BalestrieriMac is an Italian manufacturing company born from passion about mechanics, handed down from father to son. It is active on the national and international markets for more than 40 years in the woodworking machinery sector and, since the beginning, specialized on the production of “special” machines.

In their work, professionalism, experience, and technical-operational knowledge of the sector, constitute a unique corporate asset that allows them to build machines and/or plants able to solve at best production problems related to wood and PVC processing.

Easy Engineering: What are the main areas of activity of the company?

BalestrieriMac: It is a company specialized in study, development, realization and customization of machinery and / or plants for woodworking (doors, windows, frames, doors, coffins, turned / shaped, edges / solid woods for MDF and Chipboard) and PVC (cutting, drilling and milling) upon specific request or particular need.

It is also specialized in cutting – drilling – welding (using traditional machinery) of iron and iron alloys (primarily construction steels) but also copper, brass and zinc such as to obtain finished metal products ready for use in the industrial field. “

E.E: What’s the news for 2020 about new products?

BalestrieriMac: The machines we produce have always been built with first choice Italian materials, a real 100% made in Italy, which guarantee maximum robustness, quality, durability and precision in the processing of our machinery.

From this year we have given a new image to our products, a new aesthetic but above all latest generation software capable of supporting Industry 4.0 (interconnection between machines and remote control).

This year we have also introduced open houses, within our company, in which it will be possible to “physically touch” our machines, see them on working, receive all the necessary information and an eventual quotation.

E.E: What are the ranges of traded products?

BalestrieriMac: Our range of machine is composed by:

MILLING-ANUBA HINGES MACHINES

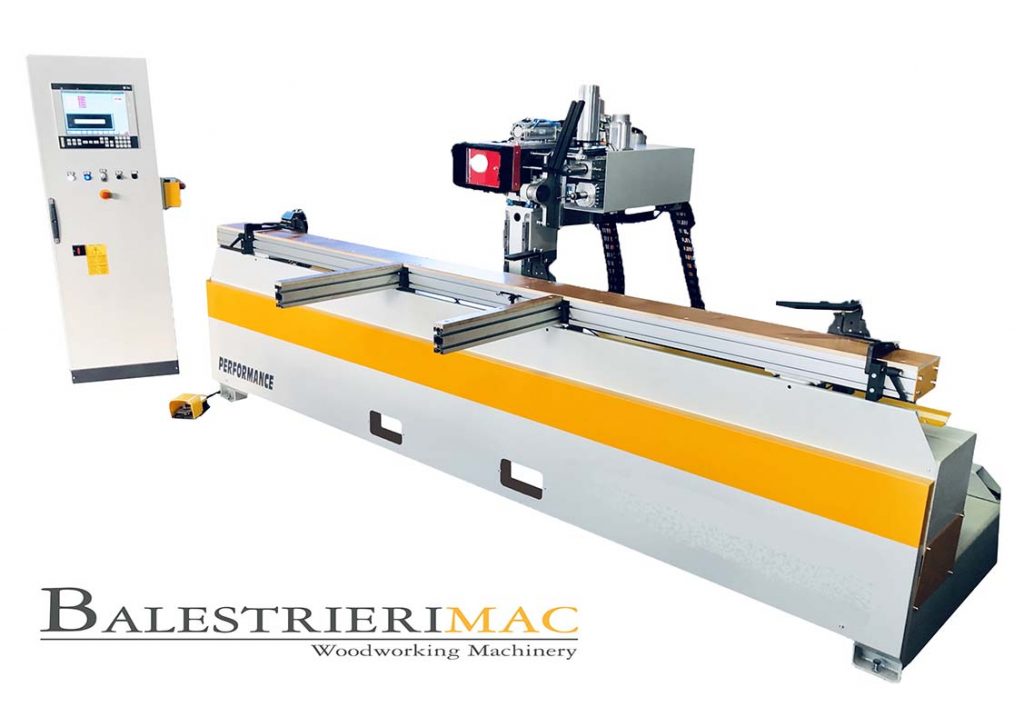

In this category we boast of machinery such as our Performance Plus (CNC 5-axis milling and anubating machine with vertical and horizontal movement) a machine with a high production capacity, designed for the execution of seats for locks on doors or seats for counterplates on frames and, furthermore, various types of slots for shutters and other processes such as knobs – pawls – bolts – Stanley, etc., and in general all the horizontal and vertical millings included in the work area concealed hinge, “pivot” hinge. It also installs and screws ANUBA, normal, baroque or double leg hinges.

Or Machines like our FOLD 2500 (automatic machine for “v” milling, for the cross-folding system (folding system on MDF panels, covered in PVC and various laminates) optimal machine for the production of small furniture, Hi- Fi, especially drawers and other particular uprights with the folding system.

One of our flagships is the TEKNODOOR 3001 PLUS (double cutting with 90° and 45° blades – automatic boring – milling for counterplates – concealed hinges, pivot hinges housing – pre-drilling, introduction and screwing anube) an automatic operating unit for the processing of frames and doors with 45 ° junction. Machine controlled by 6-axis NC.

