Easy Engineering: How was this year in terms of turnover?

CEFEG: In 2020 we made a turnover of about 10.45 million €. Hence, we can slightly increase our turnover compared to 2019. Compared to our business plan we reached about 87 % against optimum scenario. Looking back, we weathered the Corona crisis comparatively well.

E.E: What new products / services have been launched this year?

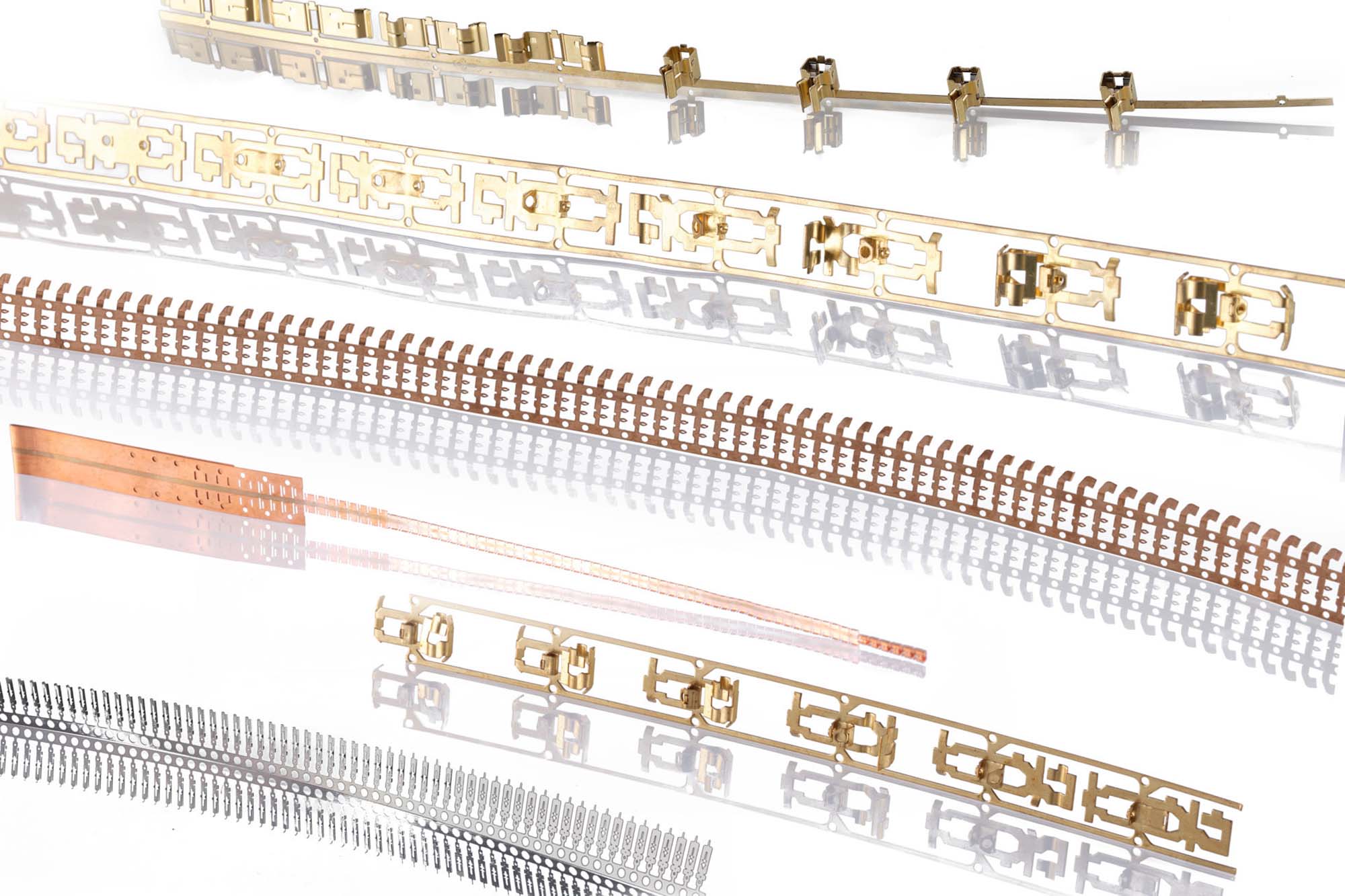

CEFEG: CEFEG GmbH is a SME company, which produces stamping and bending parts with complex forming degrees, technical springs as well as assemblies on request of our customers. We design and create efficient manufacturing tools for this application. Hence, we did not introduce new products or services to the market in 2020, but we broadened our technology portfolio by buying a new Bruderer punching press (BSTA-410), installed laser welding on this press and optical measurement system for process control to be able to produce contacts for electronics industry. Furthermore, our portfolio is supplemented by multiple take-up reels for spooling punching strips on reels for further processing.

We have recorded a training video for a tool set-up and tool conversion on a modern automatic punching and bending machine from Otto Bihler Maschinenfabrik. This was a request of our customer due to Corona reasons and we offered it as an additional and paid service. We are now familiar with this and we can imagine offering such services in the future as well.

We put much effort in making our processes much more efficient and pushed digitalization within administration and production forward.

E.E: What feedback did these product / service launches have?

CEFEG: This is hard to evaluate, because everything we produce is based on requests from customers. We note that our customers were really satisfied about our flexibility, delivery performance and active communication during pandemic.

E.E: What products / solutions have customers been looking for this year?

CEFEG: We see an increased demand for complex components with a high level of vertical range of manufacture. That’s why we did our latest investment in technologies.

Besides this there was no significant change in the needs of our customers in 2020. We have a wide range of branches we serve. Market fluctuations were offset by growing demand from other markets. Additionally, 2020 has shown us the importance of diversity, adaptability, flexibility and service.

E.E: How has the customer profile changed lately?

CEFEG: It seems that big companies start to reduce the number of suppliers. This is somehow unexpected because up to now diversity in the supply chain was one key element. Companies becoming more cautious for example with forecasts or stock build up. The need for communication becomes greater whereby our customers appreciate our active and regular feedback. We have especially noticed that the sense for supplier´s consistency is growing the more.

E.E: Given the current context, was there a need to diversify the portfolio of services/products?

CEFEG: We note a trend that customers are looking for absolutely reliable and flexible suppliers. Especially in automotive industry, requirements from customers become much more complex. Therefore, research and administration issues increase and need to be handled. Issues regarding security of information rises and standards are transferred to the companies within the supply chain. Customers would like to have the „all-inclusive package” with high customer care, a high service level and active communication.

E.E: What was the most important project this year?

CEFEG: There was not this one important project, there were several. From the technical point of view, we started production with a new and really demanding customer, which means to put new technologies in operation and establish new processes in the company. Besides this, creating and establishing hygiene concept and occupational safety standards due to pandemic situation, maintain active communication with employees and production processes was a key issue.

Another challenging project rises with designing and structuring the process of handing over the company from father to daughter, where different generations and thus also different management styles met. From this a project regarding creation and establishing a new leadership culture in the company arises, where executives as well as employees had the chance to contribute. This is still an ongoing process in 2021.

E.E: A short year-end message for collaborators.

CEFEG: Stay curious, look forward and stick together. Take new challenges as a chance to find new and better solutions together.