Based in Westborough, Mass., USA, Ascend Elements is a leading provider of sustainable, closed-loop battery material solutions. From EV battery recycling to commercial-scale production of lithium-ion battery precursor (pCAM) and cathode active materials (CAM), Ascend Elements is revolutionizing the production of sustainable lithium-ion battery materials.

Its Hydro-to-Cathode™ direct precursor synthesis technology produces new CAM from spent lithium-ion cells more efficiently than traditional methods, resulting in reduced cost, improved performance, and lowered GHG emissions. With fewer batteries going to landfill and a cleaner manufacturing process, Ascend Elements is taking the lithium-ion battery industry to a higher level of sustainability.

Interview with Thomas Frey, Director of Communication at Ascend Elements.

Easy Engineering: What are the main areas of activity of the company?

Thomas Frey: Ascend Elements is involved in two core activities:

- Recycling used lithium-ion batteries and Gigafactory manufacturing scrap

- Manufacturing sustainable, engineered battery materials, including cathode precursor (pCAM) and cathode active material (CAM) made from recycled lithium-ion batteries

E.E: What’s the news about new products?

T.F: Developed at Worcester Polytechnic Institute, our innovative Hydro-to-Cathode™ direct precursor synthesis technology is the world’s most efficient and economical way to return used lithium-ion battery materials to the EV battery supply chain. The key to our efficiency and reduced cost is direct precursor synthesis. Rather than extracting individual metals in series (first lithium, then nickel, then cobalt), our process extracts impurities from the combined metals and allows us to adjust the elemental composition to produce any type of cathode material specified. It is purpose-built for lithium-ion battery recycling.

Our Hydro-to-Cathode™ process recovers up to 98% of the critical battery materials in spent Li-ion batteries and scrap. With this process, we can produce new cathode material at a lower cost and with up to 90% lower greenhouse gas emissions than similar cathode made with newly mined metals.

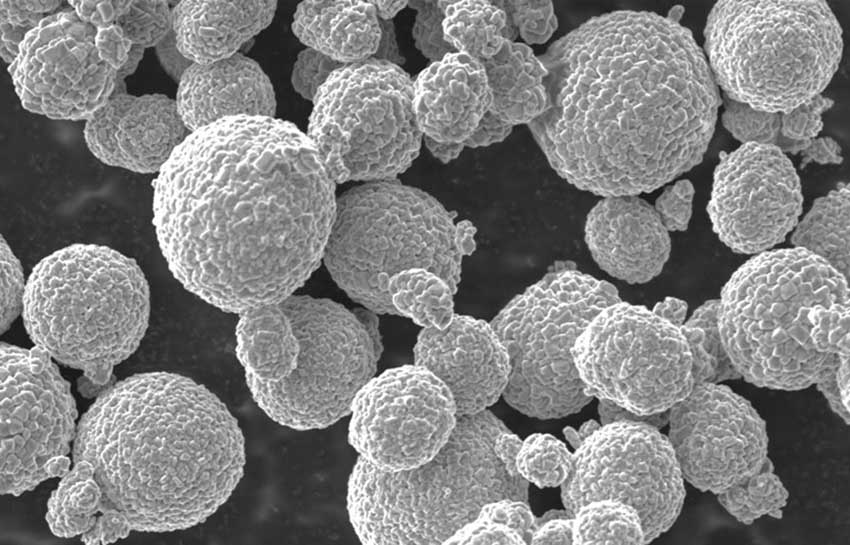

Our technology can customize and engineer cathode active material in many ways – from composition, particle size and distribution to crystallinity, morphology, and porosity – all tailored to specific customer requirements.

E.E: What are the ranges of products?

T.F: Ascend Elements manufactures a wide range of high-performance, engineered battery materials made from recycled li-ion batteries and Gigafactory manufacturing scrap.

Engineered Materials

- Sustainable cathode precursor (pCAM) made to customer specifications

- Sustainable cathode active material (CAM) made to customer specifications

- High-Nickel Cathode

- NMC 811

- NMC 622

- NMC 532

- NCMA

Raw Materials

- Recycled Lithium carbonate

- Recycled Nickel sulfate

- Black mass

E.E: At what stage is the market where you are currently active?

