For more than 100 years, Atlas Material Testing Technology has been the global leader in material durability testing. Atlas’ primary specialty of weathering and lightfastness testing is a small niche, albeit an important one for many industries. Atlas offers a comprehensive line of weathering and lightfastness testing instrumentation where everyone can find the right equipment for their application from small benchtop models to extra-large stand-alone devices. A network of worldwide laboratory and outdoor testing services complements the equipment offerings.

Easy Engineering: What are the main areas of activity of the company?

ATLAS MATERIAL TESTING TECHNOLOGY: What we do can best be described with our slogan “We test everything under the sun”. Our mission is to enable every product development team across the globe to make the best material choice for a certain product in the shortest possible time. In other words, we help them to accelerate their expertise in developing world class products and take advantage of reduced time to market. Furthermore, we enable product developers to make reliable product lifetime estimates under conditions representative of the locations in which their product(s) will exist, which can be anywhere from dry desert climates with extremely high levels of UV to hot humid subtropical locations with high levels of UV, and everything in between. When considering material testing, one must also remember that materials with service lives indoors also experience environmental stressors. Interior materials are exposed to indoor solar environmental stress from natural sunlight filtered through window glass and manufactured light sources that may be present in their vicinity. As these materials won’t experience degradation effects of rain like outdoor materials, testing to indoor environmental parameters is referred to as “lightfastness” testing. Major applications are automotive interior parts, flooring, furniture, building materials, and textiles. Big trending applications are electronics, photovoltaics, consumer goods, food and beverage, and aerospace interiors.

E.E: What’s the news for 2021 about new products?

ATLAS MATERIAL TESTING TECHNOLOGY: Since the outbreak of the global COVID-19 pandemic, UVC radiation has increasingly been used to disinfect surfaces with which we may come into contact in everyday life. Today, UVC disinfection is carried out by autonomously acting robots, or with hand-held devices both in public and at home in out private areas. The surfaces are sometimes exposed to UVC radiation several times a day. The high radiation energy is on the one hand a blessing, as it kills viruses and bacteria, while on the other hand it is a curse for plastics and coatings, which can age unnaturally fast due to UVC radiation. “How do we check product resistance to UVC?” was last year’s big question. We reacted quickly and developed the Atlas UVCTest, the first UVC durability tester available since September 2020.

Since Atlas products must be always up to date regarding latest international or OEM specific weathering test methods, we also offer regular product specific enhancements. A few examples are a chiller unit for sub-ambient temperature testing of pharmaceuticals, a new filter inside an Atlas Ci Weather-Ometer® for modern automotive exterior testing, or a larger easier-to-use touch screen display as just recently implemented into our SUNTEST® and Xenotest® product lines.

E.E: What are the ranges of products?

