Besseling Group manufactures equipment for extending the storage life of fruits and vegetables. The company does this by bringing down the oxygen level in a storage cell to the optimal minimum, and rising the CO2 level to the optimal maximum. Some fruits also produce Ethylene which need to be removed in order to keep the fruit fresh. Furthermore, Besseling offers all related products needed to install- and connect the machines to a storage cell.

Easy Engineering: What are the main areas of activity of the company?

BESSELING: We are mainly active in the fruit storage industry, of which most of it considers apple- and pear storage. But besides that, we also have experience in storage applications of onions, garlic, cabbage, kiwis, pomegranates, bananas, oranges and flowers.

Ancillary activities that we perform are disinfestation of tobacco, cacao, grains, blanketing of several applications and CATT (Controlled Atmosphere Temperature Treatment) of flower bulbs.

E.E: What’s the news about new products?

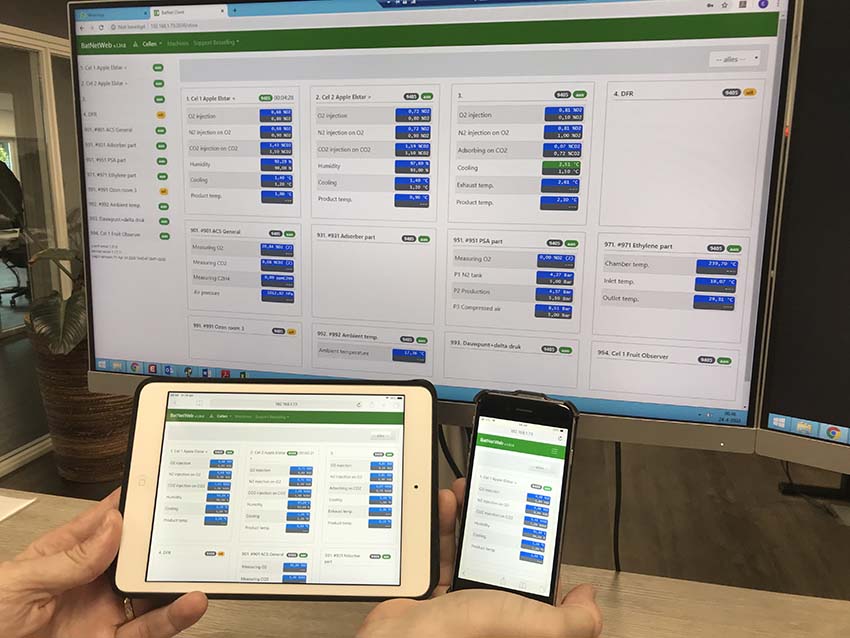

BESSELING: All products are run by our own developed measurement and control technology. This can for example easily be expanded with the addition of a cooling module to arrange all cooling- or humidity related facets. This means the system is capable of controlling the entire cold storage facility. Newest development in this system is a web-based version which allows users to follow their products easily on a remote device, like a smartphone or tablet.

E.E: What are the ranges of products?

BESSELING: Our main products are the CO2 Adsorber to take the CO2 out of the storage cell which is produced by the product, the PSA Nitrogen Generator to bring down the Oxygen level (by injecting nitrogen), the Ethylene Converter to remove the harmful ethylene gas, and all store protection- and connections accessories like under- and overpressure valves, buffer lungs and special gas-tight flanges.

E.E: At what stage is the market where you are currently active?

BESSELING: The main goal of the fruit storage industry is to keep the fruit in the best possible condition for as long as possible. This means we are continuously looking for ways to improve our products which suit the latest requirements of the market. This means also optimizing all machines, which has led to Besseling having the most efficient machines on the market.

E.E: What can you tell us about market trends?

BESSELING: More and more the limits are searched in order to storage the product as long as possible. If you go too far, this can cause damage to the product. Nowadays new methods are developed to search for the absolute limits, but in a safe way; Dynamic Controlled Atmosphere.

E.E: What are the most innovative products marketed?

BESSELING: Besseling has developed the DCA – Fruit Observer™ System, which provides continuous information about the physiological condition of the observed product. By monitoring the chlorophyll fluorescence, we are able to react adequately in order to prevent damage to the valuable product. Changes in the chlorophyll can also provide valuable information about the quality of fruits and vegetables and helps getting the best possible price for the product.

Besseling also supplies equipment to system integrators, one of which is currently very innovative: Softripe. This company uses Besseling Controlled Atmosphere, combined with accurate measurement of O2, CO2, Ethylene and sophisticated algorithms to ripen products in a natural way. This delivers extraordinary results.

E.E: What estimations do you have for 2022?

BESSELING: We have seen that despite the COVID-19 developments there still has been an increasing demand for Controlled Atmosphere equipment. Fruit- and vegetable consumption contribute in keeping your body healthy and in good balance. The world population is still growing, so for the near future we expect more storage facilities in order to keep providing people with the all the desired products.