BANDO is one of the global market leaders in the manufacture of drive belts. The company has been producing timing belts and V-belts with more than 4,000 employees at 19 locations worldwide since 1906. BANDO has been in Europe for over 40 years with two sales and distribution centers and one production facility. They also have their own development department and are in constant contact with customers in order to develop solutions together.

Interview with Peter Schreiber Romero, Sales and Marketing Manager of BANDO Europe.

Easy Engineering: What are the main areas of activity of the company?

Peter Schreiber Romero: We specialize in the development of drive solutions for precision applications such as medical technology, 3D printers, security cameras, ATMs. So, wherever a high degree of precision, durability and low noise is required.

Furthermore, our portfolio includes products for extreme applications such as wood or stone shredders or high-speed applications such as CNC machines.

E.E: What’s the news for 2021 about new products?

P.S.R: With electric mobility, the need for low-noise components has increased due to the lack of engine noise. Our R&D department, based in Germany, has developed belts called EPS belt for zero-noise power steering together with our Japanese colleagues for a well-known German component manufacturer, which are now installed in most electric vehicles of all well-known manufacturers worldwide.

E.E: What are the ranges of products?

P.S.R: Our product range includes a large number of products from timing belts made of rubber to polyurethane with steel tension cord, aramid or fiberglass. As well as classic V-belts, Scrum V-belts, Poly-V belts, etc. with different tension cords and performances. But what really sets us apart is the depth of our range, which means we have a very large selection of available lengths. So, the right belt for all applications.

E.E: At what stage is the market where you are currently active?

P.S.R: The market is changing rapidly due to the pandemic as the supply chains have collapsed massively in some areas. If it was previously necessary to buy as cheap as possible worldwide, the focus is increasingly relying on manufacturers who produce high-quality products, have well-thought-out logistics and constant availability. The optimization of the delivery processes has always been practiced at BANDO as a Japanese manufacturer and our customers were able to benefit from this, especially during this time.

E.E: What can you tell us about market trends?

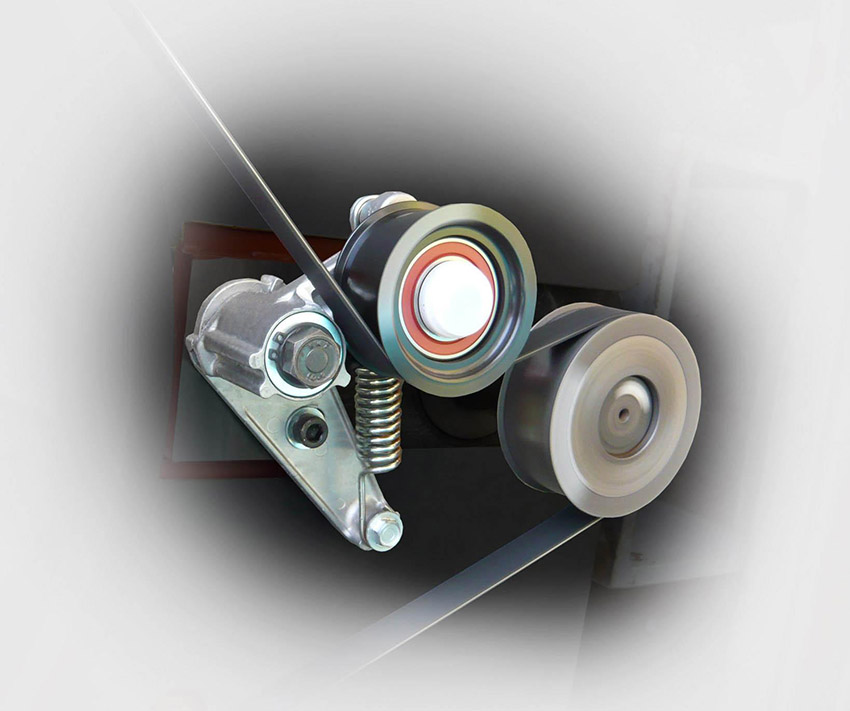

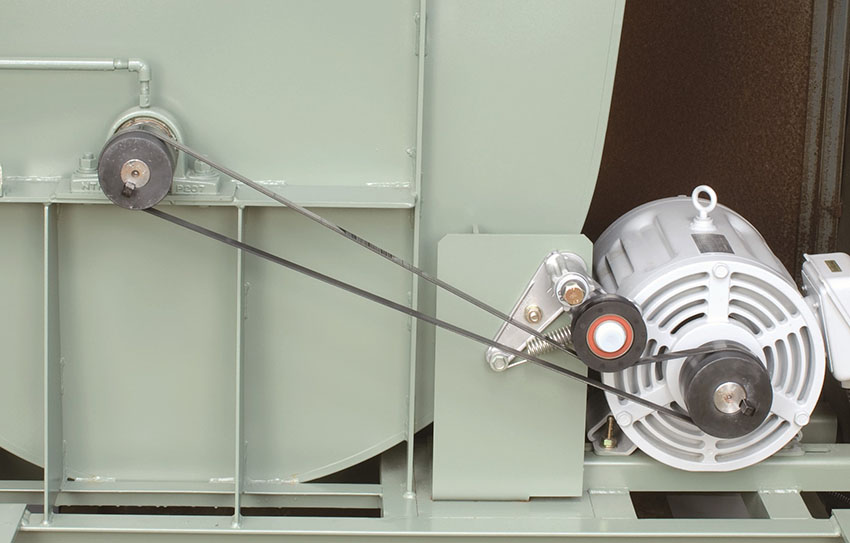

P.S.R: Due to climate change, efforts to reduce CO² emissions, save energy and resources are the aim of every corporate climate policy strategy. Many systems that are still fully functioning are replaced at high cost and unnecessarily. BANDO has dealt with this important topic and as a result developed the HFD – System ™ (Hyper Flat Belt System).

