Berkoa Machine Tools is a cooperative based in Elgoibar, a town in the heart of the Basque Country with a strong tradition in the machine tool industry. Berkoa S.Coop. came into being seven years ago as a response from some of the workers to the closure of a previous company. It brought together a perfectly balanced team made up of professionals with extensive experience in the field of machine tools, in addition to Berkoa’s strong commitment to the new generations of highly qualified young people. This combination in the team has allowed them to fulfil their values: innovation, dedication and enthusiasm.

The company’s main activity, design and manufacture of new special machine tools, has the motto “You name it, we make it” very much in mind, offering services that meet the specific needs of customers.

Interview with Andoni Garcia-Abad Etxeberria, General Manager at Berkoa Machine Tools.

Easy Engineering: What are the main areas of activity of the company?

Andoni Garcia-Abad Etxeberria: The company’s main areas of activity cover various sectors, the manufacture of new machine tools, machine retrofitting, Technical Assistance Services (T.A.S.), the sale of second-hand machines, the subcontracting of SoldAvanza (Rotary Friction Welding) and the option of participating in specialised welding courses and seminars.

E.E: What’s the news about new products?

A.G.A.E: As new products we can highlight our IkasMak 5.1 project, a multi-process machine designed for vocational training centres. This machine has the singularity of bringing together the characteristics of several machines in one. The most notable milestone with this project is the tender obtained by the Basque Government for the manufacture of 13 multiprocess machines for the vocational training centres in the region, which are already fully operational for this academic year.

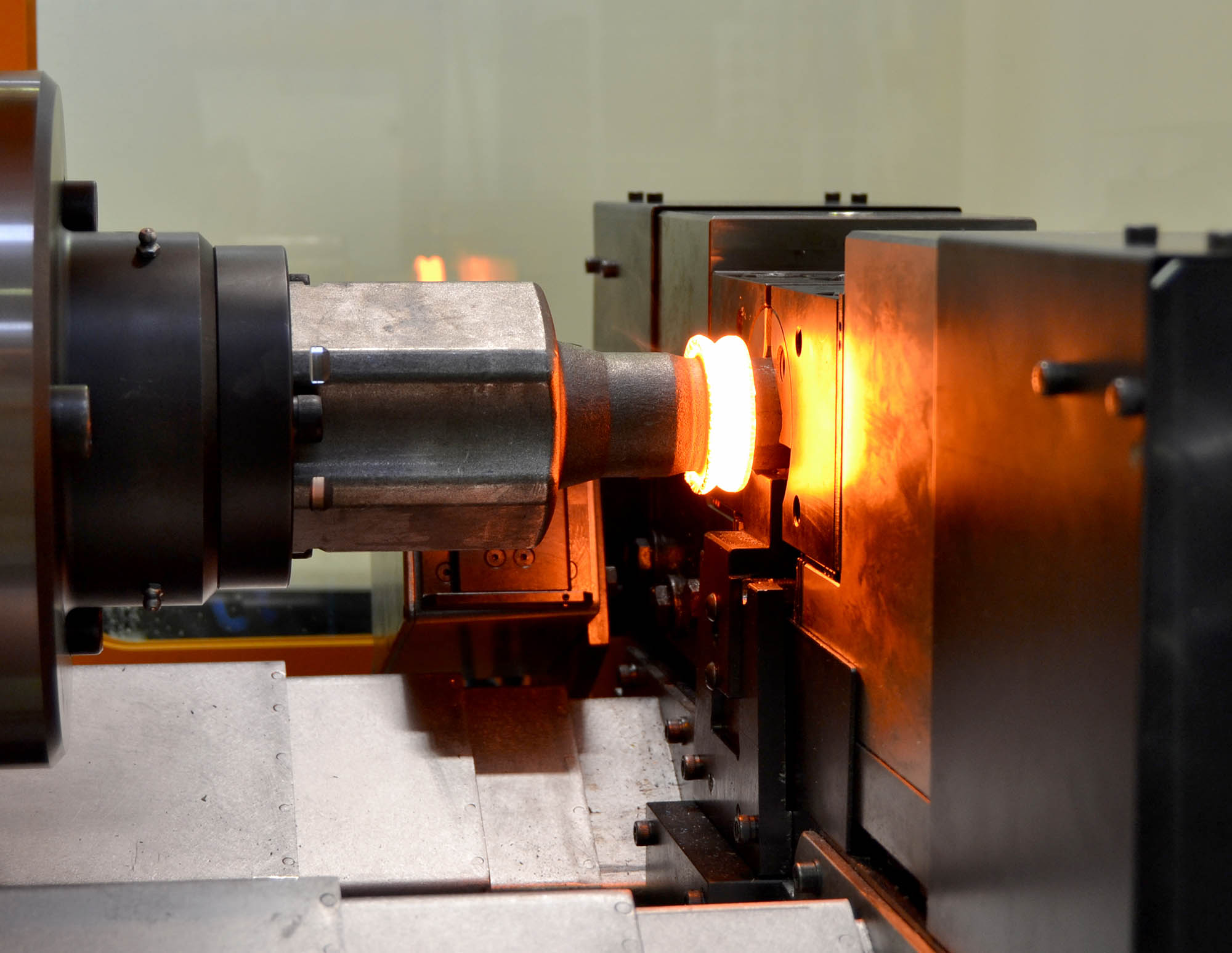

Another of our new products is the manufacture of the advanced welding machine called SoldAvanza. The machine that is in our facilities has allowed us to open a new line of business such as subcontracting for manufacturing, prototyping and testing.

The unique feature of this machine is the registered controller © BLSC 4.0, designed together with the Lortek technology centre, which allows traceability and storage of the characteristic parameters. This welding machine allows customers to experiment with new joining solutions and to validate their designs before moving to full-scale production, providing companies with access to advanced and unique technology without the need for significant upfront investment.

E.E: At what stage is the market where you are currently active?

A.G.A.E: As mentioned above, our main activity is the design and manufacture of turnkey special machines, always adapting to the customer’s needs. In this way, the markets in which we are involved are various; automotive, agricultural, petrochemical, capital goods, education. However, requests for supply also come from other markets such as railway and wind power.

E.E: What can you tell us about market trends?

A.G.A.E: The current market trend that we are being asked to address is strongly focused on the circular economy, and in our case, it focuses on carrying out what we call “retrofit” or “retrofitting” of machines. The basic purpose of retrofitting is to use used or scrap machine components and refurbish them. This practice is aimed at extending the useful life of industrial equipment and mitigating waste.

In essence, machine retrofitting is aligned with the premise of converting existing industrial equipment into more sustainable and efficient solutions, while significantly reducing waste generation. The initiative translates into a comprehensive strategy to optimise machine performance, thus contributing to resource preservation and responsible resource management.

E.E: What are the most innovative products marketed?

A.G.A.E: Apart from the IkasMak and SoldAvanza project, mentioned above, we have manufactured several machines of these models. It is also worth mentioning the manufacture of several TD2-800 and TD2-1000 vertical lathes designed for turning discs for tilling soil and sowing, for Bellota Agrisolutions & Tools in the USA.