ArtiMinds Robotics is convinced that the flexible usage of robots is the essential part of future production and wants to make it manageable for everyone. Their hardware-independent software technologies enable companies to simplify robot deployment and operation. In addition to software development, they offer tailored services to support customers in all phases of automation. Among the users of ArtiMinds software solutions are internationally operating manufacturing and technology companies from the automotive, electrical engineering and consumer goods industries as well as plant and mechanical engineers.

Easy Engineering: What are the main areas of activity of the company?

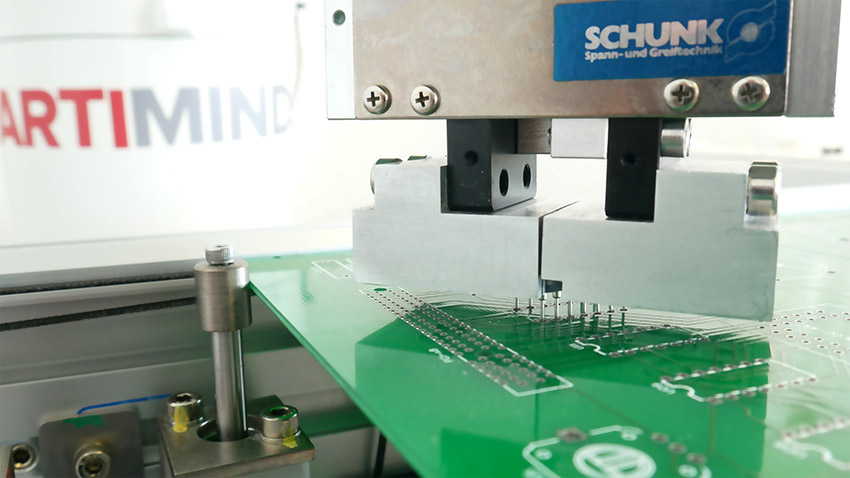

ARTIMINDS: ArtiMinds simplifies the implementation and operation of all robot-based manufacturing processes. Important application types of our customers are assembly, surface processing, quality control and handling. Robots can be used for many different applications. Particularly exciting for ArtiMinds are those that require high precision and sensitivity. These are tasks such as plugging cables, placing plastic plugs or clips, THT assembly, covering textile covers, applying sealants, polishing surfaces or even engraving, deburring and screwing components.

E.E: What are the ranges of products?

ARTIMINDS: ArtiMinds offers continuous software solutions for planning, programming and operating robot cells. Getting started is easy – no additional robot controller and special programming skills are required. ArtiMinds generates native robot code that runs autonomously on the standard robot controller. Solve challenging tasks including force control, vision sensing and PLC communication without writing a single line of robot code.

With the software ArtiMinds Robot Programming Suite (RPS), the usually high programming effort for the integration of cameras, force-torque sensors, electrical grippers and PLCs is replaced by the much simpler selection, combination and parameterization of predefined templates.

ArtiMinds RPS provides a comprehensive library of building blocks that covers a various tasks from Pick&Place to camera-based detection and force-sensitive joining of components. The user is supported with a wide range of assistance functions, such as graphical wizards, to enable optimal setup. This greatly reduced setup effort brings robot-based automation tasks into focus, which were previously economically unfeasible.

ArtiMinds RPS combines online and offline programming in one tool and thus enables a seamless transition from the planning of a robot cell, to commissioning and maintenance. Without having the real hardware setup, CAD files can be used to easily create tool paths, perform collision and reachability tests, or calculate collision-free paths. The robot program created by the planner can then be extended and put into operation on the real robot. It is possible to teach keypoints, calibrate the robot program and test the generated robot code directly in the software.

