Brinter is a trailblazing Finnish bioprinting company who provides comprehensive 3D bioprinting solutions and services for pharmaceutical, biotechnological and cosmetic industries, universities, and research facilities. Healthcare is lacking personalization of medication and care. Brinter provides the tools to serve individual needs with mass customization capabilities.

Interview with Tomi Kalpio, CEO Brinter.

Easy Engineering: What are the main areas of activity of the company?

Tomi Kalpio: 1. Pharmaceutical companies are looking at ways to develop and mass produce drugs while doing so on a personalized level – all drugs do not have the same effect on the entire population. This is where we step in.

2. Healthcare providers in especially oncology (cancer care) are doing trial and error on an individual level once optimizing drugs for individuals receiving care. We can evaluate the efficacy with bioprinted cancer models prior to actually administering any drugs.

3. The 3D bioprinting market is focused on device features and accuracy as well as pricing. We aim at providing outcomes from a healthcare perspective – patient first with mass customization.

E.E: What’s the news about new products?

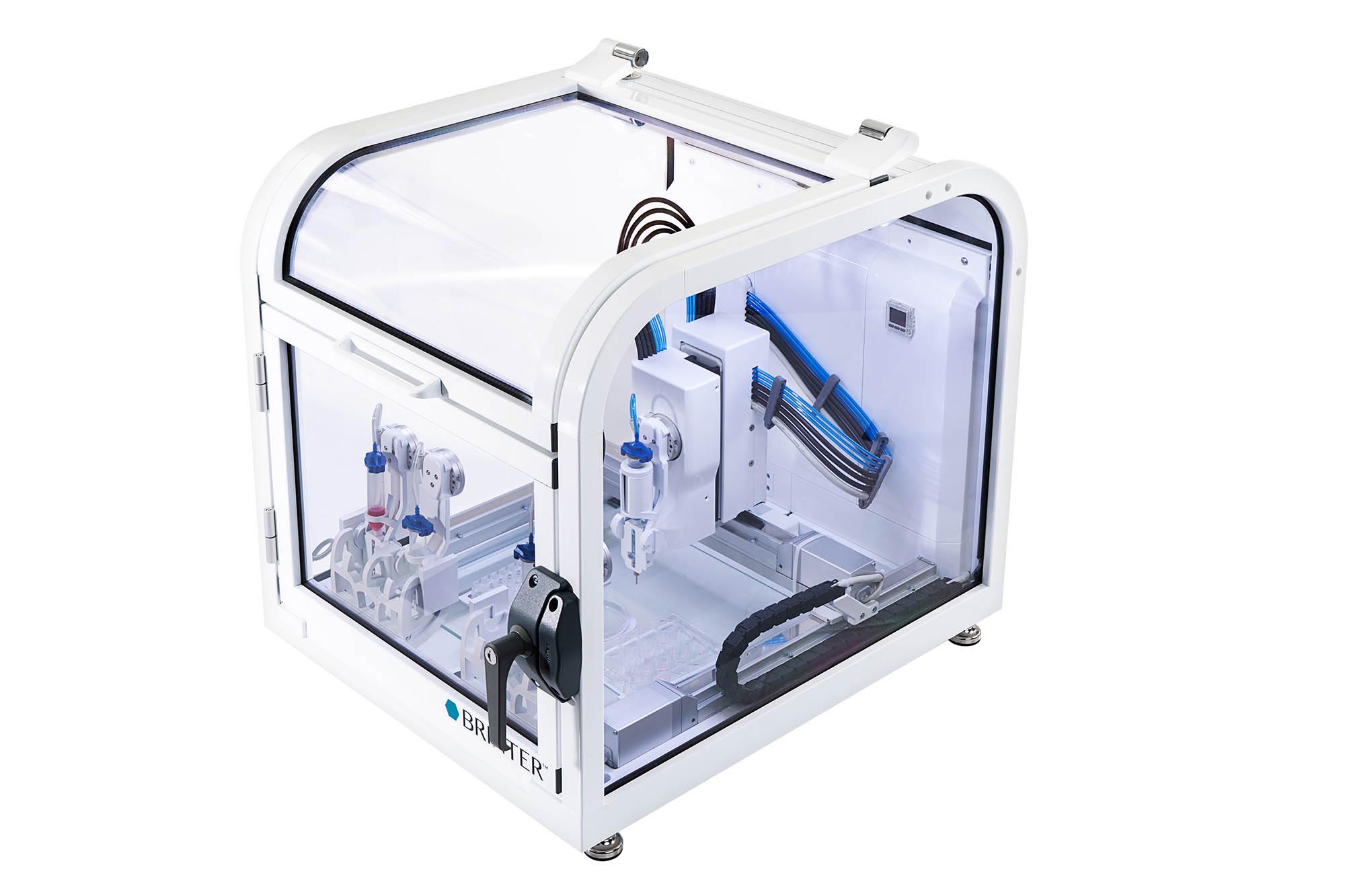

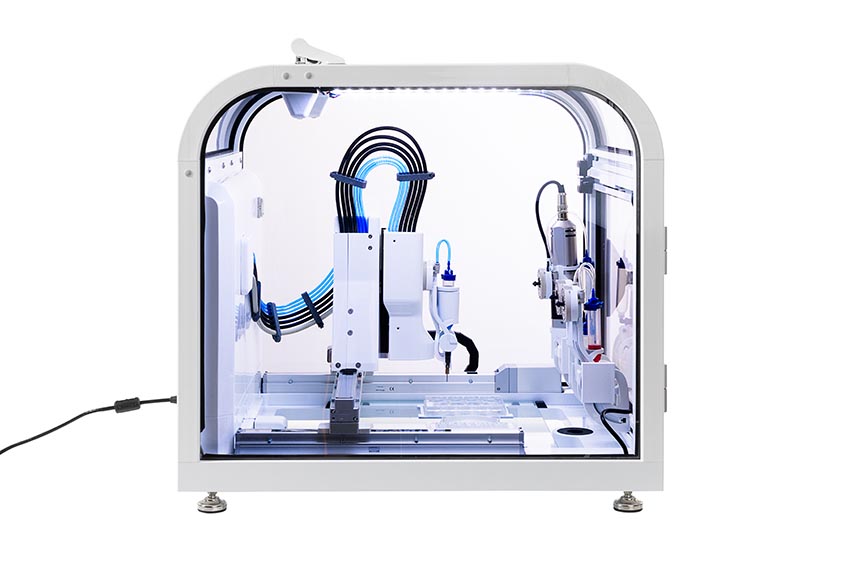

T.K: In November 2021, we launched the new entry-level 3D printer, Brinter® Core, which is 50% smaller and lower in cost, with the aim to make bioprinting more accessible to researchers and manufacturers for uses that range from personalized drugs to human spare parts. Brinter® printers are modular and that are able to print multi-material and highly complex tissue structures in 3D, providing all the features needed for bioprinting.

Also, in December 2021, we announced a partnership with LED Tailor to introduce a new disinfecting blue light module embedded in our multi-material 3D bioprinting solution Brinter®. The blue light system enables the safe production of, e.g. tissue models and drugs, and minimizes the need for separate cleanrooms, making bioprinters more portable and safe. Disinfecting blue light, while being completely safe for human beings, kills all forms of bacteria, yeast, and mold. Opposite to UV-light (100–400nm), visible blue light does not deteriorate materials or cause other hazardous effects.

E.E: What are the ranges of products?

T.K: Brinter’s product portfolio includes two multimaterial, modular 3D bioprinters, Brinter® One and Brinter® Core, and about a dozen different print heads and modules utilizing various printing technologies.

