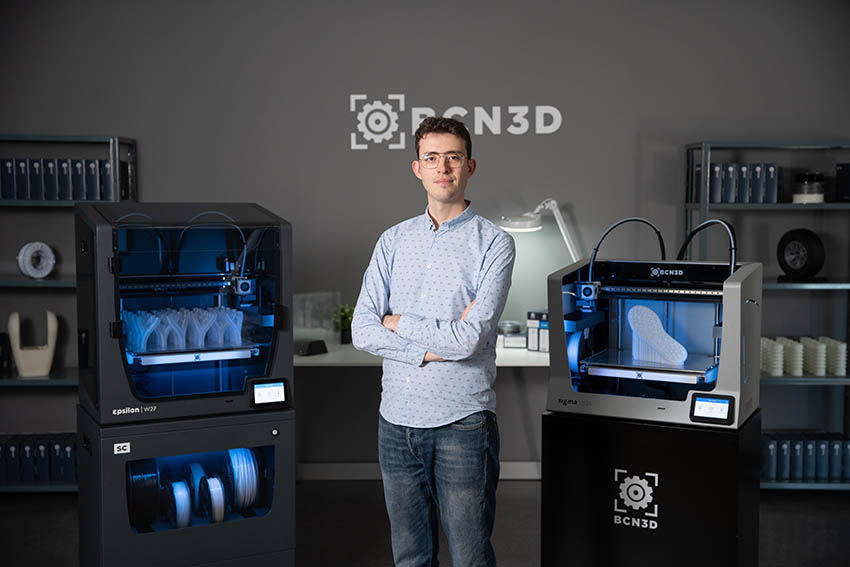

Based in Barcelona, BCN3D is one of the leading developers and manufacturers of 3D printing solutions in the world. They firmly believe in delivering the best quality tools to both professionals and industry level users. Above all, the company’s goal is to enable creators and innovators to materialize their ideas by providing a platform for creation. Some of their clients include Nissan, BMW, NASA, Camper, Louis Vuitton and the Massachusetts Institute of Technology (MIT). Design that enables design; at BCN3D, we are meticulous.

Interview with Eric Pallarés, CTO at BCN3D.

Easy Engineering: A brief description of the company and its activities.

Eric Pallarés: Our desktop 3D printers are crafted after a long process of design and investigation to ensure that the end result is optimal. From the assembly stages to picking up the phone to assist with any user doubt, we are aiming for the highest quality. We want to give the best tool possible to those who are going to change how things are made in the future. Co-creating and co-innovating with them is a must at BCN3D; this is why we want to be part of the processes and build relations to continue being enablers in many different industry fields. We work for combining our expertise with groundbreaking ideas to create change. We began as a division of the CIM-UPC, a non-profit organization for the advancement of technology and a leader in additive manufacturing. Through the Open Source RepRap project under the name RepRapBCN, we specialized in FFF (Fused Filament Fabrication) technology and investigated and released RepRap printers from 2012-2014 to get us started in the 3D printing industry.

