By replacing fossil-based plastic with FibraQ compounds Biofiber Tech help Brand owners reduce their CO2 emissions.

Biofiber Techs patented technology makes wood fibres hydrophobic and more compatible with plastics. Therefore, FibraQ compounds can be used in products where wood-fibre based plastics have not been an option before.

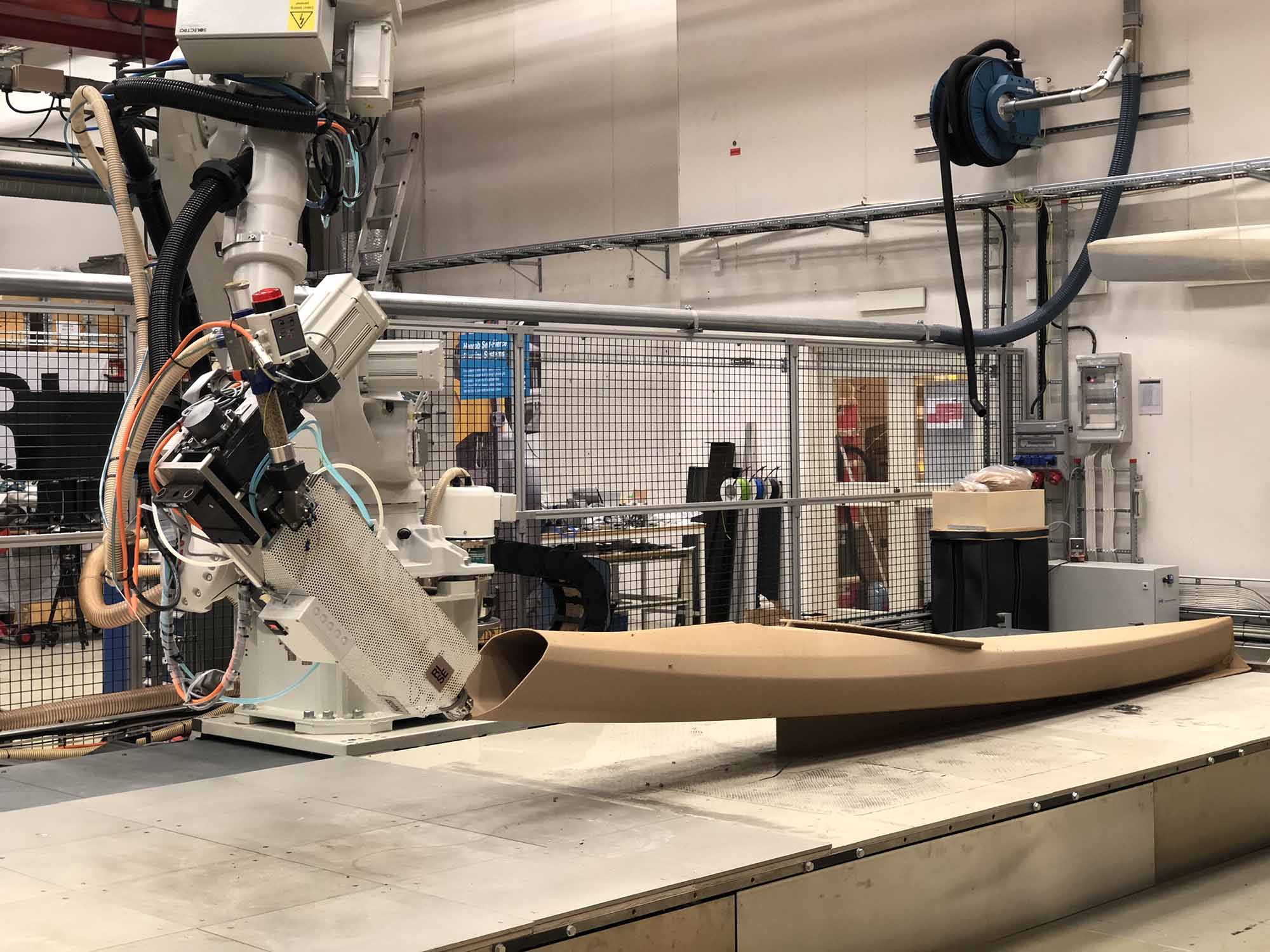

With sustainably managed forests as a resource, they create sustainable materials for long-lasting plastic products. From household products to 3D printed furniture or electronics, to name a few!

