Bal Seal Engineering is a designer and manufacturer of custom seals, springs, and contacts for critical equipment used everywhere – from deep sea to deep space. The components we make help designers achieve breakthrough performance and gain a competitive edge.

Easy Engineering: What are the main areas of activity of the company?

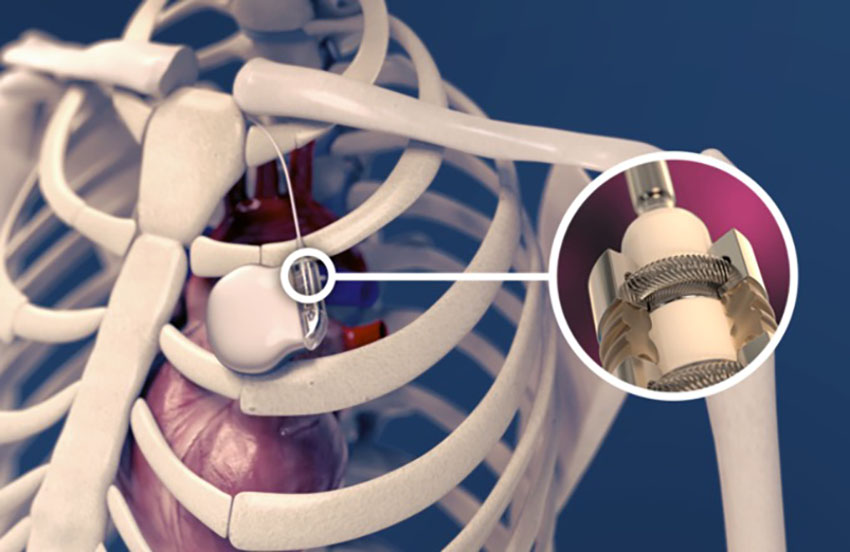

Bal Seal Engineering: Because most people understand the critical nature of cardiac health management and neuromodulation, these are areas where our products are probably most well-known and visible. Our Bal Conn® electrical contact, which facilitates transmission of current from the battery and electronics to the lead in active medical implantables, has built a reputation for unmatched reliability. The Bal Conn is currently at work in more than a million devices worldwide.

Also, our Bal Seal spring-energized seals are contributing to advances in both industrial and surgical robotics, where a balance of low-friction and sealing effectiveness is important for accuracy and consistency.

In addition, we’ve been solving aerospace challenges since our beginnings in the late 50’s. Notable recent successes in this industry are the Mars 2020 Perseverance rover and the Ingenuity Mars copter.

We also have a strong track record in energy, where our seals and springs prolong the life and safety of equipment used in demanding oil, gas, and power transmission service.

E.E: What’s the news for 2021 about new products?