To conclude, we recall our UNI-DOOR 3000 (double cutting with radial cutting system and 45° tilting blades – automatic lateral drilling – milling for counter-plate, hinges, housing – pre drilling, introduction and screwing anube) automatic unit for the complete working of frames and doors.

CUTTING AND MILLING MACHINES

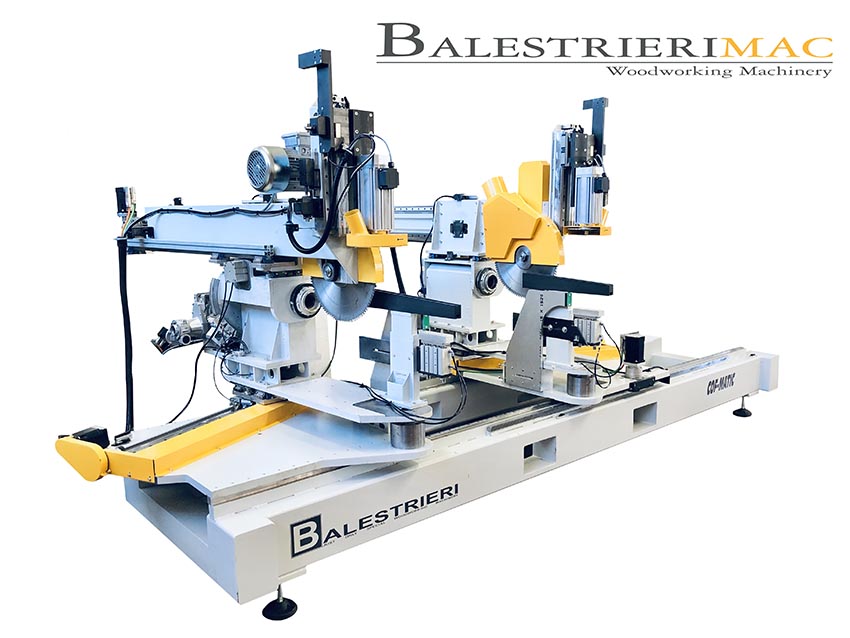

In this category we should find very special, if not unique, machines such as the COF-MATIC (automatic double cutting / milling machine with double inclination blade units – rotating and tilting blade / milling units) particularly designed and built for the processing of coffins.

Or machines, such as TECHNA 3001 PLUS (automatic double cutting machine – radial cutting system – boring units – head rotation at 45°) solid wood or MDF covered with laminate, veneer etc.

Then we have machines like the SMART 45 (an automatic double cutting machine with boring units and blade inclination) conceived strictly for the processing of the door frame with a 45 ° junction.

LATHES

Including the MATIC 120 / 4A (automatic vertical copy lathe with oleo-pneumatic controls) and the MECC 120/4 (Mechanical Vertical Copy Lathe).

PRESS

Our press, PRESMATIC, is an automatic press for straight and curved solid wood edges (electric system – with 2 shelves).

SEZIONATRICI

And our panel saw, the GALAXY (automatic electrotechnical panel saw) for curved panels.

E.E: At what stage is the market where you are currently active?

BalestrieriMac: Waiting for a better assessment of the effects that the health emergency will have on the economy of the sector, the Italian sector of woodworking machines and tools would have achieved a decrease of about 10% in 2019 compared to the previous year. A particular negative trend was recorded on the markets of Russia and Turkey. Also noteworthy is the percentage-significant result indicated for Brazil, a market that would return to growth by increasing its “made in Italy” purchases by 30%.

E.E: What can you tell us about market trends?

BalestrieriMac: As far as we are concerned, in 2019 we did not experience significant drops, as previously mentioned, and in 2020 our market is growing despite the COVID emergency, distinguishing ourselves from the national and international market trend and we are enormously satisfied about this.

Our growing was towed by national (Italian) market, in particular thanks to Southern Italy and by Eastern-Europe countries (such as Romania, Bulgaria and Poland)

E.E: What are the most innovative products marketed?

BalestrieriMac: Regarding the most innovative products on the market, it is important to consider the transition from traditional machines to automatic machines, up to integrated systems.

The challenge is to create Machinery more and more capable of exploiting the most innovative technologies and capable to guarantee a higher level of quality and benefits in terms of time saving. This is the work we do here at BALESTRIERIMAC.

E.E: What estimations do you have for 2020?

BalestrieriMac: In 2021, exports will undoubtedly resume enjoying a slightly brighter potential foreign demand which will allow for a new increase in sales on foreign markets, but still very moderate.

After the Covid emergency, world trade is expected to start growing again in 2021. The fastest growing region will continue to be Middle-East.

BALESTRIERIMAC will continue to be focused on Europe and, more specifically, on Eastern Europe Countries, according to the fact that its Machines features are particularly adapted to these markets.