Altek Metal was formed in 1987 with the aim of becoming our customers’ solutions partner in aluminium procurement. Today, Altek Metal is an aluminium supplier very much in contact with the global aluminium supply chain. The company supplies products to over twenty countries, mainly in Europe and they have become an international reference point for the Turkish market.

Easy Engineering: What are the main areas of activity of the company?

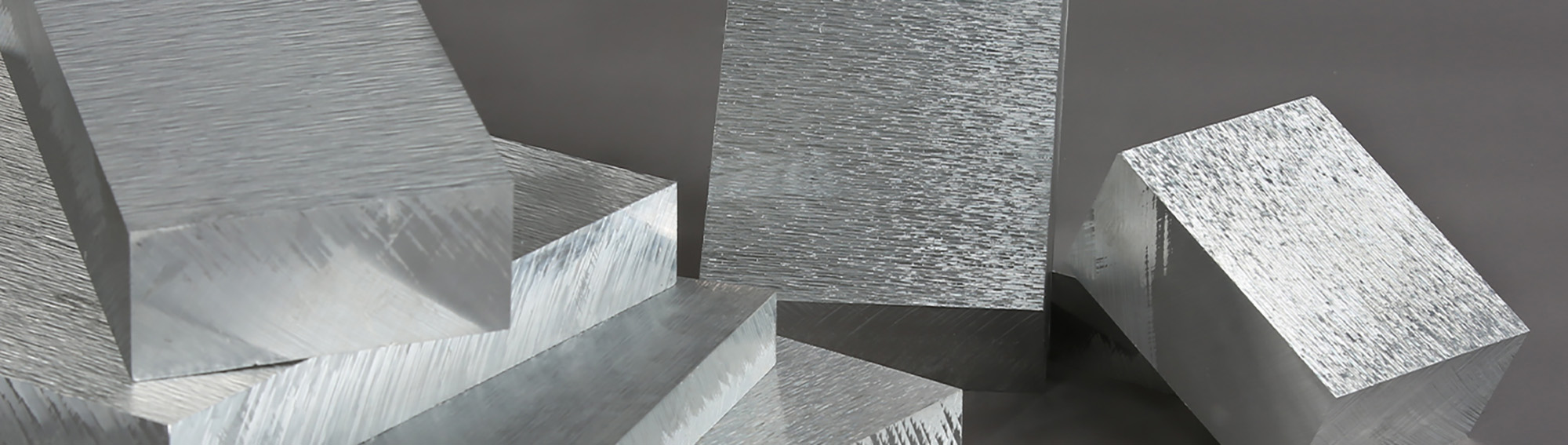

Altek Metal: As Altek Metal we specialize in the production of precision milled aluminium tooling plates and aluminium cast plates. We are the only local producer of milled tooling plates in Turkey.

Additionally, we supply aluminium rolled plates, sheets, shates, shipbuilding shates, extruded aluminium profiles and tread plates to many industrial sectors. These include aerospace, automotive, machine, mould, silo, 3D printing and tanker industries. We have a vast aluminium alloy inventory that includes grades 5083, 5754, 6061, 6082, 6900, 7075 and more.

We supply cut to size aluminium parts to optimize our customers production process. We are able to cut our products in a variety of methods including the water jet, cnc, and schelling machine. In addition we are able to cut coils to length and make round and flat bar cuttings. We have three main service and production centers as well as a retail shop in Turkey.

In 2017 we have created our online e-commerce platform aluminyumburada.com to better serve our customers in the digital age. We aim to make your purchasing experience as effortless and efficient as possible. This website is particularly useful for our European end consumers as they are able to reach the materials they require without having to place a large order.

As Altek Metal we highly value sustainability in business and environmental sustainability in particular. To reduce our carbon footprint, we have at the end of 2020 set up solar panels on the roof of our Çerkezköy service center and produce 65% of our energy requirement. We are proud to have made this first step to reduce our carbon footprint. We are working to continue reducing our footprint in the upcoming years.

Solar Panel Video to be Embed on page

E.E: What’s the news for 2021 about new products?

Altek Metal: In 2021, we have begun to service the industrial sector in Turkey with EN AW 7021 AlZn5,5Mg1,5 cast and milled tooling plates. Alloy 7021 is an in between alloy between the medium and high strength alloys.The major advantage of 7021 is its availability and continuity of supply in the 7xxx grade. Sold at a lower price point, alloy 7021 offers our customers the dimensional stability of alloy 5083 cast plates with a strength slightly lower than 7075 rolled plates. In doing so it is highly desirable product for the machine and mould industries and particularly advantageous for users who are acquiring plates in the 7xxx grade above 150 mm thickness. Currently as 7075 rolled plates are not very available, it is very costly for our customers. We believe Alloy 7021 will provide the necessary relief to our customers who are working with 7075 rolled plates.

Alloy 7021 Video to be embed on page

E.E: What are the ranges of products?

Altek Metal: Our aluminium cast plates are alloy 5083 and follow DIN EN 573-3 norms. We supply cut to size aluminium products with a cutting tolerance of +/- 0.2 mm. The maximum sizes possible are:

- Max. 600 mm in thickness

- Max. 2200 mm in width

- Max. 4020 mm in length

- Tooling Plate Video to be embed

For milled aluminium tooling plates, we once again supply alloy 5083 following DIN EN 573-3 norms. Our maximum sizes are:

- Min. 5 mm / Max. 300 mm in thickness

- Max. 2020 mm in width

- Max. 4020 mm in length

Flatness Tolerance:

- 5 -12 mm Thickness ≤0,40 mm flatness tolerance

- > 12 mm Thickness ≤0,13 mm flatness tolerance

Cutting Tolerance:

- Between 5 mm and 100 mm: +/- 0.2 mm tolerance

- Between 101 mm and 180 mm: +/- 0.5 mm tolerance

- Between 181 mm and above +/- 0.5 mm tolerance

For the full details of our products, please visit our online aluminium sale website.

E.E: At what stage is the market where you are currently active?

Altek Metal: We currently mainly supply the automotive, machine, food packaging and aviation industries. Although the demand from the aviation industry fell sharply last year due to the pandemic, all the other above industries have been stable and on a upward trend. In the automotive sector, the use of aluminium is increasing as the industry is moving towards creating lighter weight, electric, more sustainable vehicles. We believe that commercial aviation will also pick up after the pandemic.

E.E: What can you tell us about market trends?

Altek Metal: Our business is currently booming due to the deferred demand from 2020. Last year our end users reduced their inventories. However this year with a positive environment the demand has almost doubled. At the same time, the global container crisis has pushed the prices to go up and our customers are purchasing higher amounts to future-proof themselves against future crises. Although we are unsure to how long this high demand will last, it is likely that the market will not return to 2019 conditions in 2021.

Please visit our website for our full range of products or contact aluminyumburada@altek.com.tr directly for all of your additional inquiries.

Altek Metal: https://www.altekmetal.com/

Website: https://aluminyumburada.com/