Founded in 1985, family-owned company BIBKO® Umwelt- und Reinigungstechnik GmbH is specialized in developing, manufacturing and selling of recycling machines to regain mineral components from (liquid) ready-mixed concrete and infrastructural waste. BIBKO’s large sales network customers are served worldwide. The company is based in Beilstein, Germany about 50 km north of Stuttgart.

Easy Engineering: What are the main areas of activity of the company?

BIBKO: Organizational the company consists of two business divisions:

Business division 1: Recycling machines for leftover ready-mixed concrete

Business division 2: Recycling machines for infrastructural waste

While the target group of business division 1 includes the ready-mixed concrete, precast and concrete products industry, the target group of business division 2 includes the sewer cleaning, street sweeping and soil drilling industry.

The objectives in both target groups are the same:

- Saving/ reducing of disposal costs = improvement of economic efficiency

- Production of secondary raw material = optimization of environmental protection

- Recycling of waste = compliance with legal requirements

In order to achieve the objectives the recycling process consists of a multiple stage process. In the 1st stage the material is collected and fed into the recycling machine.

In the 2nd stage the material is processed in a wet-mechanical recycling process. A slowly turning helix moves the material through a water bath. Wash paddles and shovels are segregating the material and remove the undesired components <250 µm. Those are carried out of the recycling machine with the process water.

In the concrete, precast and concrete products industry the process water is usually reused straight in the batch process again. In the sewer cleaning, street sweeping and soil drilling industry the process water is either discharged or treated for reuse.

In the 3rd stage the remaining and recycled material in the recycling machine is picked-up by a bucket conveyor, removed from the water bath and discharged onto the screw conveyor. The screw conveyor dewaters the material and transports the material into the material box.

Once the process is completed the regained and recycled material can be reused as well as the process water. Consequently, a closed loop system is established.

E.E: What’s the news about new products?

BIBKO: With more than 35 years on the market the BIBKO® portfolio provides a wide range of recycling machines and add-on equipment. The established modular concept used enables customized concepts and solutions for both target groups. Exemplary some equipment is shown below. Additionally, it is indicated in which business division it is used more often.

Business division 1: Recycling machines for leftover ready-mixed concrete

Dose buffer

The dose buffer represents an alternative to a regular feeding hopper. Here, the leftover ready-mixed concrete is initially buffered and then continuously fed into the recycling machine by a rotating helix. The advantage of such dose buffer is that the time of the emptying process of the trucks is significantly reduced. In addition the quality of the regained material is independent of the feeding speed of the material as feeding and processing takes place in separate machines.

Filter press

In the filter press the process water is treated to remove the contained and undesired components. After the process there is filtered water and a filter cake.

Business division 2: Recycling machines for infrastructural waste

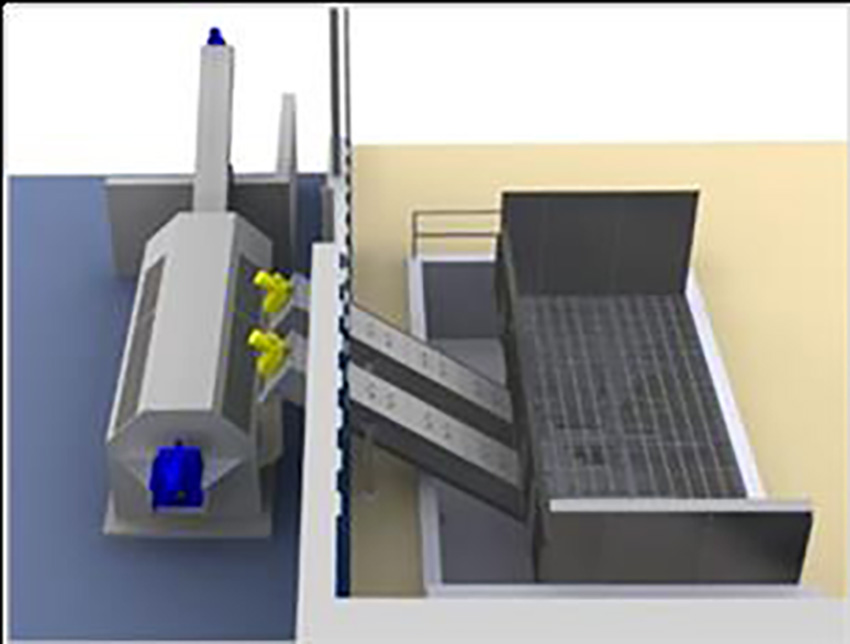

Material bunker

Similar to the dose buffer above the material is initially buffered in the material bunker and then continuously fed into the recycling machine. The difference to the dose buffer is the the design and the larger buffer capacity. While the regular dose buffer can hold up to 5 m³ the material bunker can hold up to 9 m³.

