Automatic-Systeme Dreher is the leading systems supplier for automation solutions in production processes in the forming technology sector.

With a team of around 200 highly qualified employees, DREHER Automation plans, develops and automates forming systems, especially forming presses in the field of sheet metal and forging. The German company is the right partner for innovative automation solutions for a wide range of forming processes (e. g. cutting, embossing, deep drawing or drop forging).

Interview with Claus Dratz, Sales Director Southern Europe/Mexico at Automatic-Systeme Dreher GmbH.

Easy Engineering: What are the main areas of activity of the company?

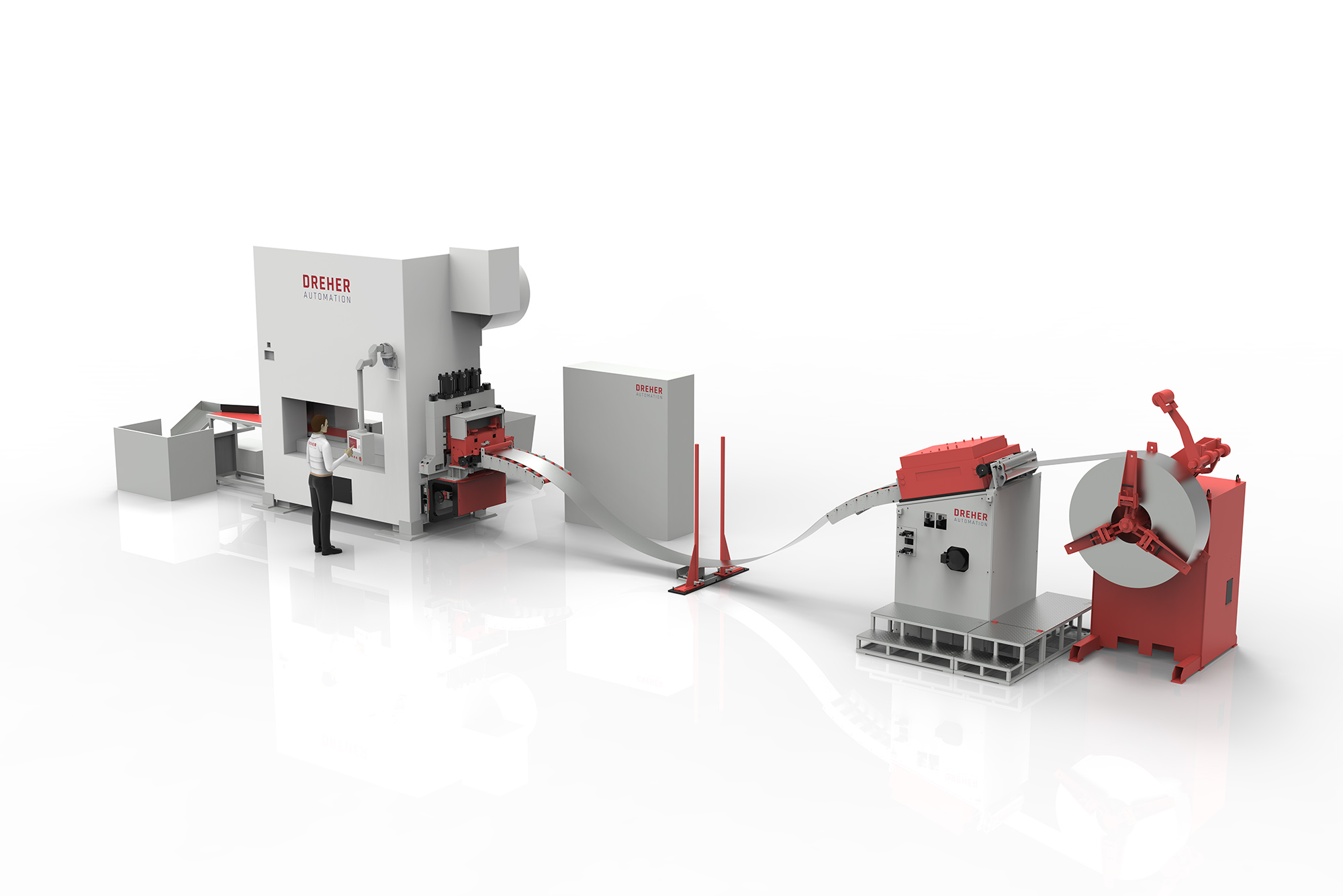

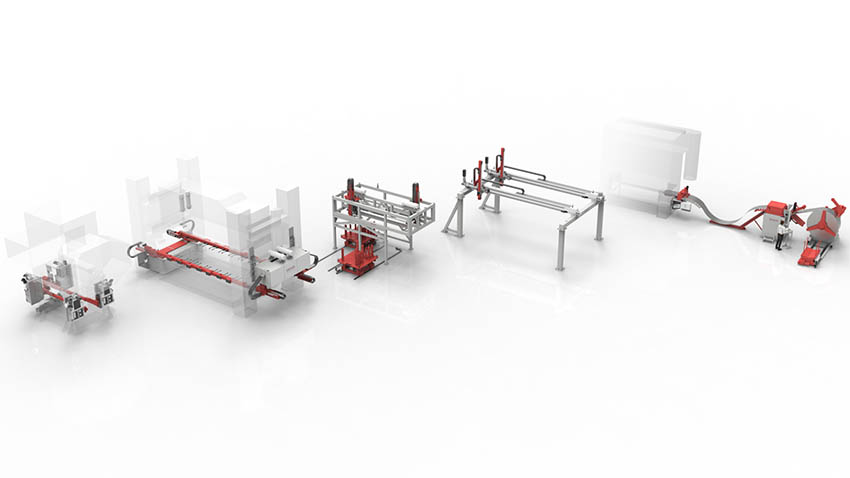

Claus Dratz: A highly efficient future-oriented manufacturing process with maximum output is the core competence of Automatic-Systeme Dreher GmbH. And whether coil handling or blank handling, the broad product portfolio in the area of press automation enables holistic solution approaches. The advantage for the customer: He gets a coherent overall concept from a single source.