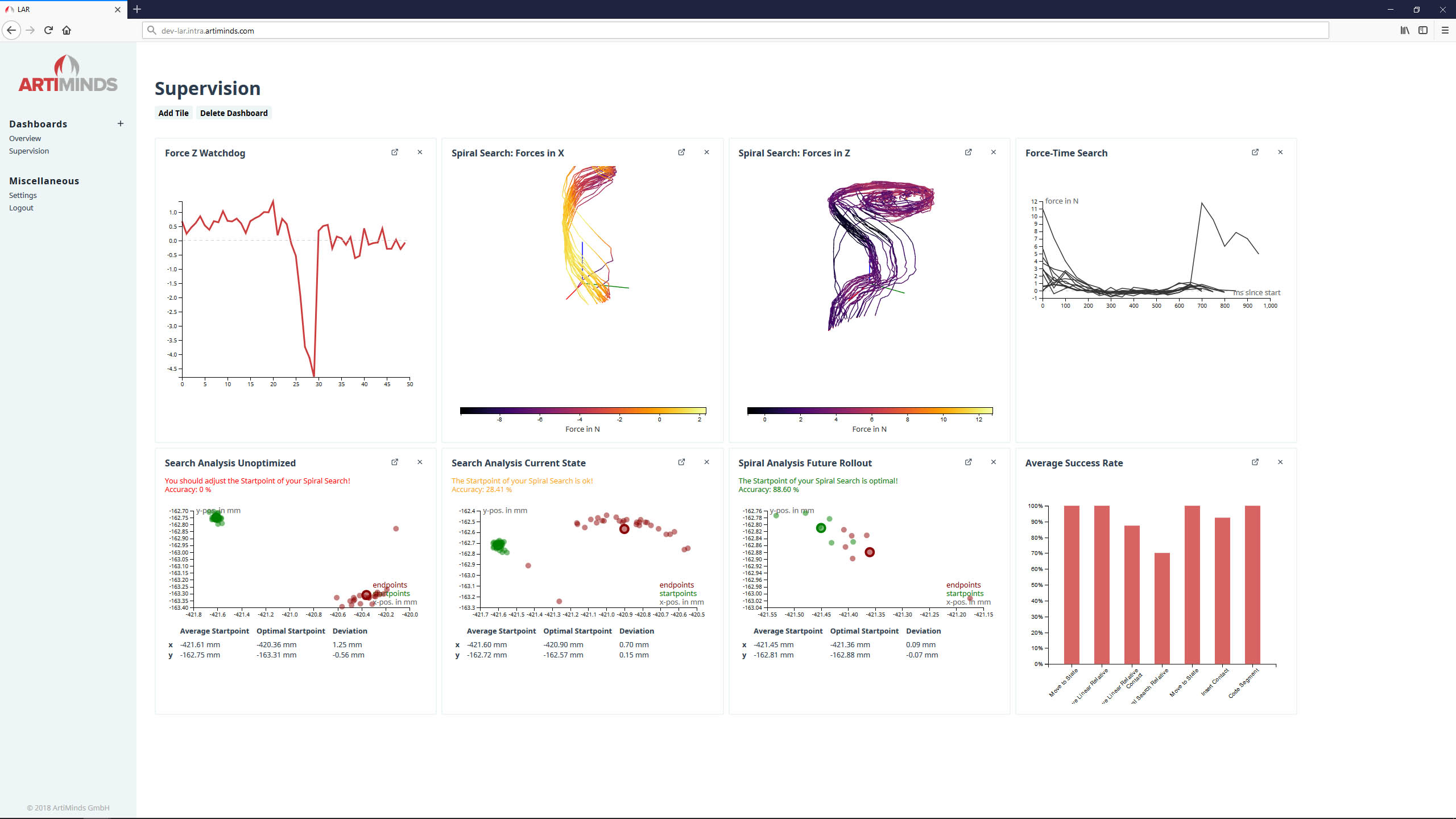

The supplementing analysis tool ArtiMinds Learning & Analytics for Robots (LAR) enables a highly detailed and process specific insight into the application becomes possible. The basis is a wealth of data such as robot movements, force-torque measurements, image processing results and error codes, which are automatically collected and stored in a local database of the user. Instead of just providing general statements about the robot, ArtiMinds LAR is a tool making it possible to evaluate data in a targeted manner, with a direct view on the individual sub-processes programmed in the RPS. Robot tasks can be analyzed thoroughly and optimized with little effort.

A transverse force during gripping, for example, represents an error condition, whereas the same transverse force is desired during assembly. This contextual evaluation offers undreamt-of possibilities and simplifies the analysis of processes. An example would be the analysis of what effects different component batches have and how one can optimize teach points in a targeted manner in order to shorten cycle times and/or to increase process reliability. Serial numbers are also recorded automatically. This allows conclusions to be drawn with regard to production quality, for example by correlating outliers detected by means of epsilon analyses with product returns using force-path diagrams.

As a web interface, LAR not only provides pure numbers and values, but also prepares them graphically and visualizes indicators. When analyzing the recorded data, meaningful evaluations are automatically suggested to the user facilitating interpretation.

E.E: At what stage is the market where you are currently active?

ARTIMINDS: The number of industrial robots and cobots in use worldwide is steadily increasing. However, the high hardware costs and complexity often prevent companies from taking the step into robotics. Therefore, solutions are needed that are economically viable, flexible to use, and easy to implement and operate.

E.E: What can you tell us about market trends?

ARTIMINDS: Current megatrends in production require ever-greater flexibility in the use of automation processes. In order to be able to meet these requirements, automation will evolve from special machine construction to standard hardware, which can be rapidly adapted to process changes or even to completely new process This process is mainly driven through software.

In other words, without software, it is not possible to implement a flexible robot-based automation. This is caused by the fact that homogenization and standardization will become more and more important throughout the entire life cycle of robotic applications, i.e. starting with planning and programming, through commissioning, optimization and maintenance, to the subsequent transfer of application know-how to other, similar applications. Software solutions such as ArtiMinds relieve engineers and operators of a large part of the technical (complex) tasks without limiting them in terms of the basic application possibilities. Examples are the use of predefined basic skills for sensor-based reflexes that automatically generate the extensive robot program logic or the automatic calculation of program improvement suggestions by machine analysis of real runtime data.

One for all. With the Robot Programming Suite (RPS), robots from all well-known manufacturers can be programmed intuitively and compatible peripheral hardware such as electric or pneumatic grippers as well as tactile or optical sensors can be used. Programming is not done conventionally, i.e. via line code, but visually using predefined application templates; Copyright: ArtiMinds Robotics GmbH und Gorodenkoff – stock.adobe.com

E.E: What estimations do you have for 2021?

ARTIMINDS: The corona pandemic made companies aware how important the topics of digitalization, automation, and flexibility are. We therefore expect an increase in the number of installed industrial robots. In order to implement advanced robotics tasks, the demand for the corresponding software solutions will therefore increase at the same time. With our various products, we offer a hardware-independent software system for the entire life cycle of robot applications. Through our integration into higher-level factory planning systems such as Siemens Process Simulate, as well as integration of interfaces for connection to PLC, PC or cloud-based runtime management systems, we also address the embedding of robot applications in broader software-driven production.