Calibre Control International was founded in 1988 with a focus on providing the food and beverage industry with a wide range of state-of-the-art testing technologies to ensure quality and safety. Today’s consumers demand the highest standard in food safety and food quality. Calibre’s mission is to ensure customers have access to the best quality testing equipment and are supported in their mission to supply nutritious produce to the global food industry. Using modern screening processes, they’ve brought together a comprehensive range of testing equipment that meet food safety and quality testing requirements. Along with their highly knowledgeable staff base, Calibre is always on hand to assist and point customers in the right direction.

Key to their success is meeting the needs of customers and adapting to the ever-changing world of food safety and quality. The company takes great care in only promoting testing solutions that have an established record in accuracy, speed, ease of use, cost effectiveness and regulatory approval.

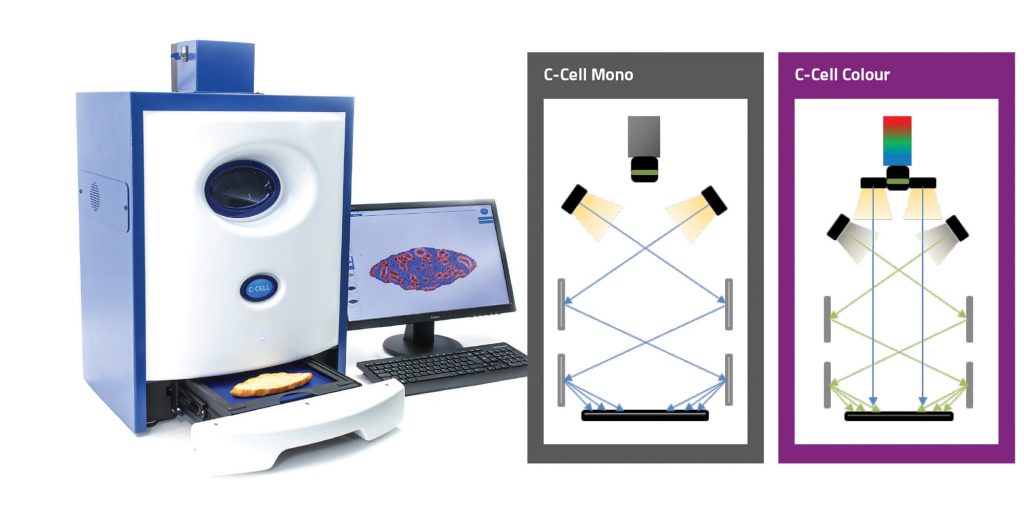

The C-Cell analyser is a unique imaging system that enables detailed characterization of the internal and external structure of aerated objects, both food and non-food, which is used widely in over 30 countries.

Interview with Madian Abu-Hardan, Global Product Manager at Calibre Control.

Easy Engineering: What are the main areas of activity of the company?

Madian Abu-Hardan: The C-Cell analyser is used by a broad range of customers from various industries, some of which are: Bakery equipment manufacturers, Improver, ingredient and yeast manufacturers, Flour millers, Cereals and food research organizations, Wheat breeders, Plastic foam manufacturers, Pet food manufacturers, High volume bakeries and many more.

E.E: What’s the news about new products?

M.A.H: The C-Cell analyser’s latest software will enable the connection of multiple instruments in various customer site locations to establish central data collection and analysis, and to facilitate decision making.

E.E: What are the ranges of products?

M.A.H: C-Cell is available in a number of configurations/software versions & data outputs:

- Monochrome standard (Standard 48 parameters)

- Monochrome advanced (Standard 48 parameters with cell data on 5 parameters).

- Monochrome High Resolution (HR) Standard (Standard 48 parameters)

- Monochrome High Resolution advanced (Standard 48 parameters with cell data on 5 parameters)

- Colour Standard (with Bread Score module)

- Standard 48 parameters

- Crust analysis

- Crust thickness and colour

- Crumb colour

- Bread Scoring module

- Colour Advanced (with Bread Score and inclusion analysis)

- Standard 48 parameters

- Crust analysis

- Crust thickness and colour

- Crumb colour

- Bread Scoring module

- Inclusion module

- Colour High Resolution

- Standard 48 parameters

E.E: At what stage is the market where you are currently active?

M.A.H: Historically, and for example in the food industry in general, quality assessment of aerated products was done in the traditional, subjective way, which led to inconsistent and less accurate corrective actions. This was also driven by the lack of a proper technique that was suitable for analysing aerated structures. The C-Cell provides objective and independent measurements with high accuracy; allowing the removal of subjectivity and a focus on higher level detailed analysis, that promotes and encourages more targeted and accurate resolutions to key quality problems. With little to almost no competition with the C-Cell, demand has soared and due to the unique software, the scope of applications beyond aerated foods is continually being expanded and gaining interest.

E.E: What can you tell us about market trends?

M.A.H: Quality control and quality improvement has been ever a hot topic and being able to accurately analyse open structures has always been a main focus for example, in the food industry. Accuracy, speed, ease of use, reducing waste, and value for money are qualities that sit at the top of the list of any manufacturer. The C-Cell imaging system provides answers to all these needs; hence we expect the demand for our system to grow even more and to cover more applications beyond food.

E.E: What are the most innovative products marketed?

M.A.H: Some of the innovative solutions offered in the market are flatbed scanners and off-the-shelf imaging software to develop bespoke in-house systems. However, these are very much one-off, and results cannot be duplicated in another system. Other imaging systems can only measure external characteristics of a product or object and not the internal structure. The C-Cell is a robust, easy to use technique that can be operated in various environments such as production facilities, R&D centres, labs, mills, bakeries…etc., and is the only system that can produce detailed results about the internal and external structure of an aerated or open structure object.

Our strategy at Calibre Control is to continue promoting our solution via website articles, exhibitions & conferences to food and non-food industries, and engage with companies to ensure the best use of the technology.

E.E: What estimations do you have for the rest of 2022?

M.A.H: 2022 has been a great year for us and we expect to install more units in the coming couple of months towards the year end. Our technology is sold across the globe and used by various sectors, helping our clients to better control and improve quality, saving them time, reducing waste, reducing customer complaints and making them money.