Afag is one of the well-known companies with more than 60 years of experience in assembly automation. As a traditional Swiss company with branches in Germany, Switzerland, China and USA, Afag produces innovative solutions and the latest technology with the goal of meeting the high standards of the automation industry. Their sales partners are located in more than 30 countries, allowing customers around the world to benefit from an expert package of analysis, consulting, planning, and service.

Interview with Anita Renc, CSO at Afag.

Easy Engineering: What are the main areas of activity in the company?

Anita Renc: Our main activity areas are feeding, transporting and handling of parts completed by a high level engineering service to combine our components to solutions and support the customers with an over-all service package.

E.E: What’s the news for new products in 2021?

A.R: We are working on the next generation of automation products. At the moment we are not able to give you exact details, because we are in the last stages of the development process. But by the end of this year, you will see a range of new Afag products with features that allow a new method of component integration into existing plants, as quasi-autonomously working and highly integrated parts of the system.

E.E: What are the ranges of products?

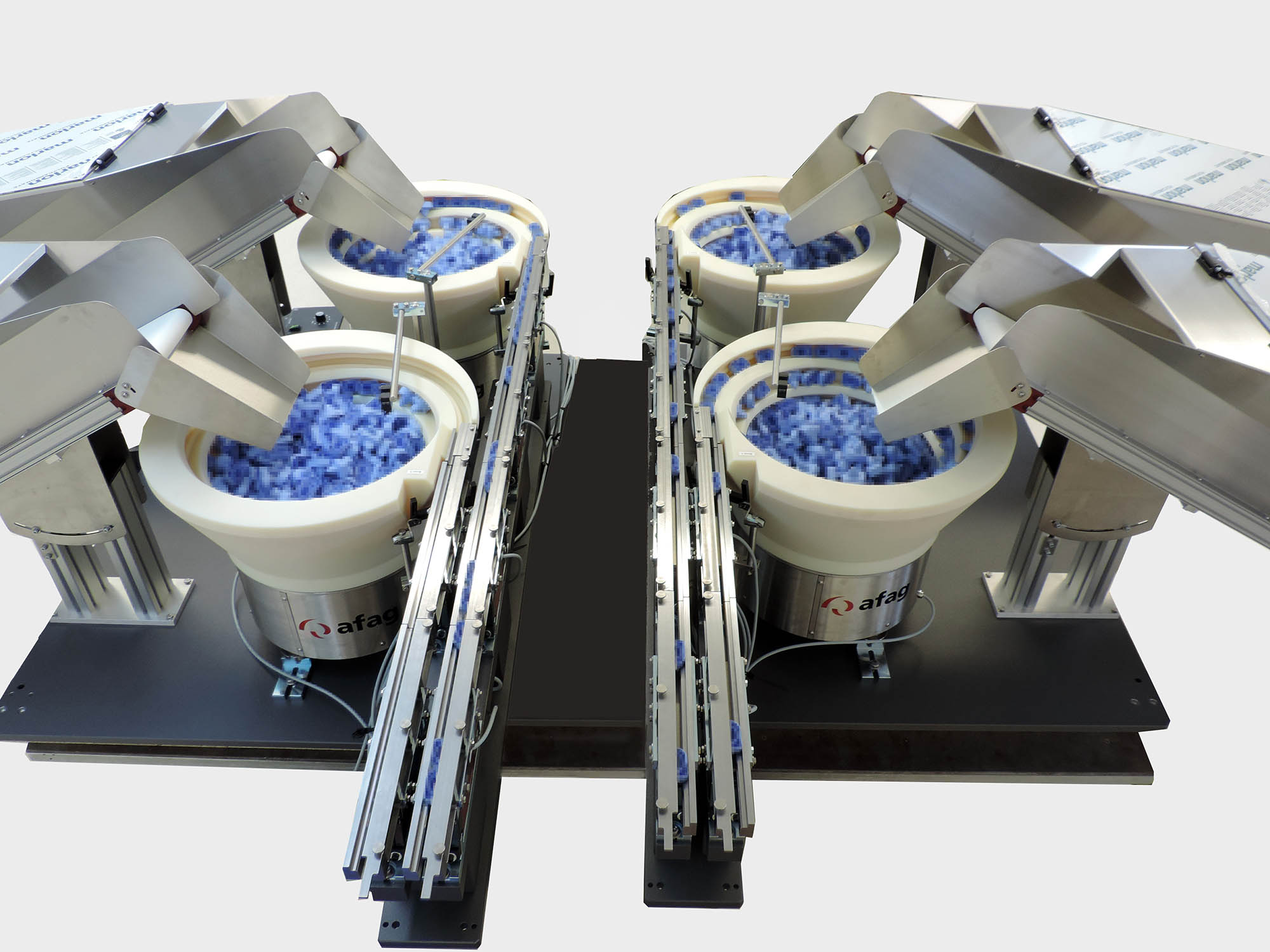

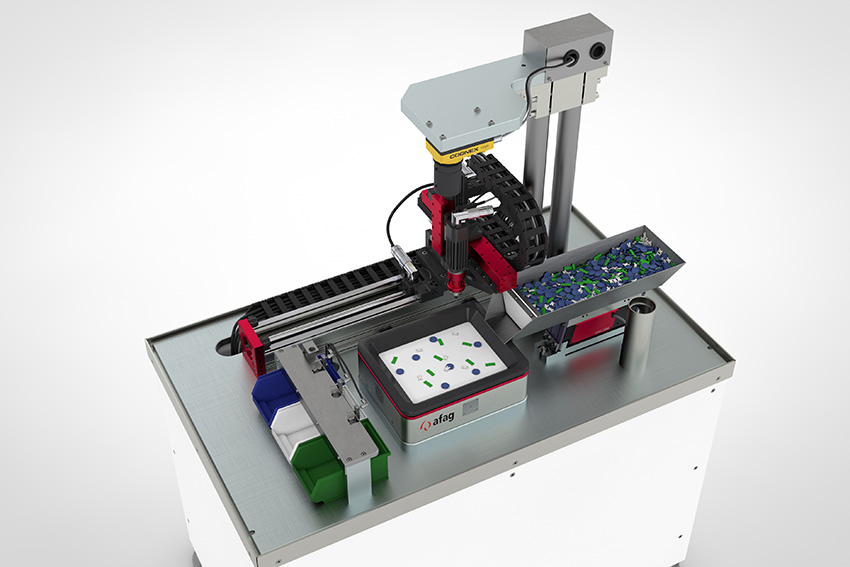

A.R: Afag is specialized in different feeding solutions like CAD/CAM based, highly precise, and reproducable feeding bowls. Including vibration compensated drives and flexible feeding solutions with the integration of camera, and robot or pick-and-place system.

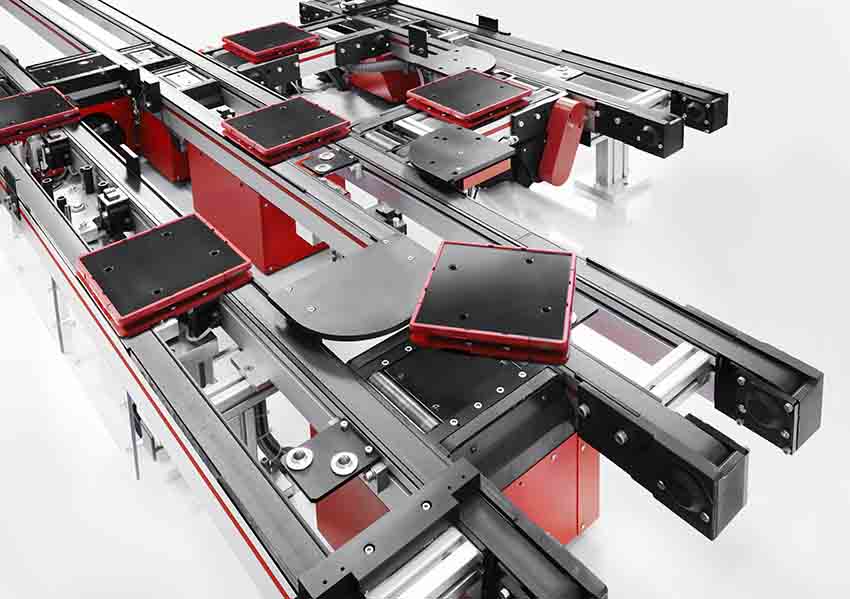

High quality transport systems of up to +/-0,05 mm placing accuracy and extremely high cycle times are offered to move the parts within the customer´s plant.

Finally, our handling systems are turning, screwing, and moving the parts quickly, with a brilliant long-term accuracy. The performance of our applications is often times better than a robot.

E.E: At what stage is the market where you are currently active?