The system includes an EPDM flat belt that is automatically centered on the pulleys and does not require any further maintenance due to the special tensioner. This construct avoids a considerable amount of frictional losses through, for example, a much larger angle of wrap. Even the latest “energy saving V-belts” on the market cannot achieve these results.

E.E: What are the most innovative products marketed?

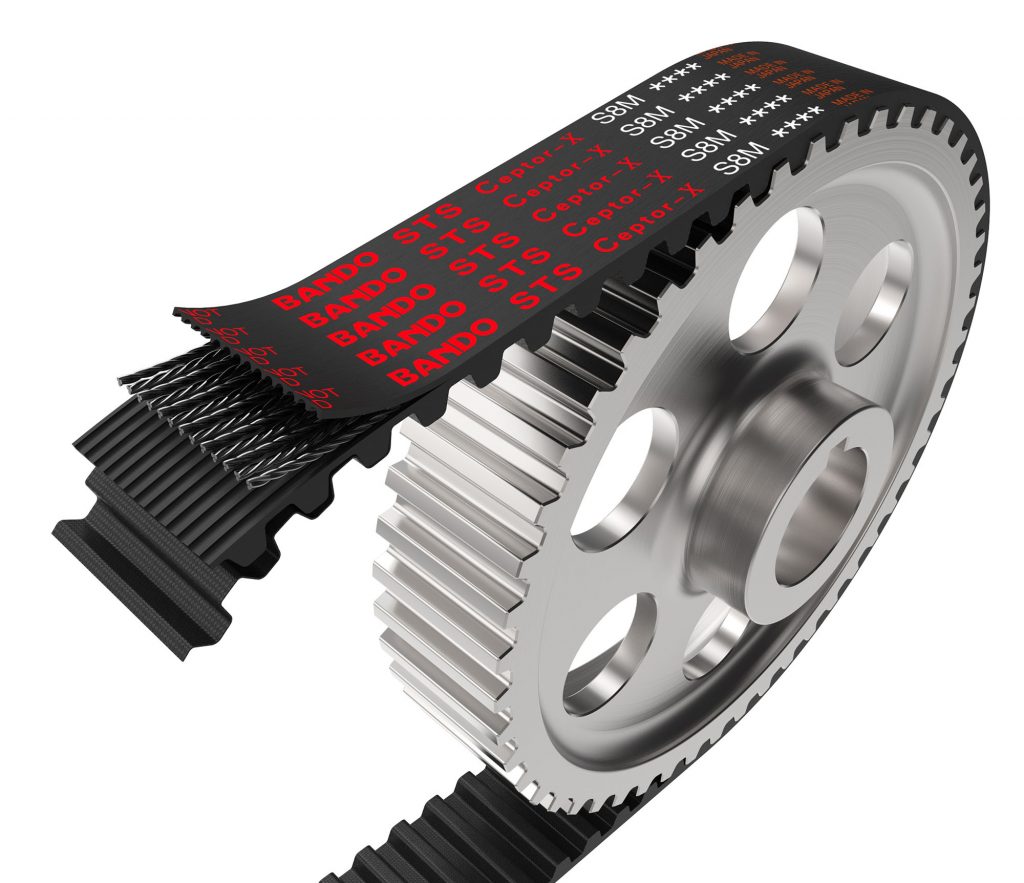

P.S.R: As in the examples already listed, BANDO develops and deals with a lot and is always an innovation driver for the various customer or market requirements. The need for products that have to mobilize enormous forces and at the same time are allowed to take up less and less space is growing steadily.

The Ceptor®X belt is a timing belt with reinforced HNBR rubber compound and the OEM proven STS profile. The tension cord made of CARBON and enables a further improvement in performance compared to the high-performance products. Most carbon tensile cord products on the market are made of a PU material and are extremely sensitive to noise at high revolutions. Especially in the age in which production plants have to achieve a health-promoting work atmosphere, noisy plants are counterproductive.

E.E: What are your estimations for the rest of the year??

P.S.R: Developing solutions together with our valued customers, especially in the challenging times, in order to master the challenges and grow together. Anyone looking for quality, additional value and excellent service will find it at BANDO.

Premium Quality Power Transmission – since 1906 –

BANDO EUROPE GMBH

Krefelder Str. 671 · D-41066 Moenchengladbach

Tel.: +49 2161 901 04 0

Fax: +49 2161 901 04 50

Website: https://www.bando.de

Email: info@bando.de