Material bunker (schematically)

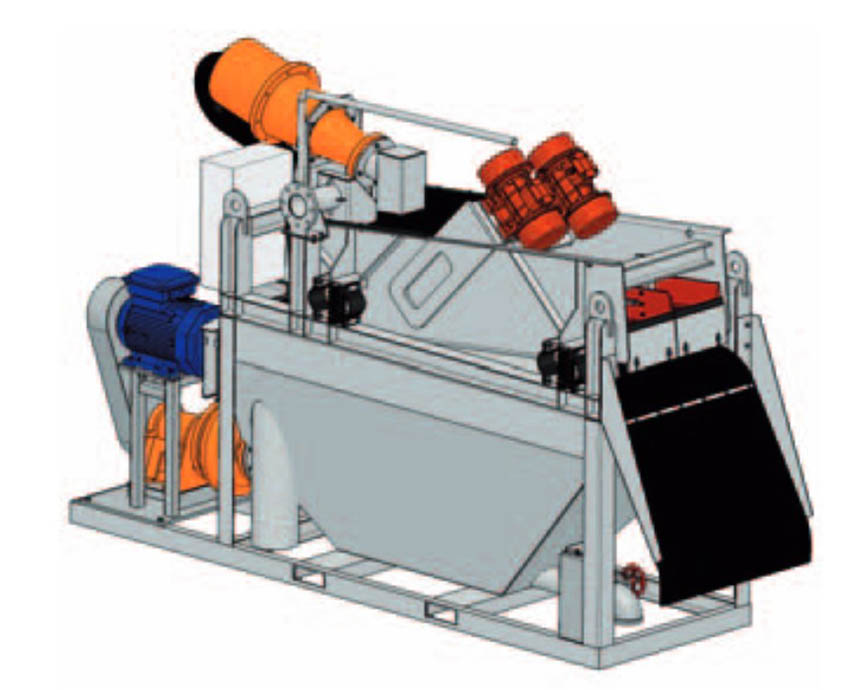

Fine particle separator

With the fine particle separator fines larger than 60 μm can be removed from the process water, dewatered and discharged.

Fine particle separator (schematically)

E.E: What are the ranges of products?

BIBKO: The core product in every project is the recycling machine itself. The BIBKO® recycling machines are available with a mechanical recycling capacity of 4 m³/h, 20 m³/h and 30 m³/h. Based on the quantity of returned and collected material the corresponding recycling machine is selected. In a next step the additionally required components are determined. This ranges from the feeding unit (e.g. hopper, dose-buffer), discharge conveyor (e.g. length from 2 m – 6 m), rinsing equipment, electrical control unit (e.g. plc) up to a full scale water recycling system with filter presses to treat the process water.

E.E: At what stage is the market where you are currently active?

BIBKO: Depending on the business divisions the markets are on different stages. When BIBKO® was founded recycling of leftover ready-mixed concrete was a quite new subject. Hardening and crushing of leftover concrete or discharging into settling pits was state of the art. Legal requirements, limited resources and the sustainability approach changed the mindset. Instead of considering the leftover material as waste it was considered as secondary raw. With this change on the customer side also the supplier side changed. More companies started their business in this growing market and became competitors. Hence, today the market is in a mature stage.

In contrast the market for recycling machines for infrastructural waste is in different stage. State of the art in this field was until recently that large recycling companies processed and recycled the material collected by sewer cleaning, street sweeping and soil drilling companies and a certain fee was charged. Recycling was organized centralized. However, things have changed here as well. Instead of centralized recycling solutions, decentralized solutions are starting to become more popular.

Depending on the quantity of material collected the payback period of such solutions can be quite short. In addition, the dependance from external recycling companies is reduced. The market for such recycling solutions is in a growing stage.

E.E: What can you tell us about market trends?

BIBKO: From our perspective there are three main factors to be successful in the future, too:

Factor 1: Reputation/ name recognition

Excellent Reputation is built on satisfied customers which spread the word. This comes along with extensive marketing activities such as press releases, ads, website and social media platforms on a regular basis.

Factor 2: Experience

The experience of numerous realized projects enables us to work out the best solutions in technical and economic terms for our customers.

Factor 3: Qualified employees

Qualified employees are turning enquiries into offers and projects. In conjunction with the service engineers BIBKO® recycling machines thus provide a solution to the customers problem.

E.E: What are the most innovative products marketed?

BIBKO: As already described above company BIBKO® as well as the related products are well known in the ready-mixed concrete industry. Derived from there the business division 2 – recycling machines for infrastructural waste have been established within the last couple of years. To suit the customers needs in the best possible way the equipment used to recycle leftover ready-mixed concrete has been modified accordingly.

A perfect example are the newly developed recycling machines itself. While in the ready-mixed concrete industry the recycling machines usually are based on a one-chamber washing principle, the recycling machines for infrastructural waste are based on a double-chamber washing principle. The double-chamber washing principle assures the constantly high quality of the washed material but additionally assures that organic content is removed.

First the material enters the pre-wash chamber. In a second stage the material is washed once again in the main-wash chamber. Simultaneously, water (fresh water or filtered water) flows in a counter-current principle from the main-wash chamber into the pre-wash chamber. Consequently, in the main-wash chamber there is always the best water quality to achieve the best recycling quality.

E.E: What estimations do you have for the rest of 2022?

BIBKO: Despite the current world political situation, we expect a good year 2022. We are optimistic that some more orders can be turned in till the end of the year. Especially in business division 2 some larger projects, where a lot preliminary work has already been done, are still expected.