T.F: High Growth. In the United States, demand for recycled battery materials is increasing fast due to the growing demand for electric vehicles. Recent federal legislation – the Bipartisan Infrastructure Law and the Inflation Reduction Act – are further increasing demand for recycled battery materials. Tax credits detailed in the Inflation Reduction Act require use of domestic battery materials and recycled content in new EV batteries.

Founded in 2015, Ascend Elements is a mature start-up company. The company recently completed its Series C funding round of $300 million (equity and debt). In October 2022, Ascend Elements received two grants from the U.S. Department of Energy totaling $480 million.

E.E: What can you tell us about market trends?

T.F: The growth of the lithium-ion battery recycling industry is tied to the growth of the electric vehicle market and grid-scale energy storage market. We anticipate rapid growth in the EV battery recycling market due to increasing demand for electric vehicle batteries. Beyond recycling end-of-life lithium-ion batteries, Ascend Elements also recycles battery manufacturing scrap. Every new lithium-ion battery manufacturing facility will need a battery recycling facility of similar size.

Beyond providing a closed-loop source of battery materials, Ascend Elements is helping the EV industry prepare for the tsunami of retired and end-of-life batteries that is expected in the coming years. By unlocking the full value of used EV batteries and improving the economic return on recycling, Ascend Elements’ innovative technology may be the best way to increase recycling rates and keep potentially toxic battery materials out of landfills. This innovative technology will also play an important role in the United States’ domestic battery manufacturing and recycling infrastructure plans, as described in the Bipartisan Infrastructure Law and Pres. Biden’s recent invocation of the Defense Production Act (DPA). In the coming decades, efficient and environmentally friendly Li-ion battery recycling methods will become an essential part of America’s quest for energy independence and national security.

In fact, Ascend Elements recently received $480 million from the U.S. Department of Energy to commercialize the Hydro-to-Cathode technology at a one-of-a-kind manufacturing facility in Hopkinsville, Ky. Ascend Elements | Ascend Elements Awarded $480M in Grants from U.S. Department of Energy to Manufacture Sustainable Battery Cathode Active Materials.

E.E: What are the most innovative products marketed?

T.F: The co-founders of Ascend Elements are commercializing an innovative recycling technology that transforms used lithium-ion batteries and manufacturing scrap into new, sustainable cathode active material (CAM) used to make new electric vehicle batteries. With global shortages of the critical metals required to make electric vehicle batteries – lithium, cobalt and nickel – this new technology promises to provide carmakers and battery manufacturers with an affordable and sustainable source of battery-ready materials. Importantly, the sustainable cathode active material produced via Ascend Elements process was independently studied by the United States Battery Consortium (USABC) and found to perform as well or even better than similar materials made from newly mined metals.

The new technology recovers up to 98% of the critical metals in used lithium-ion batteries and manufacturing scrap and holds the potential to minimize the need for mining, which causes many environmental and societal challenges. Since our patented Hydro-to-Cathode™ technology is significantly more efficient than traditional forms of battery recycling, Ascend Elements can produce battery-ready cathode active materials at a lower cost and with up to 93% lower greenhouse gas emissions. Our technology enables us to recycle any type of lithium-ion battery, from cell phone and laptop batteries to electric vehicle batteries and manufacturing scrap. Battery chemistry doesn’t matter. We can take in 10-year-old batteries and produce new, high-performance cathode material with the latest NMC ratio. In addition to lithium, nickel, cobalt and graphite, we are also recovering plastics, aluminum and copper during our recycling processes. Our goal is to recover every last bit of recyclable material and keep 100% of batteries out of landfills.

E.E: What estimations do you have for 2023?

T.F: In 2023, we will celebrate the grand opening of our Base 1 battery recycling facility in Covington, Georgia, USA. We will also continue construction of our Apex 1 battery recycling and sustainable cathode manufacturing facility in Hopkinsville, KY. We are also exploring opportunities to expand into Europe and may announce new projects in 2023.