Assis-tec has been providing electronic and mechanical support on machine tools with CN Fanuc and Mitsubishi for more than 25 years.

Assis-tec is a company of 30 people, who work every day to solve technical issues in mechanical workshops and to improve production through the implementation of robotic solutions.

Interview with Massimo Mora, Sales Manager at Assis-tec.

Easy Engineering: What are the main areas of activity of the company?

Massimo Mora: We have 6 business units:

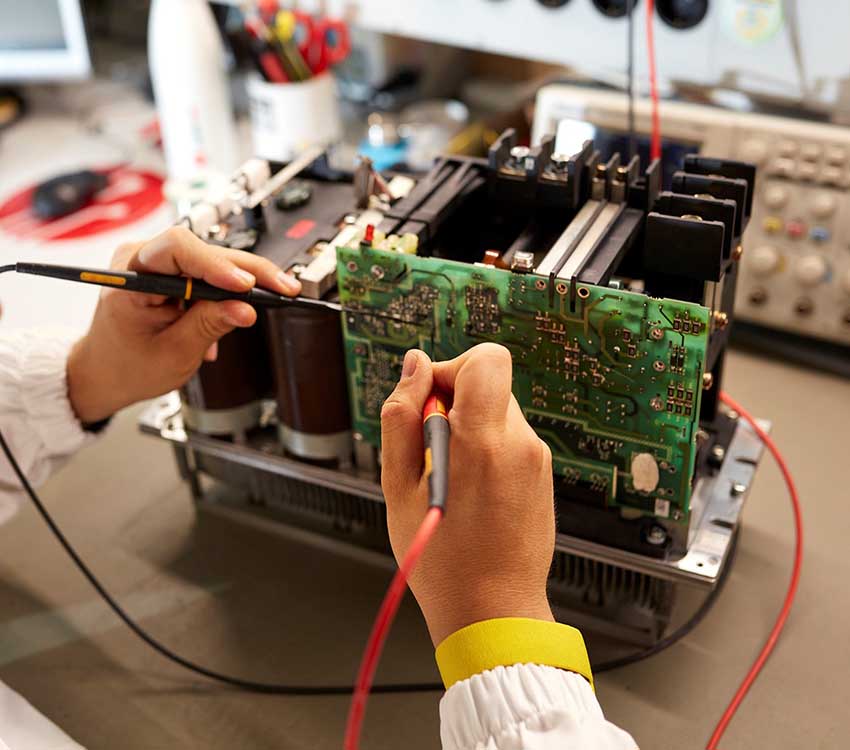

- Electronic technical Support for CNC machine tools

- Mechanical and Technical Support for multi-brand machine tools

- Electronic repair workshop

- Mechanical repair workshop

- Sale of electronic and mechanical spare parts

- Design and construction of Robotic Islands

E.E: What’s the news about new products?

M.M: For three years Assis-tec has invested significantly in the Robotics Business Unit.

In addition to the design and construction of “custom” islands, we have also developed ready-to-install and industrialised robotic solutions that can meet the main requirements of today’s mechanical workshops.

E.E: What are the ranges of products?

M.M: There are 4 product ranges:

Robofeed series A: for loading/unloading and manipulation in the various machining phases of small to medium sized, non-stackable parts

Robofeed series S: a range of solutions with the same functions as the Robofeed series A, but dedicated to stackable parts up to 250 mm in diameter

Robofeed series C: our collaborative robotic system for perfect human-machine interaction

Robofeed Custom: design of custom robotic islands, built and installed according to customer specifications.

E.E: At what stage is the market where you are currently active?

M.M: Our market is currently abuzz with activity, the economic recovery of the manufacturing industry, after two years of pandemic, is increasingly calling for technical and professional services to support the production activities. We are recognised as a leading Italian provider of technical support, electronic and mechanical repairs and spare parts for CNC machine tools.

Our Robotics Business Unit is growing steadily. The market appreciates our service-oriented approach and our ability to satisfy customer needs.

E.E: What can you tell us about market trends?

M.M: Our reference market demands fast service and professional results.

The Mechanical Workshop is increasingly interconnected and integrated with all the other company departments. The technician who works in this scenario must be constantly updated and trained in order to have the best tools to meet the customer’s needs.

Digitalisation is the new step of industrial automation, which is why we are also equipped to provide remote support, through tele-assistance.

E.E: What are the most innovative products marketed?

M.M: At the moment, the focus is on applications for collaborative robotics.

The Cobot makes it possible to create mobile robotic islands that can be retooled quickly.

In this way the robotic application can be adapted to small production batches, and even allows the operator to return to use the machine tool as often as necessary, as with our Robofeed C20.

E.E: What estimations do you have for 2022?

M.M: In 2022, we plan to further strengthen our offer in the field of robotics.

After having established partnerships with leading manufacturers in the sector (Fanuc, Schunk, Ixon, just to name a few), we will be presenting some highly innovative solutions.

Among these, we would like to highlight the “RC2” robot cell for the automated loading/unloading of the machining centre. The robot is able to pick up, from a special magazine, several self-centring vices, install them directly on the wrist, load the piece to be worked and position everything directly in the machine, also checking its clamping.

Web: https://www.assistec.cc/en

Facebook: https://www.facebook.com/assistecsrl