A.R: I see the requirements in automation moving into two main directions: on one hand, towards continuously shorter cycle times and higher accuracy and, on the other hand, towards flexible solutions and cost efficiency.

The goal of the provider will be to offer the correct solutions for different applications, with a deep understanding of the technology, and a reliable support system along with advice for the customers.

E.E: What can you tell us about market trends?

A.R: The tendency or trend is moving towards mechatronic products with integrated micro-electronics or micro-mechanics and embedded electronics equipped with corresponding on-board software. Along with algorithms that generate relevant information for the customer from available data.

To enable the new way of communication, bus systems, such as OPC UA, OPC UA over TSN, AML etc. – based wherever possible on real-time communication such as Ethernet – are playing an increasingly important role.

On the other hand, where dynamic motion is concerned, the issue of functional safety will become more and more important. For example, axis controllers will have to include increasing numbers of corresponding capabilities.

Additionally, increasing dependence on software requires concepts to ensure the necessary cybersecurity in order to sustainably provide protection against corresponding cyberattacks.

E.E: What are the most innovative products marketed?

A.R: Come visit us on the Motek in October! We will be happy to show you our product.

E.E: What estimations do you have for 2021?

A.R: As of now, 2021 will be highly challenging, but a very successful year for Afag. We had to master the effects of the Corona crisis. With the compulsory break in 2020, we had to make a vertical start in sales, development, construction and production in order to meet the suddenly skyrocketing demands of the market. The challenges of the second half of the year will be to secure our need with materials and satisfy the required lead times.

Lastly, 2021 has been a great year with many new challenges and chances for the automation market.