Cerealto Siro, a multinational company in the food sector and a client of Radar Process, has production plants in Spain, the UK, Italy, Portugal and Mexico, and its core business lies in the production of Cookies, Breakfast Cereals, Snacks and Pasta for large brands or distribution brands.

Mr. Sergio Barreto, the Engineering Manager at the Cerealto Siro plant in Tepeji, Mexico, has led the project for the automation of the ingredients in its 4 biscuit production lines, which began in 2019.

The aim of the project was to guarantee the accurate weighing of the majority ingredients (flour and sugar), reduce the number of safety risks such among its workers, especially lower back pain increasing client confidence by the reduction of foreign matter contamination as well.

How were operations carried out in the factory before the project was introduced?

Cerealto Siro: Flour and sugar was added manually. Up to 220 kg of flour and sugar, in 40 kg bags or sacks, were poured in each of the four kneaders at a rate of 2 batches per hour for each kneader. This process led to a large amount of physical work, injuries, significant quantity errors, safety risks from foreign matter entering the dough, and a significant need for low-skilled labor involved in the process.

What general benefits have come from the project?

Cerealto Siro: Thanks to the implementation of the automated handling of ingredients, we can guarantee greater operator safety, as well as an improvement in the workforce’s general well-being, by reducing arduous or uncomfortable work. It also allows us to have an accurate inventory control, reliable weighing, and dosing with a margin of error of less than 1%. Thanks to the careful monitoring of the process, we have eliminated the risks of foreign matter appearing in the dough.

Why is an automated ingredient handling facility good for food safety?

Cerealto Siro: The main ingredients are dispensed from closed systems, in the form of 75-tonne silos, which are automatically fed from tanker trucks. These ingredients are not exposed to the environment or any type of handling at any time, and go through different processes including sieving, filtering and the retention of ferrous elements using magnetic detectors. Spills are largely avoided, as the ingredients are handled in closed pipes via as part of a pneumatic conveying process.

What can good traceability software do for food safety when it comes to ingredient handling?

Cerealto Siro: In the event of a food safety scare caused by a defect in an ingredient, the software identifies the issue in a timely and precise manner. In the event of a contingency, it identifies the batches to be retained with just one click on the traceability system. This makes for a safe finished product and improves guarantees from the commercial area to the customers.

Flexibility: Surely a manual plant offers greater flexibility?

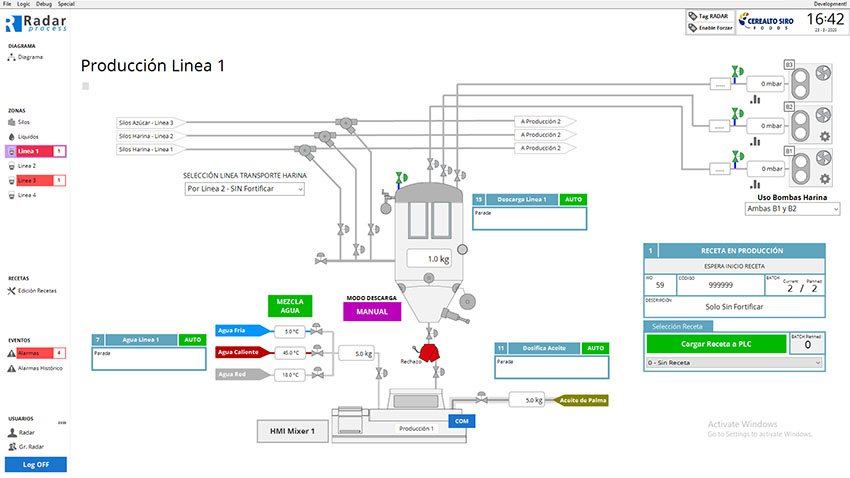

Cerealto Siro: In principle, yes. However, all products in our operation require flour and sugar, with this automated system all modifications to recipes from one batch to the next are carried out automatically based on predefined recipes that the operator can change with a single click.

How can a Radar Process system, and the information it provides, help out?

Cerealto Siro: The automatic dosing system offers significant benefits when it comes to inventory control. It is very quick and easy to obtain consumption data and view it either altogether, by recipe, by customer, by ingredient, or via any other method of analysis that you wish to carry out. The silos containing the main raw materials rest on load cells that provide us with the stock in each one at all times.

How was the experience of implementing the project?

Cerealto Siro: It was a challenge, it involves a significant change to the layout, and continuing with production during the transitional phase was not easy. Modifying the feeding of the mixers while continuing to knead as part of production was not an easy task, and the process had to be organized very well.

The project stakeholders were fully involved in the implementation of the new system, which facilitated decision-making and the correct implementation of the project.

Technical support from Radar was always available from receipt of equipment to start-up.

Challenges:

Despite offering improvement, the operational change for employees and involvement of maintenance staff was a significant challenge. Fear of a new system made adaptation difficult.

It was important to be very rigorous in the final phases of the project, in order to obtain the benefits that the system can offer in terms of speed, precision, etc. It was very important to not delay this period in any way.

The combination of a new system and the operators limited experience and training led to repeated damage to key parts within a short space of time. It was very important to have spare parts for the initial phases. Any problems that occurred at the beginning of the operation had a negative impact at the beginning of the return on investment period.

It must be said that, following on from this initial period, the system has proven to be very robust, and can be trusted.

We wanted a reliable, sustainable system that would fulfil our initial objectives, and that has been achieved.