Chromatic 3D Materials is a 3D-printing technology company founded on a novel type of additive manufacturing that uses chemical reactions. Chromatic’s RX-AM™ platform encompasses materials, software, and hardware.

Interview with Dr. Cora Leibig, Founder and CEO of Chromatic 3D Materials.

Easy Engineering: What are the main areas of activity of the company?

Cora Leibig: Chromatic develops printable polyurethane materials for industrial applications. The RX-AM™ platform is suitable for 3D-printing finished seals, gaskets, and bladders, as well as intermediate components that require further milling or lathing, such as billets. Chromatic can print commercial volumes, and we also sell compatible printers and software so that customers can employ Chromatic’s additive manufacturing capabilities onsite.

E.E: What’s the news about new products?

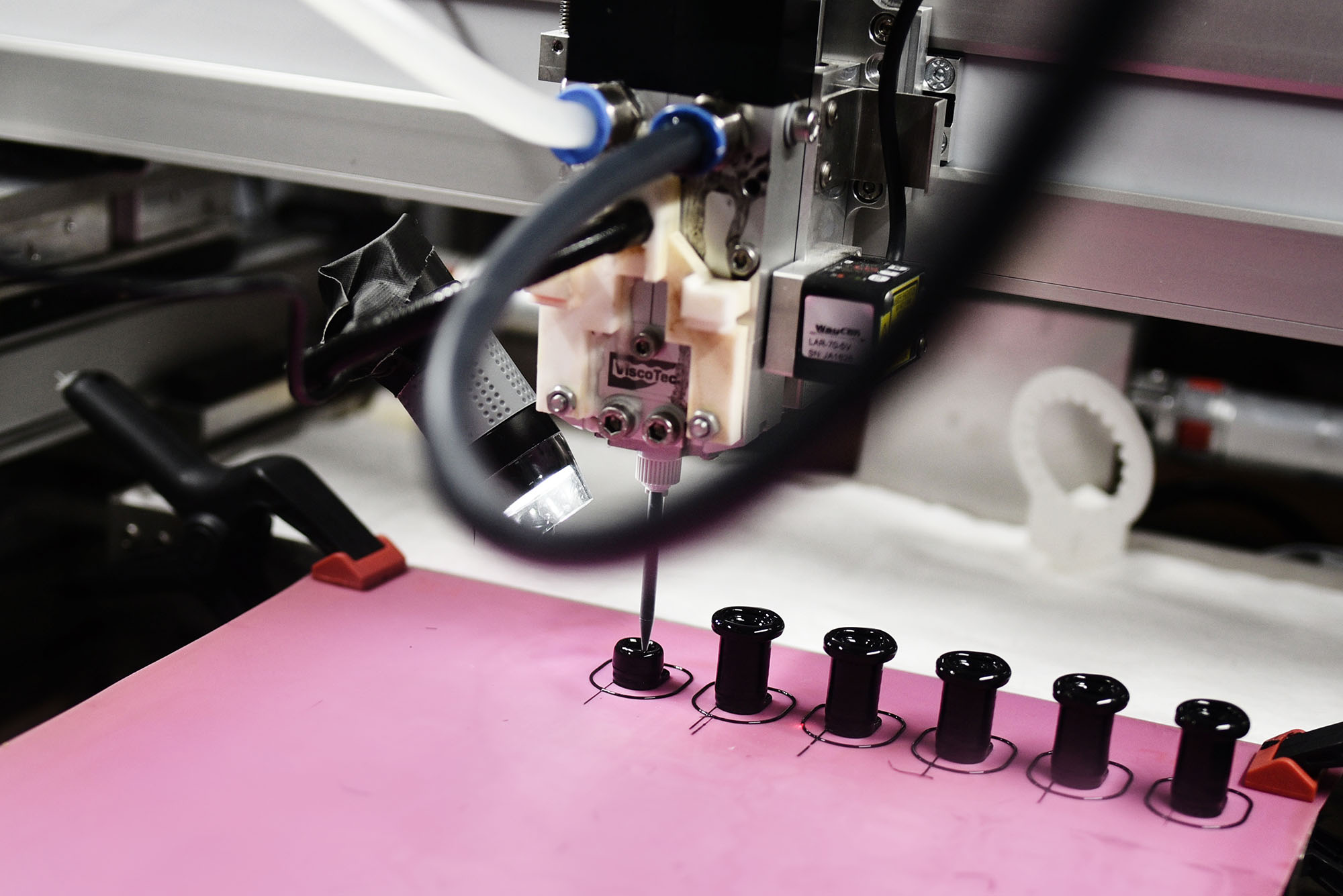

C.L: ChromaScan is a proprietary additive manufacturing software for 3D-printing resin onto non-planar surfaces, whether the substrate is metal, plastic or even a textile. The result is industrial-strength adhesion between the printed material and the substrate, without additional assembly steps.

Smooth-Mode is another new technology that enables 3D-printing commercial volumes of durable rubber parts with ultra-smooth surfaces — with no post processing or surface finishing required.