The innovation brings the possibility to use wood fibre-based plastics for a large range of products and production methods. From injection and extrusion molding to 3D printing.

FibraQ can be sold to any plastic compounder with a twin-screw extruder, no need for the compounder to be specialized or adopt production from existing. Giving any compounder a chance to create sustainable plastics by offering wood-fibre based plastic.

FibraQ compounds can be sold to Brand owners or manufactures for use in existing tooling and processes where they today use fossil-based plastic like, PP/PE/ABS/TPE etc.

Easy Engineering: What’s the news about new products?

BIOFIBER: During 2022 we further expanded our portfolio of sustainable materials, launching new FibraQ compounds to meet the high interest and demands from different industries.

During 2021 we launched FibraQ and our first FibraQ compounds that was PP and PE based. But since we got so much attention from brand owners and manufactures saw the big potential when hearing about how our innovation differs from traditional wood fibre-based plastics. We set a higher focus on developing compounds that could meet the needs for the automotive and electronics industry, as well as launcher even softer materials like the TPE range.

Since one key benefit with our innovation is that it opens up the use of wood fibres in a wide range of polymer matrixes, it is also beneficial for Brand owners that use different production methods and plastics.

E.E: What are the ranges of products?

BIOFIBER: We offer FibraQ, our wood fibre pellets to Compounders and our FibraQ compounds to Brand owners and their manufactures. https://www.fibra-q.com/

So, our current product offering:

- FibraQ

- FibraQ PP/PE compounds

- FibraQ ABS/Hips compounds

- FibraQ 3D printing compounds

- FibraQ TPE compounds

E.E: At what stage is the market where you are currently active?

BIOFIBER: The markets readiness is a bit dependent on where the companies are located, we see that the interest is big in the Nordics and have been for the past years. But we also see growing interest all over Europe. Since most of the fairs we have exhibited at the past 2 years since we launched are in Germany, we currently have most of our customers in Sweden and Germany. But we have ongoing customer trials with brands from around 10 countries in Europe.

E.E: What can you tell us about market trends?

BIOFIBER: Well, for the past 2 years since we launched our material, we have seen a big increase in the demand for sustainable materials. On all levels, from materials for long lasting products where we have our focus to a lot of brand owners that look for sustainable packaging solutions.

Many of the large Global brands have a dedicated team that scan the globe for sustainable materials for all the company’s different needs. They will check all that is available and the potential use for the specific products or applications they offer.

We have also noticed that the search for sustainable alternatives lies not only on a sustainability mangers role, but the responsibility is shared between more people and roles. From the designers & engineers to innovation managers, business development or buyers. You can usually tell that the whole company has set a higher focus and targets on finding sustainable solutions to drive the business forward.

When starting out in 2020 we had a lot of interest from some of the large corporations that had high set goals for carbon emission reduction to 2030.

E.E: What are the most innovative products marketed?

BIOFIBER: Our core product FibraQ, since our patented technology makes it possible to offer such a wide range of compounds. Making it easy for brands that work with multiple different plastics to find a low carbon alternative to the plastics they use today.

E.E: Any big new for the start of 2023?

BIOFIBER: Well, our three main focus areas for the coming months are the scaling up of our production, the big launch in China at the China plast and new sales distribution in Europe.

We are scaling up our production to be able to deliver yearly volumes of thousands of tons this year, more news to come regarding this in a few months. This is an important milestone for the company to be able to deliver a sustainable raw material in high volumes with a consistent quality. All to have as large an impact to help reduce the global carbon emissions.

The launch in China will be done at the large China plast fair that was canceled last year but will take place this spring 17-20th of April. We will have our own stand at the fair in the Bio plastic zone, Hall 20, Booth nr: 20W71.

And concerning European distribution, more news will come later this spring…