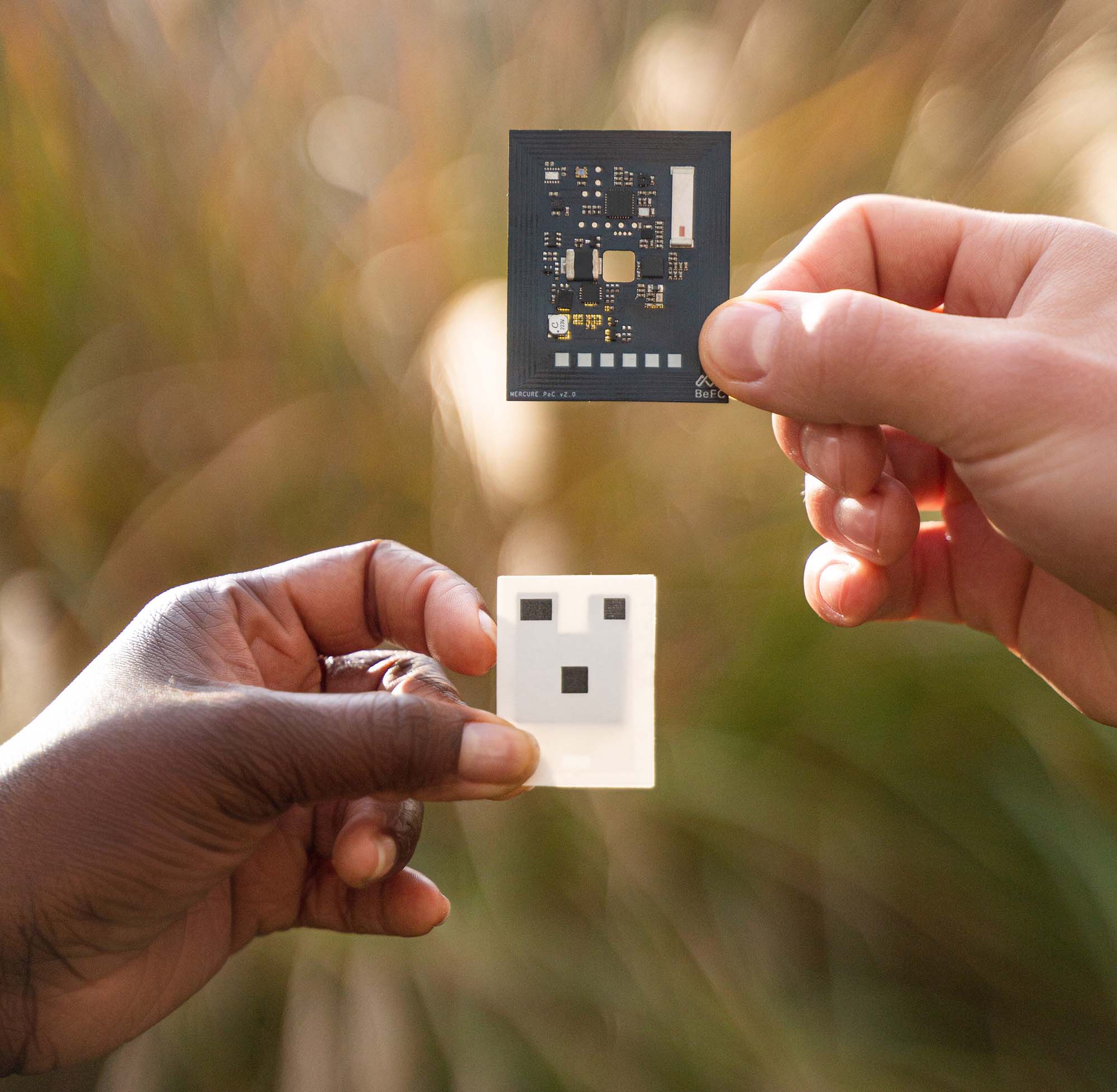

BeFC produce paper-based biofuel cells that use enzymes to convert glucose and oxygen into electricity; an organic energy solution, empowering the next generation of smart and sustainable electronics.

Founded in 2020 as a spinoff from Université Grenoble Alpes in France, BeFC is built from decades of pioneering research. Notably, the group were the first in the world to implant biofuel cells into mammals. The original concept: to power pacemakers and insulin pumps using glucose and oxygen from the bloodstream.

Interview with Dr Jules Hammond, Co-Founder & CEO of BeFC.

Easy Engineering: What are the main areas of activity of the company?

Jules Hammond: The company has pivoted towards low-power electronics in the fields of logistics, smart packaging, single-use medical devices, health wearables, and industrial IoT applications.

Combining their paper biofuel cell with printed electronics, the company provides data opportunities without the downsides of battery disposal.

E.E: What’s the news about new products?

J.H: BeFC has just announced their ecological Active Sensor Tag. The tag can be customised with a range of sensors including temperature, relative humidity, pressure, light, and a 6-axis accelerometer. Measurement frequency and thresholding is pre-programmed depending on the intended use case, but can also be adjusted via NFC.

Optimized to provide minimal component count and a reduced bill of materials (BOM), the tag is a further step towards delivering on the company mission of low-cost and low-environmental-impact. The tag can be easily reused by replacing the BeFC and attaching with its integrated anisotropic conductive film (ACF).

E.E: What are the ranges of products?

J.H: The product range can be segmented into three tiers, defined by the complexity of wireless communication protocol. These include: 1) NFC/RFID, 2) BLE, and 3) the sub-GHz pair,Sigfox / LoRaWAN.

E.E: At what stage is the market where you are currently active?

J.H: The markets are definitely in their infancy. To change the status-quo of traditional miniature coin- or button-cell batteries will take time. With the reduced power and energy densities (in the units of mW and mWh per cm2) when compared to existing technologies, it requires courage and, at least today, compromise to adopt our biofuel cell technology.

Dr Jules Hammond, Co-Founder & CEO of BeFC

Nevertheless, early adopters and pioneers are looking to exploit the organic (and therefore compostable) nature of our technology. In parallel to scaling up our production, we are currently performing more and more complex closed-loop trials with our early clients in order to ensure we deliver products that meet expectations.

E.E: What can you tell us about market trends?

J.H: There are two relevant trends we have observed. The first is towards traceability and transparency. The goal being to provide quasi-continuous monitoring of assets.

The second is that of thin and flexible electronics; particularly through the use of printed technologies. Such a form factor makes it easy to integrate as wearables, or within packaging.

E.E: What are the most innovative products marketed?

J.H: Our talented team have focused on improving manufacturing scalability whilst simultaneously reducing cost. This has primarily been achieved by transitioning to a printed biofuel cell technology, but also by taking advantage of high-volume and industrial integrated circuits (ICs) including system on a chip (SoC) and system in package (SiP) solutions.

E.E: What estimations do you have for the rest of 2022?

J.H: We’ll see much more data collected in the effort to gain insights to how we can improve efficiencies. In turn, we’ll see a push towards edge computing; designed to reduce energy consumption from data transmission and storage in applications where it may not be necessary.