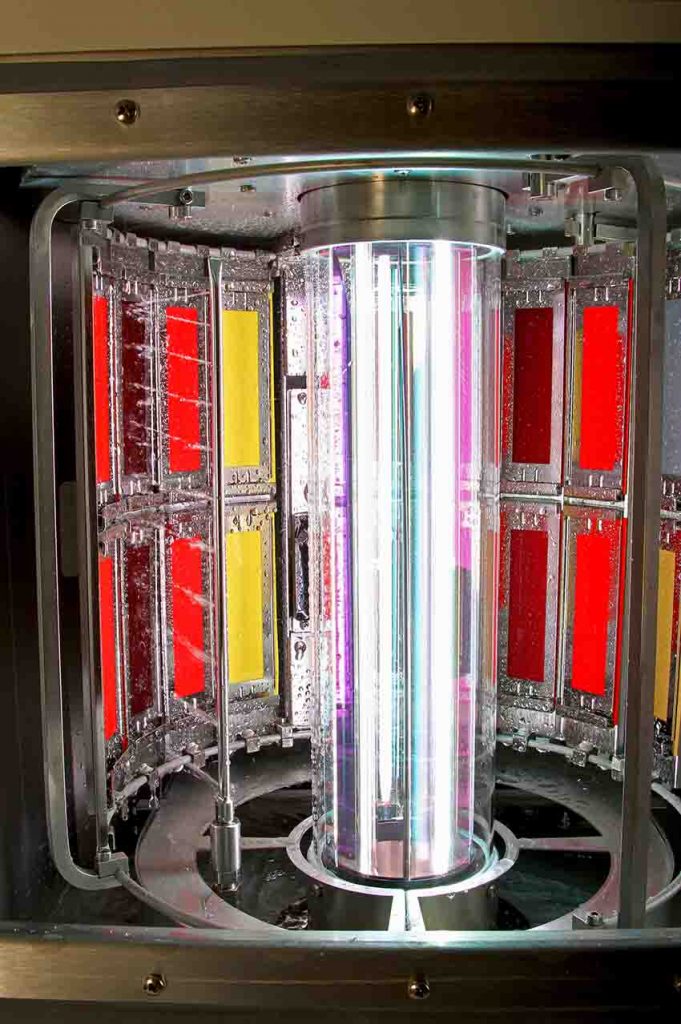

ATLAS MATERIAL TESTING TECHNOLOGY: The heart of every weathering and lightfastness device is the integrated solar simulator. The solar simulator can either be a full-spectrum light source encompassing all wavelength ranges occurring in natural sunlight (295-2500 nm), or it can be focused on one wavelength range such as devices based on providing UV radiation only (295-380 nm). The full-spectrum devices are based on filtered xenon technology. Our xenon instruments are the Ci Weather-Ometer®, SUNTEST®, and Xenotest® product lines. The Ci Weather-Ometers® are our flagship rotating rack product line that is comprised of fully functional universal product testers ranging from the Ci3000 which is our smallest rotating rack device, to the mid-sized Ci4400, and up to the extra-large Ci5000 which can test more than 110 samples simultaneously. The SUNTEST® product line consists of our compact flat-tray models that are ideal for testing 3-D products such as plastics, cosmetics, or electronics to name a few. The Xenotest® instruments are economic small to mid-size weathering devices that are useful when you have lower capacity needs, and they are often used for color lightfastness testing. While Xenotest® 220 is dedicated for testing textiles, the Xenotest® 440 is ideal for plastics and coatings.

We also offer UV cabinets for those that wish to test only in the UV wavelength range. The UVTest and new UVCTest make use of different UV fluorescent lamps with peak emissions in different parts of the UV spectrum to simulate various end-use environments of materials. The UVCTest™ utilizes UVC-254 lamps to align with commercial UVC lamps that are used for sterilization. The UVTest can be used with UVB-313 lamps to simulate radiation that occurs in the upper atmosphere of Earth, UVA-340 lamps to simulate terrestrial UV outdoors, and UVA-351 lamps to simulate indoor UV from fluorescent lamps.

E.E: At what stage is the market where you are currently active?

ATLAS MATERIAL TESTING TECHNOLOGY: Material durability testing is a mature market existing for more than 100 years. We serve many industries that have long established the need for this type of testing, such as paints and coatings, automotive, and building materials and since testing is critical to the success of products in these industries, the market is rather stable. We also serve new and emerging markets, like consumer electronics, that are coming to the realization that material durability testing is critical to their long-term success. We constantly come across both old and new companies with innovative products that have a need for our services and that fuels our organic growth across many markets, applications, and industries. When one market might be slowing down, we will see growth in another market, and that is why keeping on top of new developments across all industries we serve is crucial to our success.

E.E: What can you tell us about market trends?

ATLAS MATERIAL TESTING TECHNOLOGY: As mentioned previously, UVC testing is a trend that we expect to continue for years to come. When you Google “UVC testing equipment” for example, you get more than 5 million results, and the number is increasing daily. Another trend impacting our business is E-mobility and autonomous vehicles. Both are heavily involved in electronics and communication technology, which have led to an increase in activity in those sectors, as well. As we all know, the number of components inside of vehicles are increasing rather than decreasing, and dashboards and cockpits are full of modern displays.

Another electronics related trend is wearables—electronic devices that can be worn as accessories or embedded in clothing. The market has shown large growth over past few years and product diversification is still progressing. While fitness trackers started the trend, wearables have become further established in fields such as healthcare and medicine (blood sugar/pressure, emergency calls, hearing aids), smart shoes, and augmented and virtual reality. Although wearables designers are aware of the harmful effects of UV radiation, there is a lack of suitable weathering and lightfastness test methods. We help them to develop their own tailored test methods and support them to establish ideal testing protocols.

E.E: What are the most innovative products marketed?

ATLAS MATERIAL TESTING TECHNOLOGY: Apart from the Atlas UVCTest, the Ci4400 Weather-Ometer is our most innovative product. We managed to increase the sample capacity while decreasing the footprint compared to its predecessor, the Ci4000. The sleek new design has allowed us to tighten irradiance and temperature uniformity to +/- 2-3%. We also improved the user experience by adding an extra-large touchscreen display and modern online data acquisition services with Atlas’ latest WXView II software. The best-in-class just got even better.

E.E: What estimations do you have for 2021?

ATLAS MATERIAL TESTING TECHNOLOGY: 2021 is already proving to be a great year for Atlas. We recognize that being the leader of this industry involves not only innovation of instrument technology and enhancing performance, but also dedication to our customers by actively helping, training, and educating them every day. We are constantly feeding our clients and partners with educational content covering many topics in the world of weathering and its hundreds of applications. We prepare new content on a monthly basis where we try to address both the “how-to?” testing questions and the challenges of new trending applications. International communication via video platforms has been part of Atlas-DNA since 2007. What started with a small online seminar program has expanded step-by-step and generated a real boost during the pandemic start in early 2020. Today, we offer a rapidly growing number of online courses in various formats on special/trending topics in all time zones and in several languages. As we know, language is key to understanding, especially in the technical field of weathering. Therefore, we are not limiting ourselves to English, but also offer seminars in Chinese, German, French, Spanish, and more. We have also recently opened e-commerce sites for purchasing consumables that we expect to help with ease of business for our customers.