Brother, founded more than 100 years ago in Japan, is a company that manufactures a variety of electronic, industrial and household appliances and is one of the world’s leading manufacturers for industrial sewing machines and direct to garment printers. The company has sales and distribution branches in more than 40 countries all over the world and employs more than 40,000 people.

The headquarters for the distribution of industrial products such as sewing machines and textile printers for Europe, Africa and the Middle East is located in Germany. Including the branch office in Italy, Brother emploies over 80 people responsible for the EMEA region: warehouse and logistics experts, technicians, sales and marketing professionals, order processing specialists and staff in other fields of expertise. The Emmerich location is also the spare parts centre for the whole of Europe. More than 10,000 machine spare parts are stored there. The company delivers to customers every day. In doing so, they place unconditional value on fast delivery.

As a reliable employer, Brother also takes its social responsibility very seriously. The slogan “At your side” documents our committed, responsible and cooperative attitude in all business decisions – also with regard to the environment.

Interview with Folker Stachetzki, Head of Marketing at Brother Industrial EMEA.

Easy Engineering: What are the main areas of activity of the company?

Folker Stachetzki: Brother offer products and services with their distinctive expertise in a wide range of fields, such as the well-known printers and All-in-Ones, labeling systems and label printers, machine tools, industrial sewing machines, garment printers, coding and marking equipment, digital printing equipment, gearmotors and gears, home sewing machines, and even karaoke systems.

The Brother office in Emmerich is responsible for industrial sewing machines and direct to garment printers only, so in the following we will focus on these business areas only.

E.E: What’s the news about new products?

F.S: Of course, our in-house developers are constantly working on new models and on improving existing models. This happens in close coordination with our customers to ensure that our products fully meet the requirements of the market.

We also test new technologies and refine them until they are ready for the market.

Please accept our apology for not revealing any details about future products!

Just follow us on our social media channels, where we provide regular and timely information about innovations, new solutions and products.

E.E: What are the ranges of products?

F.S: As mentioned, we have two main categories – the Industrial Sewing Machines and the direct to garment printers.

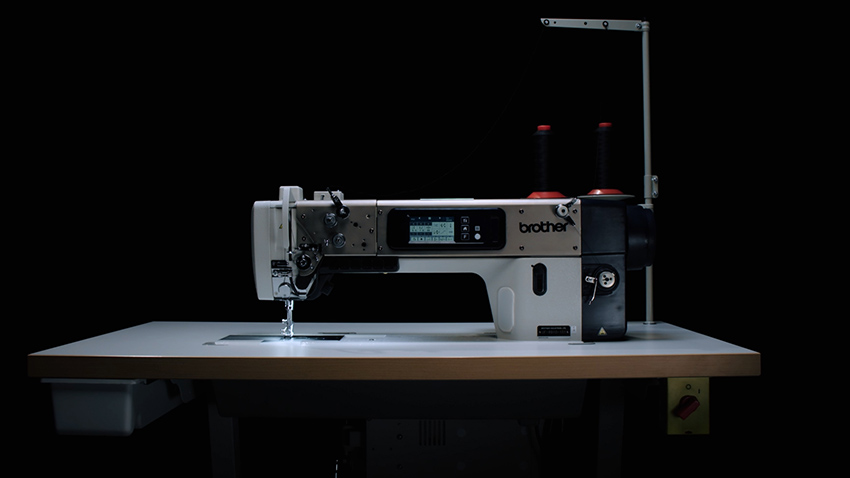

We distinguish between 12 categories of industrial sewing machines. From single needle machines to programmable electronic pattern sewing machines and bonding machines, we cover a wide range of production solutions.

In the direct to garment printer sector, we currently have three models in the GTX series: The GTXpro, this one is perfect for unique, individual and personalized prints where creativity knows no boundaries.

Based on this we offer the GTXproBulk, which is perfect if you want to do higher volume output.

Our GTXproBulk comes with high-capacity ink tanks and sub ink tanks and our latest model. The GTX600 was especially developed for mass production and was only launched a few months ago. Nevertheless, this mass production machine can already be found in many large production facilities.

Our entire product range can be found on our websites.

E.E: At what stage is the market where you are currently active?

F.S: Due to the two different industrial product groups that we distribute, their markets are also significantly different.

The market for industrial sewing machines exists already since many years and is very well saturated. The end customers have mostly been active in this segment for a long time and usually have highly specialised production factories.

The technology has also been established for a long time and only a few, mostly the market leaders, manage to establish innovations.

The market for direct to garment printers, however, is still quite young and dynamic, with about 20 years existing.

The target group is also much more diverse in their production range. Our customers can be found in all segments, from the production of very small series or individual, personalised single prints to mass production.

Of course, both markets have suffered from Corona and are currently suffering from the energy and economic crisis. Fortunately, both markets are in a relatively good position and have been able to recover a significant part of their losses.

E.E: What can you tell us about market trends?

F.S: Two trends that both markets have in common are digitalisation and sustainability.

In both areas, it is becoming increasingly important that productions and thus the machines used become internet-capable and “smart”. Many large manufacturers have developed solutions in this regard in recent years and this development is continuing and even accelerating.

Sustainability in both areas refers to the production chain of the machines as well as durability.

Here, too, the market leaders are striving to optimise the machines, use more sustainable materials and thus reduce the impact on the environment.

A big trend that we have been seeing in the last years now is that productions are increasingly being built locally again.

Even large companies are moving their production back to Europe.

E.E: What are the most innovative products marketed?

F.S: This is a difficult question to answer, as we are naturally biased and the term innovative can mean something different to many – depending on what they produce or where their core competencies are.

From our side, these are of course our new machines such as the BM-2000 bonding machine in the sewing segment, which glues and does not sew, and the digital solution “Myze” in the textile printing segment, which digitally supports all aspects of production.

In general, however, it can be said that products that serve the above-mentioned trends of “digitalisation” and “sustainability” and generate real added value all deserve to be called innovative products.

E.E: What estimations do you have for the rest of 2022?

F.S: Despite the possible threat of crises, we are feeling reasonably positive about the near future.

We and our core markets are well positioned and the last few years have shown that it is worth it to manufacture high-quality products and for customers to implement them. Also, because of our expertise and the fact that all our products are developed in-house, we can react very quickly to changing circumstances. This benefits us and most especially our customers.