more sustainable solutions than steel reinforcement. We receive more and more questions from around the world to convert their steel reinforcement designs to fibre reinforced designs. This trend is a definitive win.

E.E: What makes Adfil different from the other manufacturers?

ADFIL: We are aware there are serious contractors and engineers out there looking for professional solutions to replace steel reinforcement. Adfil works with two engineering offices to calculate fibre reinforced concrete designs. We offer this service to all our customers with PI insurance and make different designs from slabs to foundations, to walls and any sort of tunnels. We design high quality and long lasting structures that comply with European Norms and respect CE dosage. We also developed software for our preferred partners to make their own designs within minutes.

E.E: What are the most innovative products marketed?

ADFIL: Our products of course. We keep on developing to become more user friendly and increase performance.

E.E: What estimations do you have for the 2022?

ADFIL: A construction market which finds some equilibrium to start 2023 with a healthy supply & demand, allowing us to concentrate on sustainability building a bright future for the construction industry.

More info at: