AFA Systems was founded in 2001 by Paul HJ Langen (here within Paul). Paul was the former Owner and President of Langen Packaging, which is now known as Mpac Langen. AFA Systems operates out of a 30,000 sqft facility in Brampton, ON, Canada. They specialize in manufacturing fully automated packaging machinery lines. The company’s product range includes cartoners, case packers, tray packers, case erectors, and palletizers.

The company’s goal is to provide equipment that meets the end user’s specific packaging requirements. AFA Systems designs their equipment for the customer’s package and not the other way around. This strategy allows their customers to fulfill their packaging marketing requirements and enables our company to provide innovative solutions. The company’s packaging machinery can be seen across the world in countries such as China, South Korea, Australia, Chile, Brazil, Argentina, Mexico, and Indonesia.

Easy Engineering: What are the main areas of activity of the company?

AFA SYSTEMS: Our main areas of activity are in the household consumables, pharmaceutical, and food & beverage industries. Since we offer flexible machinery, our machinery is designed to meet each industry’s specific requirements.

E.E: What’s the news for 2021 about new products?

AFA SYSTEMS: We have designed a new high speed cartoner that handles vials of product at 1,200 vials per minute.

Details are below:

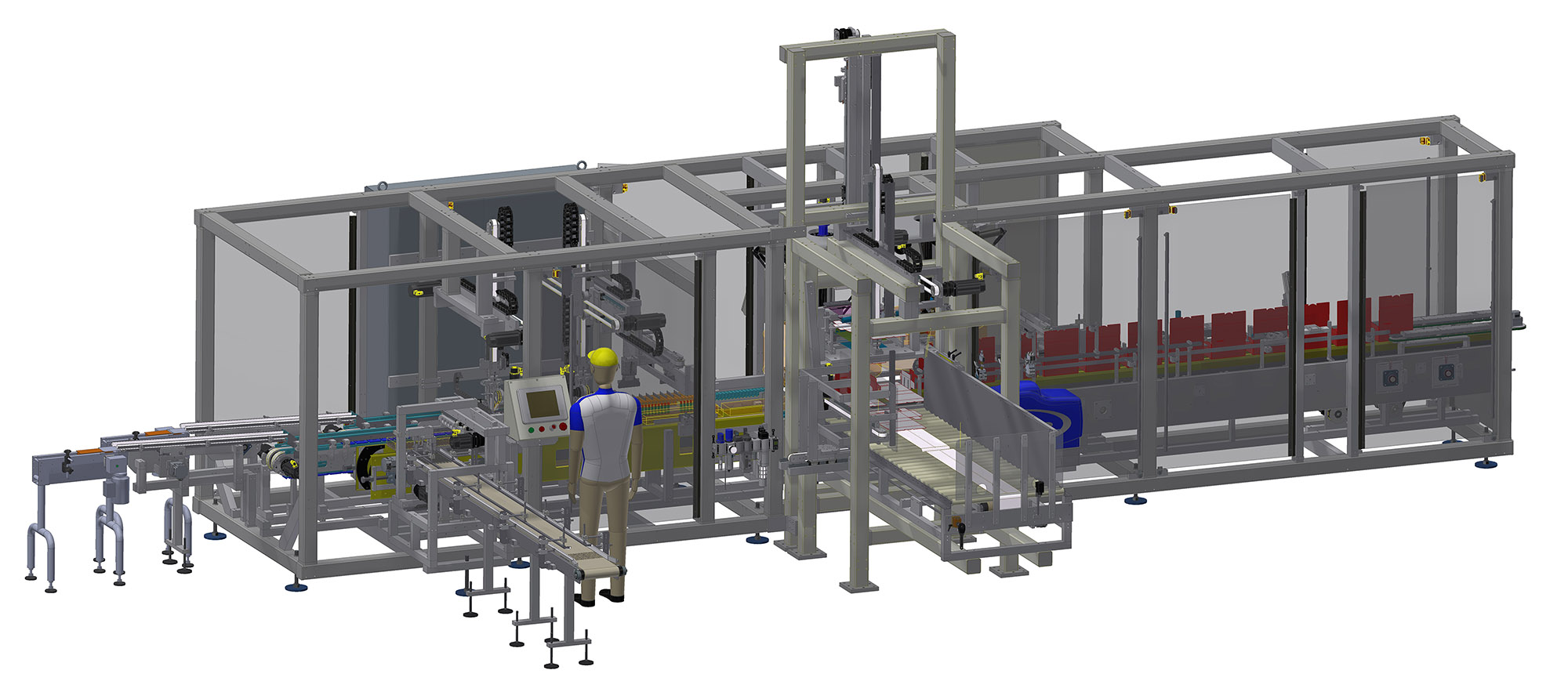

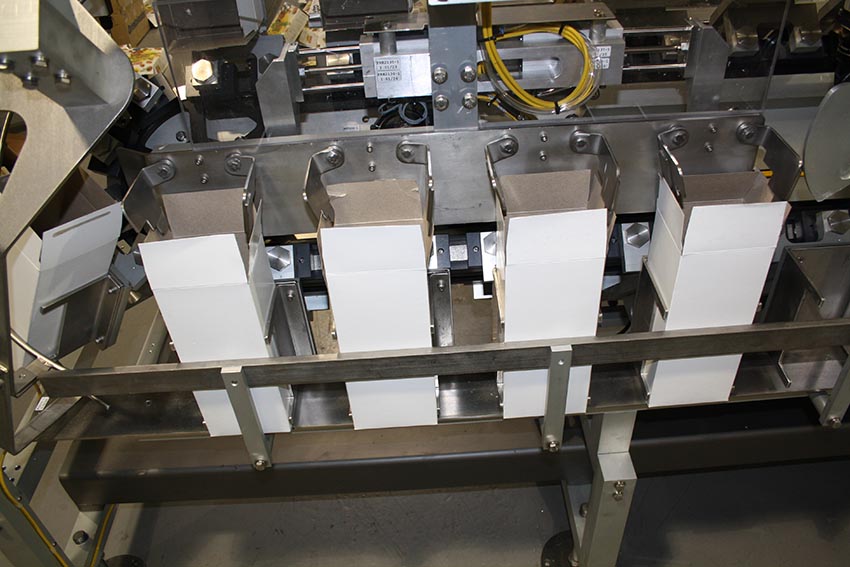

To meet customer requirements, AFA Systems designed a new machine assembly, a heavy-duty, intermittent motion autoload cartoner for bottling or vial lines. Built on a monobloc frame, the machine completes all operations within 30 square feet – about half the space typically required for a conventional multi-machine solution. The machine runs 1,200 bottles per minute.

The complex system includes six AFA Systems robots – and showcases the company’s robotic expertise. After fi lling, capping and labeling, the bottles are laid on their sides and enter the machine through two infeeds. The bottles are transported to two gantry robots via a pocket conveyor. The gantry robots pick ten bottles each – 20 bottles total each cycle – from the pocket conveyor. The robots place the bottles into a plastic tray, which holds 50 bottles. Once the tray is fi lled, a third gantry robot pushes the tray into a carton, which has been erected by another gantry robot. The carton advances to the straw packing stations.

Simultaneously, a singulator conveyor stages drinking straw packets single file for two delta robots. The robots pick the straw packets and place them on a staging plate, where they are rotated on edge and end-loaded into the carton between the rows of bottles. The carton is sealed and discharged from the machine.

Video on the machine is shown here: https://youtu.be/oEPf0XhhTQA

E.E: What are the ranges of products?

AFA SYSTEMS: Our range of products include the following:

- Cartoners;

- Case Packers;

- Tray Formers;

- Carton Formers;

- Tray Packers;

- Palletizers;

- Case Erectors;

- Case Sealers;

- Feeders and Denestors;

- Product Accumulators.

E.E: At what stage is the market where you are currently active?

AFA SYSTEMS: The markets that we sell into are at maturity. These markets include pharma, food & beverage, and household consumables.

E.E: What can you tell us about market trends?

AFA SYSTEMS: Two significant trends we see in the marketplace are machine flexibility and limited operators. End users are requesting highly flexible machines that can provide a wide range of product SKUs regarding machine flexibility. These SKUs include bulk packs, high product counts, and small sizes. Coupled with flexibility is quick changeover. End users desire a wide range of quick change over features such as push-button automatic change over. This feature ensures that production lines have minimal downtime.

The second trend is reducing operators on packaging lines. The COVID 19 pandemic has placed strains on manufacturers to find workers to package their products. Many workers are hesitant to find jobs with close person-to-person contact, such as on a packaging line. The result is that companies are now embracing automation to reduce their risk of labor shortages. Furthermore, customers are requesting less human handling of their product, resulting in an increased demand for packaging machinery.

E.E: What are the most innovative products marketed?

AFA SYSTEMS: We feel our most innovative products are our cartoning solutions. We have designed very flexible cartoning machines capable of a wide size range, complete changeovers in less than 5 minutes, and can handle multiple closures on the same machine such as tuck, glue, hanger tab, and more.

E.E: What estimations do you have for 2021?

AFA SYSTEMS: We feel that the industry will continue to grow, and there will be more opportunities in the future. We are also looking at foreign markets to expand our manufacturing capabilities and increase capacity. The global push to reduce manual labor on packaging lines will undoubtedly aid us in the foreseeable future.