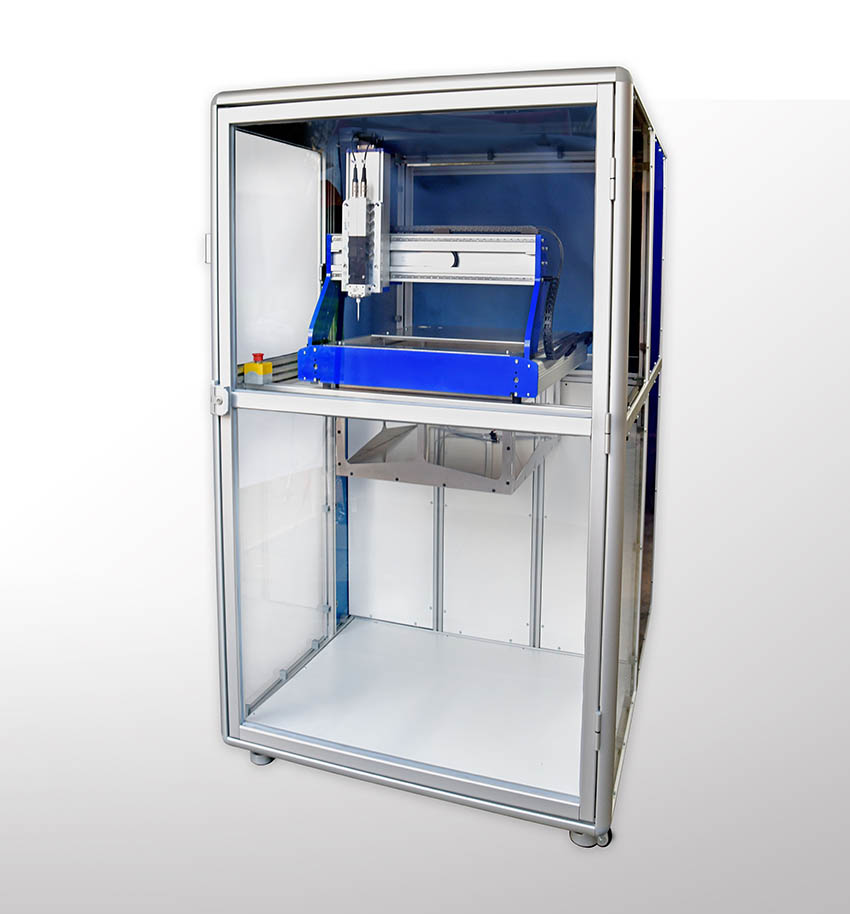

Lastly, Chromatic recently launched RX-Flow™, a line of 3D printers for reactive extrusion additive manufacturing with thermoset polyurethanes. Designed for development work and low-volume industrial production, RX-Flow™ printers are a low-cost option for manufacturers interested in testing and implementing industrial 3D printing with more durable, flexible materials than are available with FDM, SLA, and other 3D printing technologies.

E.E: What are the ranges of products?

C.L: Chromatic’s printable polyurethanes range from Shore A hardness 50 to 90. We also develop custom grades with varying colors, hardnesses and special properties (e.g. antibacterial, static discharge, biocides, etcetera).

E.E: At what stage is the market where you are currently active?

C.L: Use of 3D printing in industrial markets is very early. Most of the usage has been focused on tooling fixtures for mechanical equipment, but for actual finished parts going into manufacturing, this is emerging technology.

E.E: What can you tell us about market trends?

C.L: 3D printing is growing 20% year over year, and much of that growth is happening in the industrial market. So, in the industrial market, it’s growing even faster than 20%. Overall, prototyping as well as tools and fixtures are driving a lot of the 20% growth, but the growth within manufactured goods is accelerating rapidly.

E.E: What are the most innovative products marketed?

C.L: Chromatic’s ChromaScan printing software enables manufacturers to print resin directly onto non-planar substrates — something that’s challenging for other 3D-printing technologies. For example, we used ChromaScan to print durable rubber track pads directly onto aluminium plates for a tractor.

ChromaScan opens up a world of design possibilities, as well as more streamlined, cost effective and sustainable manufacturing. The print application is precise, with higher pass rates and better print quality, and it can reduce or even eliminate post processing and assembly processes (like adhesives and stitching). Benefits include faster and more efficient production, fewer labor and materials costs as well as a reduced environmental footprint with less material waste.

Smooth-Mode printing is a breakthrough for applications that must seal perfectly against air or water. Whereas other 3D-printed components have layer lines or roughness, parts printed with Smooth-Mode do not require any post processing to achieve an ultra-smooth finish. In addition to superior aesthetics, Smooth-Mode offers excellent dimensional accuracy. (For example, products can be printed with precise uniform thickness at submillimeter scale.) Thus, the new technology is suitable for manufacturing rubber bladders and other elastomeric products that expand and contract.

E.E: What estimations do you have for the rest of 2022?

C.L: Chromatic is building out its RX-Flow™ printer offering so that we can show the market the types of standard shapes that we can print very readily, such as bellows, grommets, and other elastomeric parts.