For DREHER Automation, the focus is always on the customer’s products and the question of how to achieve a return on investment as quickly as possible. The basis for this is above all a sustainable and long-term partnership with its customers. This is what especially the automotive, electrical, furniture and white goods industries have appreciated about the owner-managed company for more than 50 years.

E.E: What’s the news about new products?

C.D: To keep the finger on the pulse of time, the Automatic-Systeme Dreher GmbH is involved in research into new technologies. In order to transfer such technologies into the forming technology sector, the company works closely together with its customers. Thanks to its large engineering team of around 50 engineers DREHER Automation is the right partner for the production implementation of new products (e.g., in the fields of electromobility and fuel cells) and for the implementation of new production concepts (e.g., high-speed laser blanking and additive manufacturing). Therefore, the company is not limited to specific applications. Because of the experiences in special machine constructions DREHER Automation is able to adapt flexibly to its customer processes and products.

E.E: What are the ranges of products?

C.D: With focus on the entire forming process, DREHER Automation supplies not only press automation, but also turnkey forming systems, including stamping presses, blanking lines, press lines, and transfer presses with coil processing lines or blank destackers. A secure foundation for such large-scale projects is not only a broad product range (including coil handling, blank handling and parts handling), but also a excellent project management throughout the entire implementation process.

Therefore, the Automatic-Systeme Dreher GmbH does not differentiate between new investments or modernisations. The company always keep one eye on the existing machinery in the press shop of its customers. Because although the demands on machinery are constantly rising, but it is not always necessary to invest in a new forming press. As an alternative to purchasing a new press, DREHER Automation offers a press retrofit of existing forming presses to solve the challenges of tomorrow.

E.E: At what stage is the market where you are currently active?

C.D: The last four years have been challenging for the forming technology market, with various crises impacting the industry. The troubles started in 2019 when the automotive industry was hit by a significant downturn. However, the situation worsened in 2020 and 2021 with the COVID-19 pandemic including the resulting difficulties in the supply chains and in 2022 the Ukraine war further exacerbated the situation. Despite the challenging market conditions in recent years, DREHER Automation has remained resilient. Thanks to a combination of smart decision-making, financial prudence, and a focus on innovation, the company has been able to position itself for future growth. The focus on innovation and investment in new technologies has put the Automatic-Systeme Dreher GmbH in a strong position to continue to grow and thrive in the years ahead. After years there are now first signs of a slight market recovery. For this reason, the German machine manufacturer also decided to intensify its activities in the Balkans. DREHER Automation believes in the strength of this region and has already established sales partnerships there.

E.E: What can you tell us about market trends?

C.D: The current market trends in the forming technology market revolve around new propulsion technologies, such as electric motors and fuel cells, as well as sustainability and reliable supply chains. There is a growing demand for more environmentally friendly products, and as a result, companies are investing in developing new products that are cleaner and more efficient. Companies are also looking for ways to reduce their carbon footprint and operate in an eco-friendlier manner. And last but not least, there is an emphasis on creating reliable supply chains, because of the experience of the recent years. A sustainable partnership between customers and suppliers is regaining importance again after a long period of globalisation and maximum price focus. By concentration on these key market trends, the Automatic-Systeme Dreher GmbH is able to position itself for success in a rapidly-evolving market.

E.E: What are the most innovative products marketed?

C.D: In today’s rapidly-evolving market, there is no single innovative product that can dominate. Currently various disruptive technologies are being developed and implemented at the same time. They create a highly competitive environment for DREHER Automation and all other marketers. Rather than a single product or manufacturing process, there are many different approaches to innovation, each with its own unique benefits and drawbacks. This means that companies must be nimble and agile, able to adapt to new technologies and approaches quickly to stay ahead of the curve. The most successful companies are those that are able to tailor their products and manufacturing processes to meet the ever-changing needs of the market. By remaining flexible and innovative, companies can continue to thrive in today’s highly dynamic business environment. Automatic-Systeme Dreher GmbH sees itself here as a reliable partner for mastering the current challenges.

E.E: What estimations do you have for 2023?

C.D: Looking ahead to the rest of 2023, we expect the market to rebound and reassurance after a period of instability and uncertainty. While there may still be insolvencies among market companions, the Automatic-Systeme Dreher GmbH is cautiously optimistic about the future due to the opportunities presented by new technologies. Companies, like DREHER Automation, that are able to adapt and innovate will be well-positioned to take advantage of these opportunities. However, it will be important to remain vigilant and to stay abreast of emerging trends and technologies in order to remain competitive. Also, the global political situation will continue to influence the economic framework conditions. Whether it will have a positive or negative effect is unfortunately impossible to judge from the current perspective.