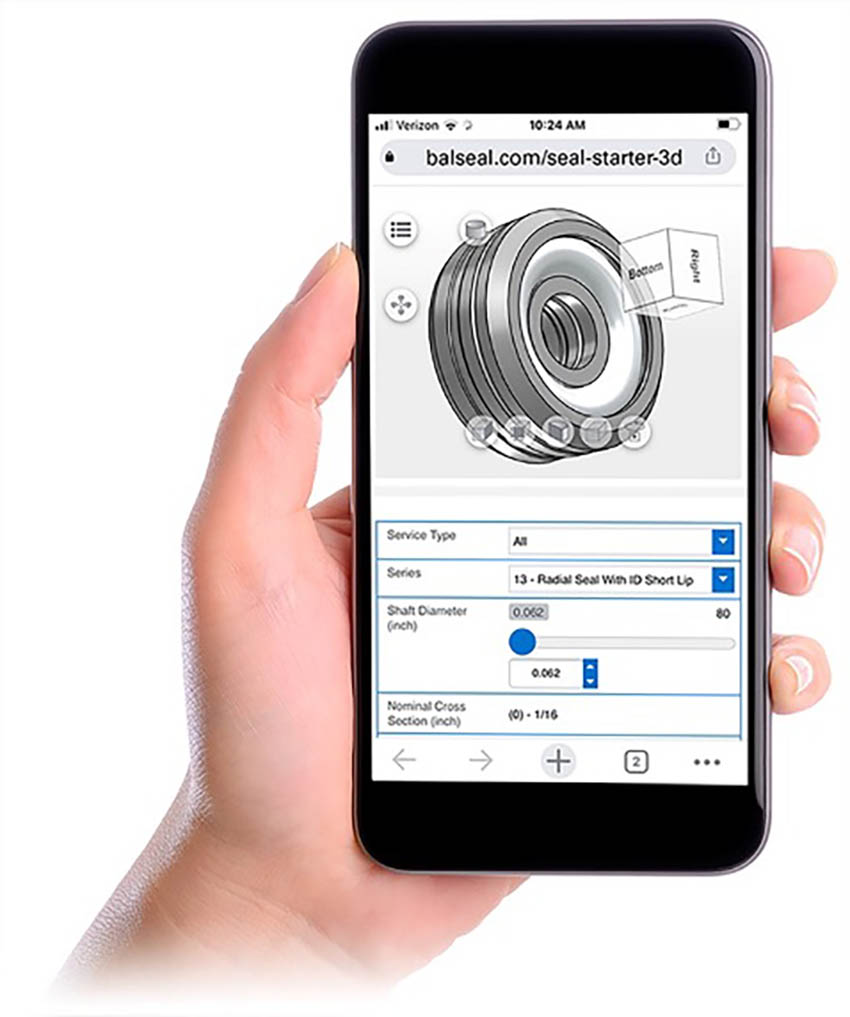

Bal Seal Engineering: Our biggest news of 2021 isn’t about products at all. It’s about a tool that makes it easier for designers to experience the benefits of custom sealing. Seal Starter 3D™ is a configuration platform that contains a selection of our most popular Bal Seal® spring-energized seals for rotary, reciprocating, and static service. In its virtual CAD environment, users can choose a seal series and begin customizing it within seconds to meet specific requirements for size, temperature and media resistance, pressure, and speed.

Based on hardware-related input, Seal Starter 3D’s built-in logic offers seal jacket material recommendations that include virgin and filled polytetrafluoroethylene (PTFE) and polyethylene (UHMWPE), poly ether ether ketone (PEEK), and other premium polymers. A visual toolbox enables users to change viewing angles, rotate a seal concept 360 degrees, and even examine its geometry in cross-section.

We built Seal Starter 3D for the busy engineer who wants to pre-qualify a sealing solution before engaging in deeper conversations, trading emails, or making phone calls. The tool is available 24/7, and it’s mobile-friendly. It requires no special software or plug-ins, and seal concepts can be created in U.S. Imperial or metric dimensions.

Seal Starter 3D is a free resource, accessible on the Bal Seal Engineering website here.

E.E: What are the ranges of products?

Bal Seal Engineering: At Bal Seal Engineering, we offer three core product types: Bal Seal®, Bal Spring®, and Bal Contact®.

The custom-engineered Bal Seal® spring-energized seal sets new standards for performance and reliability in rotary, reciprocating, oscillating, and static/face service. Precision machined from PTFE and other premium polymers, our seal employs innovative geometries and wear-reducing canted coil spring energizer technology to extend the service life of critical equipment. With nearly limitless combinations of jacket and spring materials to choose from, the Bal Seal gives designers the ability to closely control frictional forces and optimize sealing effectiveness in a broad range of chemicals, temperatures, and pressures. Bal Seal locking ring designs and backup elements can help push performance levels even higher.

Our versatile Bal Spring® canted coil spring is a proven solution for mechanical connecting, electrical conducting, and EMI/RFI shielding challenges. Its size, simplicity, and multifunction capabilities can help you reduce system complexity and weight while improving functionality.

The Bal Contact® electrical contact helps designers connect with confidence. That’s because our compact, efficient contact manages high, medium, and low current with unmatched reliability, dramatically improving equipment performance and reducing costly downtime.

The contact’s spring element, with its individual coils, compensates for misalignment and surface irregularities, delivering superior multi-point contact and conductivity with minimal heat rise – even in high shock and vibration.

E.E: At what stage is the market where you are currently active?

Bal Seal Engineering: Some of the markets we serve, such as energy and analytical equipment, can be considered very mature. For example, we began working with liquid chromatography equipment OEMs back in the 1980s to help seal the extreme pressures in that field of science. The same goes for energy, where our products protect downhole tools used in oil exploration and drilling. But the interesting thing is that we’re constantly challenged to help meet new demands. Our role is part consultative engineering, part component manufacturer, so we get to see and work on new challenges, even in mature markets.

E.E: What can you tell us about market trends?

In medical electronics, designers are being challenged to make smaller, more functional devices. Demand for miniaturization is coming from both surgeons and patients, so everything in a device must deliver optimal performance while conserving precious real estate.

In surgical and industrial robotics, engineers are carefully choosing components, like seals, that can contribute to accuracy and consistency. They’re looking for materials and designs that strike an ideal balance between friction and sealing effectiveness.

In medical devices and surgical instruments, we’re seeing demand for components that can stand up to repeated sterilization while delivering longer service life. And in power management applications, such as electric vehicle charging, components must have the ability to operate with low heat rise for safe and prolonged operation.

E.E: What are the most innovative products marketed?

Bal Seal Engineering: Since every product we make is custom-engineered, we’re called upon to innovate every day. One day, it might be a new seal geometry that minimizes lip contact and delivers effective sealing at high speeds in a medical hand tool. The next day, it might be a spring design that provides mechanical latching and EMI shielding in a piece of critical military communications equipment. Often, innovation can be found in the application of our springs, seals, and contacts, and not just their design.

For technical or editorial information, contact

Mark Halloran

Marketing Director

Bal Seal Engineering

19650 Pauling

Foothill Ranch, CA 92610

For sales inquiries, contact:

In Europe:

Bal Seal Engineering Europe BV

VIDA Building, 1st Floor

Kabelweg 57

1014 BA Amsterdam, The Netherlands

Phone: +31 20 638 6523

FAX: +31 20 625 6018

Email: ordersbv@balseal.nl

In the U.S.:

Bal Seal Engineering

19650 Pauling

Foothill Ranch, CA 92610

T: 949.460.2100

F: 949.460.2300

Email: sales@balseal.com