E.E: At what stage is the market where you are currently active?

T.K: The future of the 3D bioprinting market looks promising with opportunities in the pharmaceutical & biotechnology companies, research organizations and academic institutes. The market is gaining credibility through good references and use-cases that have been applied to healthcare and pharma. The global 3D bioprinting market is expected to grow with a CAGR of 26% from 2019 to 2024. The major growth drivers for this market are growing demand for organ transplantation, rise in public and private funding to support 3D bioprinting research activities, increasing use of 3D bioprinting in the drug discovery process, and growing focus of market players on 3D bioprinting.

E.E: What can you tell us about market trends?

T.K: Drug testing is one of the key market trends. 3D bioprinters are of the highest importance for drug testing and clinical trial applications expected to drastically reduce the need for animal trials (therefore not only being ethically beneficial but also being cost-effective). Traditionally, clinical trials for new drug development have involved testing on animals with artificially induced affected tissues. With the advent of 3D bioprinting, drug developers may be able to address the complications associated with human clinical trials of new drugs, by identifying them faster than ever before (since these can be tested with human-like 3D printed tissues). Thus, they are expected to reduce the losses incurred during late-stage failures. In fact, the regulatory agency of the United States Food and Drug Administration has already started to consider integrating alternatives for drug safety and efficacy assessment, providing scope for the market.

E.E: What are the most innovative products marketed?

T.K: Brinter includes fully automated print tool/print head change and automated printing while retaining full on the fly control of the printing parameters. One of the Brinter’s most innovative products is the blue-light based disinfection module. Brinter® is the world’s first bioprinter utilizing nonharmful photonic blue light disinfection to ensure the cleanliness of the Brinter® printing chamber.

E.E: What estimations do you have for 2022?

T.K: Brinter is looking at doubling its sales in 2022. US market traction and the ramp-up of our material business, as well as publishing of our new partnerships.