Artilab is a Belgian company that produce “Fluoroplastic-Etch”. With their ready-to-use liquid Fluoroplastic-Etch® you can bond fluoropolymers (Teflon®) and you retain all the other positive properties for which Teflon® is used. After being exposed to our liquid, your Teflon® surface will accept adhesion and you can glue the surface to another material.

Interview with Philippe Van Gele, Director of Artilab.

Easy Engineering: What are the main areas of activity of the company?

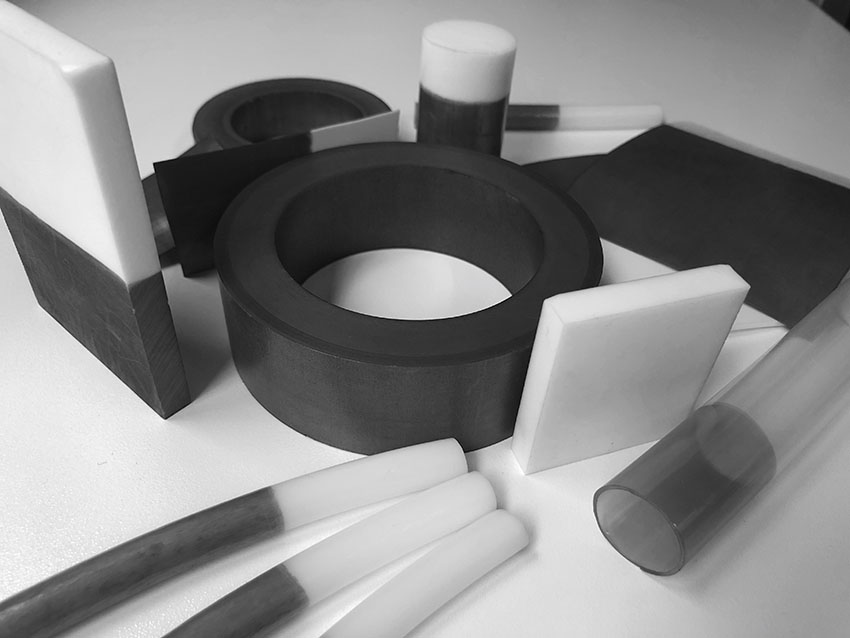

Philippe Van Gele: As Teflon® is used in almost each industry we could help with our etching product in various applications and industries. Customers could be found in automotive, space, defence and tubing.

E.E: What’s the news about new products?

P.V.G: We prefer to focus and specialize in only 1 product.

E.E: What are the ranges of products?

P.V.G: Fluoroplastic-Etch is available in standard bottles of 250 ml, 500 ml. and 1000 ml.

We also have an inhouse etching service. So, if the customer does not want to do the treatment by himself, we can do it for him.

E.E: At what stage is the market where you are currently active?

P.V.G: Teflon® is used in almost each industry, so is our product.

E.E: What can you tell us about market trends?

P.V.G: We notice growing markets as for example solar panels where they also need to bond Teflon.

E.E: What estimations do you have for 2023?

P.V.G: We used to focus before mainly in Europe. Thanks to our growing brand awareness and additional distributors we start more and more to export outside Europe. We expect a very positive evolution in this product.