Interview with Gergely Hajas, General Manager, Technician, Inventor at Alu-Öntő Ltd.

Easy Engineering: A brief description of the company and its activities.

Gergely Hajas: Our family run sand cast foundry founded in 1991 and started its activity in aluminium gravity sand cast field of the heavy industry. In the beginning the core business of activity based on production of traditional gravity sand castings and this activity still remained nowadays. So, the main point was the weight of parts – the heavier was the better.

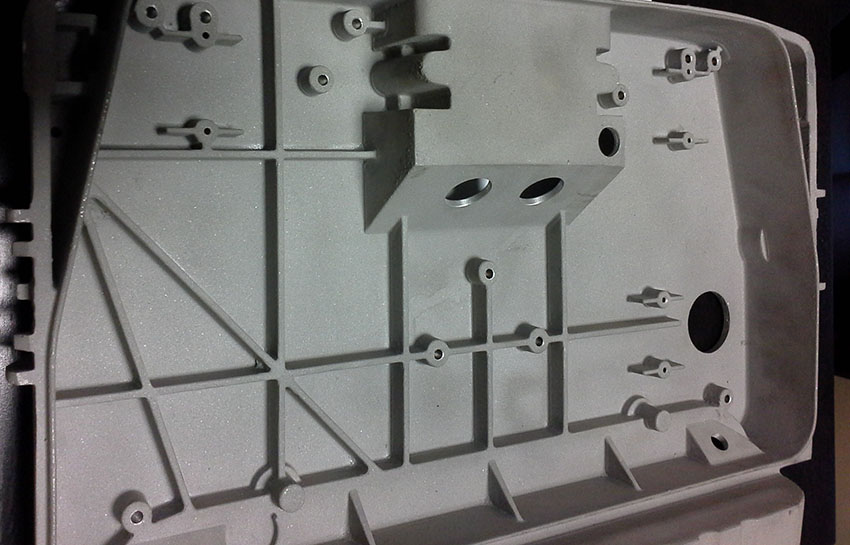

That we compared this activity is a prototype and pre-series production of aluminium thin wall /1-3mm/ gravity sand cast technology. This means that we produce large geometry, thin wall HPDC prototype parts according to its standard requirements under atmospheric pressure and with sand moulds.

E.E: What are the main areas of activity of the company?

G.H: Under a normal production process of traditional aluminium gravity sand castings, 8 years ago an American international company required us to produce aluminium sand castings but the castings geometries optimized to HPDC process and the average wall of parts were basically 3-4mm. So, the market demand was the first and we started to work according to the requirement step by step and started to create a new field of application: production of aluminium thin wall /1-3mm/ gravity sand castings in large geometries.

E.E: What’s the news about new products?

G.H: Which is very interesting: the low average wall thickness and large geometries under atmospheric pressure – in one. To cast by gravity sand a 2mm walled aluminium part more than 1000 mm long distance /1050x350x140/ is a real challenge and even the geometry have to be compact with HPDC standards. So, with this patented technology is possible to cast complex or structural aluminium casting components under atmospheric pressure and not necessary to invest in a HPDC tool if your aim is to have a limited small series or need to effect validation processes first on you would be HPDC part.

E.E: What are the ranges of products?

G.H: Up to now more than 110 different types of aluminium thin walled HPDC geometries were produced by our gravity sand cast technology and limited or small series production exceeded the 2000 pcs. The field of application so different and if I have to mention few areas: we can find automotive sector /body in white constructions, e-mobility applications/, lighting industry /led designed fixtures/, electronics industry /controller houses/- anywhere to find thin wall aluminium castings under 3mm of average wall thickness.

E.E: At what stage is the market where you are currently active?

G.H: In my opinion, if we talk about aluminium gravity sand castings and only automotive field of use /like test or limited series/ the market is presently under complete transformation – complex and/or structural components, with minimal average walls /basically 2-3mm/ in large geometries are under applications. The e-mobility trend requires lighter and mechanically increased aluminium casted components and of course in larger and in more compact design.

E.E: What can you tell us about market trends?

G.H: Bigger and bigger aluminium structural parts will be demanded in field of aluminium casting industry. In the same time the expected mechanical properties will be higher and higher.

E.E: What are the most innovative products marketed?

G.H: As we talk about a new and patented aluminium gravity sandcasting technology, we have no exact products – just what market would like to see in their developments. What we can provide to our customers is the time-saving to have their developments within few weeks, according to HPDC technology requirements.

E.E: What estimations do you have for 2022?

G.H: Is hard to say anything – one thing is for sure: we must adapt to the needs of the Market!

ALU-ÖNTŐ LTD.