Akanthas is convinced that waste is a resource. The company helps industries (construction, manufacture, haulers, and recyclers) to digitalize waste production and optimize transports, maximize recovery and then favorize circular economy.

90% of the global waste comes from industry and construction, almost all is recyclable. Unfortunately, half finishes in landfills and 80% of waste transports are under or over loaded generating big financial and environmental gaps for producers and recyclers. These problems are related to the absence of measure and anticipation of waste production.

Interview with Viviana Contreras Moreno, Cofounder and CEO of Akanthas.

Easy Engineering: What are the main areas of activity of the company?

Viviana Contreras Moreno: Digital solutions based on artificial intelligence for industrial and construction waste management.

E.E: What’s the news about new products?

Viviana Contreras Moreno: We develop and commercialize a service based on an artificial intelligence powered software and a smart image sensor to help industries, haulers, and recyclers to increase efficiency of waste management based on waste analysis and key recommendations.

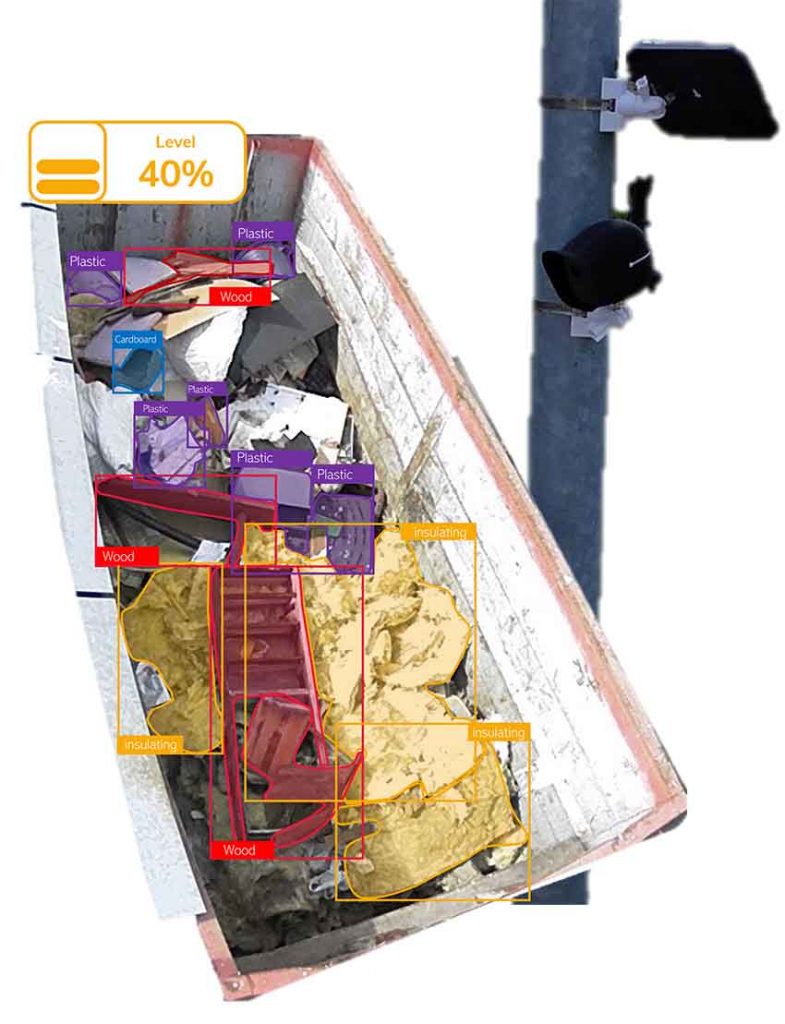

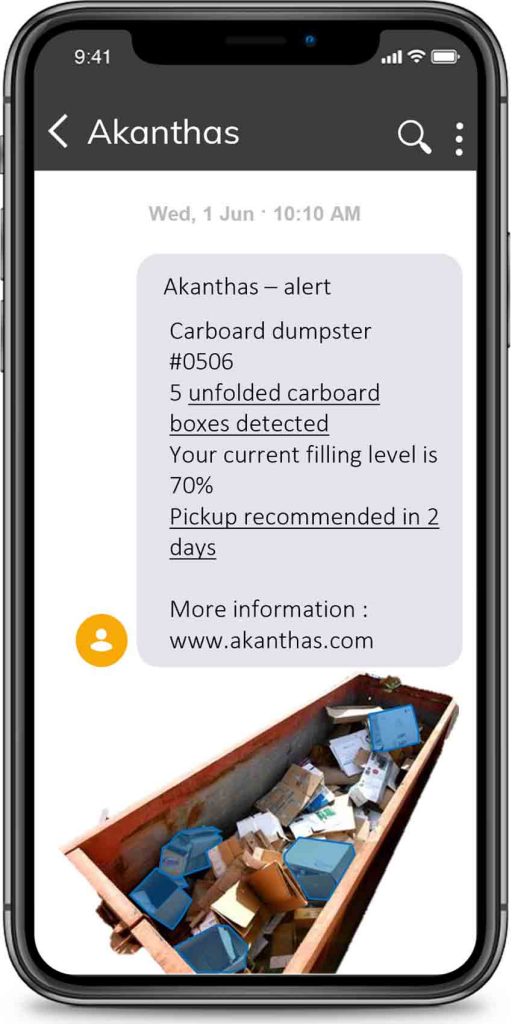

Our image sensor (“nova/Trinity®”) is completely autonomous and plug and play. It takes pictures of waste which is disposed in roll-off or zones and measures the filling level, detects sorting problems, and characterizes inside materials in real time.

This information is transformed thanks to a powerful software helping to take the best decisions.

E.E: What are the ranges of products?

V.C.M: We propose a SaaS service based on a monthly subscription as a function of the number of waste containers for construction, industrial companies and haulers and recyclers.

E.E: At what stage is the market where you are currently active?

V.C.M: The smart waste management relying on sensors is a market that has emerged about a decade ago in the municipal waste sector. It is now growing and evolving very fast and extending to the industrial waste field.

Specially, the current global material crisis shows that industrial waste are valuable resources that can be used to address the problems and give the same possibilities that virgin raw materials

We are at the perfect timing to provide a solution allowing producers and waste operators to react faster, generate profitable waste and minimize the carbon footprint produced by the exploitation of new materials.

E.E: What can you tell us about market trends?

V.C.M: The rising construction, demolition, and manufacturing waste due to rapidly increasing and global development have severely impacted the environment. Such a huge amount of waste generated by these sectors needs to be managed effectively. This is expected to accelerate the market growth in upcoming years.

Moreover, regulations around de world are changing inciting the market to find the right technological solutions. We can mention in France for example the AGEC law which forces the industries to control and verify waste and recycling and to decrease the ratio of recyclable materials send to landfills or incineration. Additionally, the European Green Deal, which aims at making the European Union climate neutral by 2050, with a large focus on waste management.

E.E: What are the most innovative products marketed?

V.C.M: Digital solutions using computer vision to recognize waste specially in the municipal waste sector (10% of the global production).

Akanthas is focused on the 90% of the waste production by using a disruptive technology based on computer vision and artificial intelligence which aims at solving transport and recycling problems of industrial materials.

E.E: What estimations do you have for 2022?

V.C.M: We launched our service and product last year. We deployed some successful pilots with different manufacture industries in France. Currently we have several clients from the manufacture, construction and recycling sectors and we expect to deploy international projects at the end of 2022.

We expect to analyze more than 300 hundred waste containers by the end of this year.

We are preparing a fundraising of 1M€ to accelerate the industrialization, scaling up and commercialization of our solution.