To fulfil your individual requirements as a manufacturer of rubber and plastic moulded parts and non-ferrous metal parts, we give you the highest level of flexibility. This means, that with us, you receive exactly the machine, that is precisely adapted to the requirements of your operation. You determine the specifications – we build the right system. In the design, size, capacity and accessories, that you require. AW Maschinen- und Anlagentechnik offers you the full range: the entire production chain can be covered with our systems portfolio. First deflashing, then washing, and finally drying. In combination with our comprehensive spare parts service, you therefore benefit from the highest degree of reliability and the quickest possible readiness for use

Interview with Christian Klein, CEO of AW Maschinen- und Anlagentechnik

Easy Engineering: What are the main areas of activity of the company?

Christian Klein: Development and Manufacturing and Service of machines for:

- Cryogenic Deflashing of rubber and plastic moulded parts and non-ferrous metal parts.

- Washing and drying of rubber and plastic moulded parts and non-ferrous metal parts.

- Service and spare parts for all cryogenic deflashing machines.

E.E: What’s the news about new products?

C.K: AW SmartControl

New generation of control system with interactive data management via Smartphone, Tablet or PC. Optimization of process (cooling times and blasting times). Handling of order information and process data.

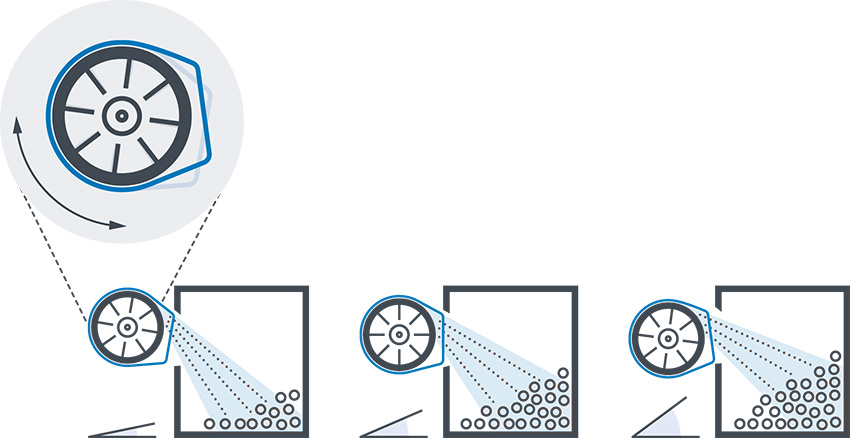

AW SmartShot

Innovative media-blasting angle adjustment – patented in combination with high speed blasting for most effective and economic deflashing. New generation of internal sieving of shot media with high-performance vibration technology and shot media conveying with lowest friction with spiral screw technology for less granulate consumption.

AW SmartCool

Low tec consumption measurement for liquid nitrogen consumption, 120mm high quality machine insulation in combination with a process optimization with reducing the cooling time for less liquid nitrogen consumption.

AW SmartWash

High pressure washing for highest cleanliness with very low water and energy consumption for a environmental and economic washing of parts.

E.E: What are the ranges of products?

C.K:

- Cryogenic blast deflashing machines

- Cryogenic drum deflashing machines

- Washing and drying machines

- Coating machines

- Service and spare parts

- Shot media

E.E: At what stage is the market where you are currently active?

C.K: Market leader in the rubber industry for our portfolio.

E.E: What can you tell us about market trends?

C.K: Automatisation with robots/cobots and energy reduction.

E.E: What are the most innovative products marketed?

C.K: Cryogenic blast deflashing machines with patented media-blasting angle adjustment.

E.E: What estimations do you have for 2022?

C.K: Hard time regarding cost development of sub suppliers parts and availability of electronic parts. Good customer relationships help AW to get stable in the market of cryogenic deflashing machines.