Cestriom has been founded in the beginning of 2017 by Marek Rohner. The founder has professionally worked for many years in the field of industrial demagnetization prior to foundation of Cestriom. Since 2017 until mid 2022, the company has sold nearly 100 demagnetizing machines to many different industries and countries. Many of them are working in 3 shifts in automated production environments.

Interview with Marek Rohner, Founder of Cestriom GmbH.

Easy Engineering: What are the main areas of activity of the company?

Marek Rohner: The focus of the company is to develop and to sell state of the art demagnetizing machines and to provide demagnetization services.

E.E: What’s the news about new products?

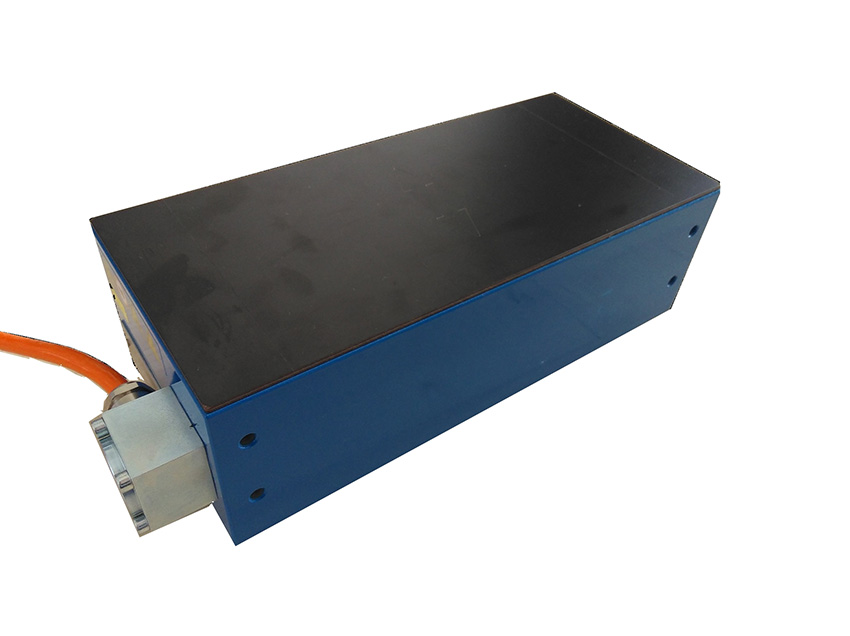

M.R: The most recent product development we made is to enhance our range of industrial demagnetizers to larger sizes and higher power levels. Now we can deliver power modules LM90, LM120 and LM150 which can power large coils with high field strength. We continuously expand and improve our product portfolio, to be able to meet customers’ requests in a best possible way.

E.E: What are the ranges of products?

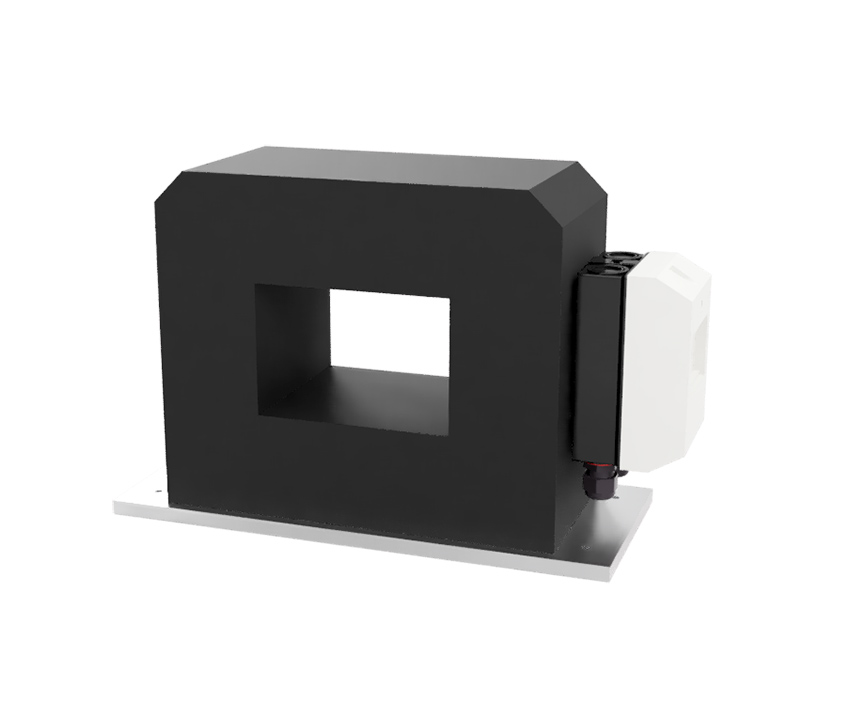

M.R: Our main product is the industrial demagnetizer range. These demagnetizers consist of a power module and a coil. We deliver these machines in many different sizes. Usually, they are configured as impulse demagnetizers.

The second most important product is the mobile demagnetizer range MGFE. This demagnetizer works with magnetic field cables and is used mostly for the demagnetization of larger single parts or whole machines.

To complete our program, we also provide standard tunnel coils, yokes or plate demagnetizers and also magnetic field measuring instruments. Some of these products are reselled from other OEM’s.

As services we provide demagnetizing services at clients’ site, inhouse demagnetizing at Cestriom location. We also have a rental demagnetizer program that we are continuously expanding.

E.E: At what stage is the market where you are currently active?

M.R: Demagnetization is not a new topic in general. However, we are observing growing interest in demagnetization in industry due to many reasons. Some of the most important are listed here below:

- Industry is increasingly using magnetic lifting, handling and clamping systems

- High performance steel tends to have higher magnetizability due to higher hardness and therefore higher coercive field strength

- Testing systems and sensors based on eddy current and magnetostriction principle are increasingly used in industry

- High cleanliness of steel parts needs often demagnetizing parts prior to parts cleaning processes

There are clients who already have quite a deep knowledge about demagnetization. But according to our experience most of our new clients have no or very little knowledge about residual magnetism and demagnetization. These buyers need guidance to invest in the right demagnetizing equipment. Demagnetization is a topic that needs explanation.

E.E: What can you tell us about market trends?

M.R: From a technological standpoint there is a trend towards impulse demagnetizers. Such systems provide much higher performance than conventional pass-through demagnetizing coils or common plate demagnetizers. Other important advantages of impulse demagnetizers are the increased operator safety and the usually smaller footprint in the factory. Demagnetization is just triggered by placing the parts in the coil and by pushing a button on the power module – or in the case of automation by sending the appropriate signal.

E.E: What are the most innovative products marketed?

M.R: Our mobile demagnetizing system MGFE has unique selling points in terms of performance vs weight/size. The whole equipment including mobile power module, magnetic field cables and adapters can easily be transported by a normal car. The MGFE demagnetizing system can also be adopted/enhanced to perform optimally in specific applications. Example: We developed for a large automotive supplier a handy tool surface demagnetization coil that is used in combination with magnetic field cables to demagnetize stamping tools.

E.E: What estimations do you have for 2022?

M.R: The perturbations in the world due to Covid19, delivery chain disruptions and the actual Ukraine war have also an influence on our sector. Our clients were reserved with orders in the first two quarters and are now catching up on orders. A lot of our customers are special machine builders which are having delays due to the delivery chain disruptions. That also means the duration for projects became much longer than normal. Despite all we have quite a good order situation right now.

Phone: +49(0)7223 915 2017