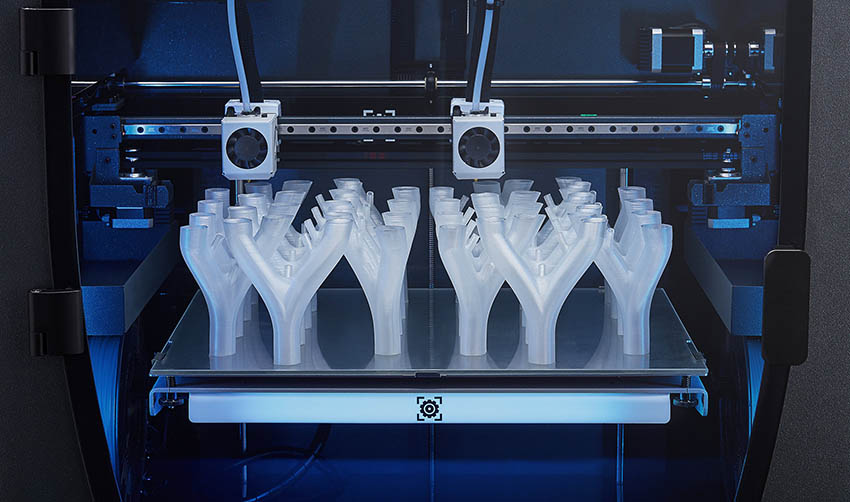

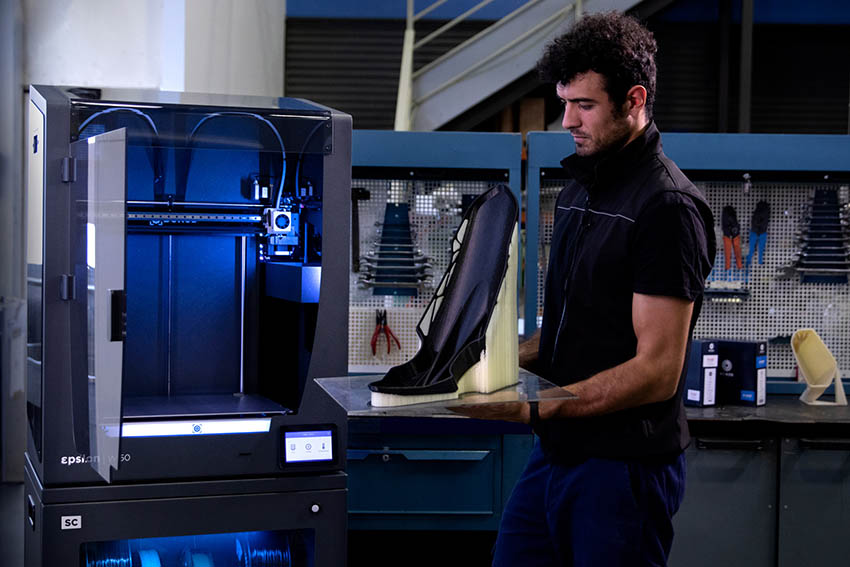

In September 2020, we launched the BCN3D Epsilon and Sigma series, featuring brand new state-of-the-art 3D printers together with the Smart Cabinet for optimum filament storage. In our commitment to providing the best ecosystem across both hardware and software, we acquired AstroPrint: a 3D printing software company known for its sophisticated cloud solutions. Next to that, we also released BCN3D Stratos, a new updated version of our slicer and the brand new BCN3D Cloud. In 2022 We announced Viscous Lithography Manufacturing (VLM)™: a never-before-seen resin-based 3D printing technology that unlocks manufacturing autonomy. Our VLM Technology Adoption Program allows companies across all industries to test the breakthrough technology out for themselves.

E.E: What are the main areas of activity of the company?

E.P: Hardware, software, production of 3D printers and create a support team and a specific engineer team to innovate new products. We are giving 3D printing professional solutions for those sectors: automotive, aerospace, product design, manufacturing, tooling and engineering.

E.E: What’s the news about new products?

E.P: VLM is the recent new 3D printing technology. Our VLM Technology Adoption Program allows companies across all industries to test the breakthrough technology out for themselves. We created and Adoption Program to invite the worldwide companies to know more about VLM 3D printing technology with high viscosity resins. In FFF, we introduced since November 2021 a new Metal Pack (1.000 euros) to incorporate metal filament 100% steel in our Epsilon series 3D printers (W50 and W27).

E.E: What are the ranges of products?

E.P: Epsilon series (W50 and W27 and the Smart Cabinet for each one) 3D printers for industrial and professionals and Sigma D25 (desktop series)

E.E: At what stage is the market where you are currently active?

E.P: In constant growth and within the professional sector demand 3D printing solutions at an affordable price (our machines are under 10,000 euros) and with high performance and very reliable that our 3D printers of the Epsilon series can incorporate filaments with very technical materials such as nylon and carbon fiber, among others.

E.E: What can you tell us about market trends?

E.P: We at BCN3D have detected that the main trends in the sector, in our professional range, are that companies using machines with FFF technology are increasingly efficient and facilitate the autonomy of 3D printing within industrial facilities. Our products respond to these needs.

E.E: What are the most innovative products marketed?

E.P: BCN3D Metal Pack launched in 2021. Our Smart Cabinet too and new series Epsilon of 3D printers W27 and W50.

E.E: What estimations do you have for 2022?

E.P: A year full of new innovations for all of our clients in FFF technology and worldwide sector interested by our new 3D printing technology VLM.