Agriest is a wholesaler and a manufacturer of farm machinery spare parts from France. Established in 1980, the company is dedicated to OEMs and dealers. Turnover is 40 M€ and it is integrated in a group making 180 M€.

The company has their own workshop in France where they produce parts such as front loader attachments, conveyors for Muck spreaders, Tungsten wearing part. Agriest has also a subsidiary in Romania which is producing loader tines, towing eyes, and wearing parts for soil cultivation machinery

Easy Engineering: What are the main areas of activity of the company?

AGRIEST: The company is mainly selling 5 families of products:

- Farm trailer parts;

- Slurry tanker and Muck spreader parts;

- Soil cultivation machinery parts;

- Coupling and front loader parts;

- Hydraulic and transmission components.

E.E: What’s the news about new products?

AGRIEST: We have an important range of wearing parts for cultivators, ploughs and other machines.

Those parts are made with tungsten carbide. We have developed for the new season some new references for the most important brands like HORSCH, LEMKEN, VADERSTAD, MASCHIO…

Those parts are a more expensive than standard ones but they last much longer; The cost per hectare is finally cheaper.

E.E: What are the ranges of products?

AGRIEST: Among those 5 families described before, we are selling for example wheels, axles, towing eyes for trailers, some sprockets for muck spreader, coupling for slurry tankers, loader tines, hydro-clips…

E.E: At what stage is the market where you are currently active?

AGRIEST: We are operating on a mature market but we keep innovating to grow and develop our market shares.

E.E: What can you tell us about market trends?

AGRIEST: The situation is complicated at the moment and difficult to analyze.

But, because of the general price increase of raw materials such as steel, there is a very strong interest for our Tungsten carbide parts. Farmers are looking for solution to reduce their production costs.

For OEMs, the main challenge is to find some solution for the new European homologations and our innovative hydraulic brake system is a very good solution.

E.E: What are the most innovative products marketed?

AGRIEST: We develop every year some new components and many of them are awarded during international exhibitions.

Last innovative developments have been:

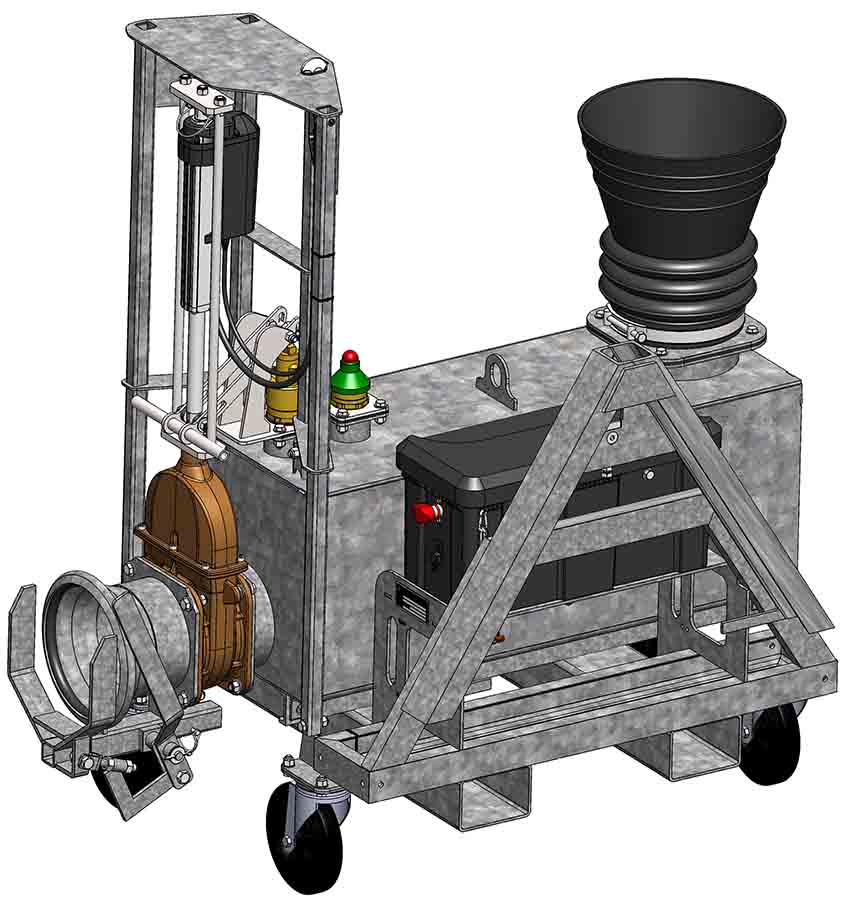

- a remote-controlled docking station;

- an innovative hydraulic brake system;

- testing set for air brakes;

- an anti theft system for machines;

- a universal towing device.

E.E: What estimations do you have for 2022?

AGRIEST: As explained, it is very hard to analyze the market. The demand is very strong but we don’t know exactly if it will remain the same as long as price of raw materials increase.