Color Service was founded in 1987 and it’s the world leader in the development and production of Automatic Dosing Systems. With a start in the Textile field and thanks to over 30 years of experience and know-how, Color Service has introduced in 2009 the first Full Automatic Dosing System for Rubber and Tire Industry, solving many of the problems present in the manual weighing of any powder product.

With more than 2500 systems installed worldwide, the company has consolidated its position satisfying customer’s need to automate the raw material dosing in several countries: in America, Europe, Africa and Asia.

Their Systems guarantee High Dosing Accuracy through several devices, Batch Traceability to monitor all the processes, Environment Respect reducing the pollution, the energy and the air consumption and Modularity of individual stations.

Easy Engineering: What are the main areas of activity of the company?

COLOR SERVICE: Color Service is currently involved in Technical Rubber, Tire, Plastic, Textiles and Cosmetic Industries.

E.E: What’s the news for 2021 about new products?

COLOR SERVICE: This year Color Service will work on a new plant concept, a new paradigm based on the 4.0 revolution and the IoT looking forward to satisfying the market needs in terms of high productivity, 0 risk, sustainability, and high flexibility in the logistic of the process. Thanks to the technological transfer and vision provided by our expert partners, combined with the huge know-how of our engineers, our R&D team will have the pleasure to present its own innovation in the Tire Industry Manufacturing Process. The concept of development is based on the introduction of the Automatic Bag Delivery to customer’s mixer providing a complete line, from the creation of the bag to its delivery to the mixer and the Variable Bag Size which allows the automatic adjust of multiple bag size with recipe volume.

E.E: What are the ranges of products?

COLOR SERVICE: Our products and services include the study, development, manufacturing and turnkey delivery of Automatic Dosing Systems for Small Chemicals Weighing of powder and liquid products.

The Dosing System can be flanked by an Automatic Storage System which automates the collection of the boxes containing the powders according to the recipe.

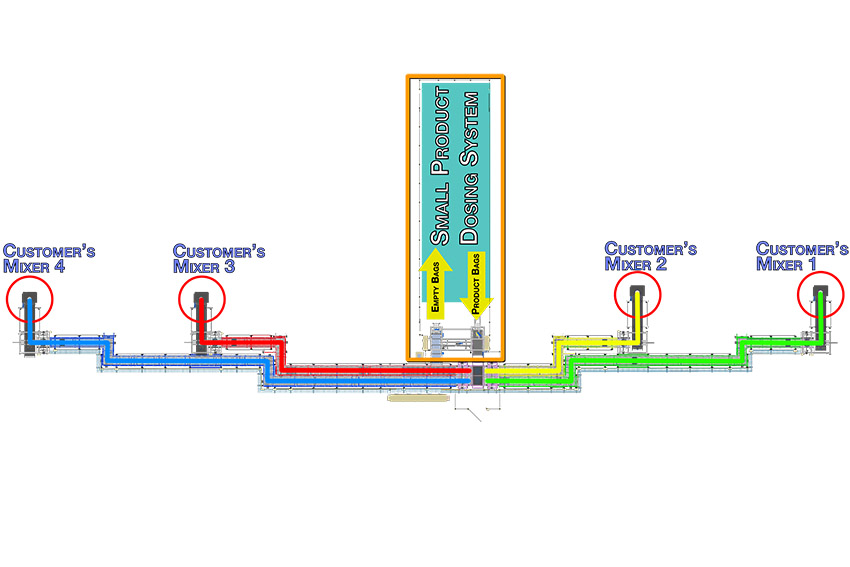

At the end we provide an Automatic Delivery System to transport through roller conveyor the dosed bags directly to customer’s mixer.

In addition, we provide a 24/7 assistance service that guarantees the customer the continuous support of specialized technicians available remotely or on site in case of any problem, as well as providing preventive maintenance visits to the system, to keep it always in good condition and monitored.

E.E: At what stage is the market where you are currently active?

COLOR SERVICE: Thanks to the technology innovation applied to the manufacturing activities, the sensitivity towards automation and the respect for the environment are constantly growing. We have entered these sectors by bringing important innovations allowing a consistent production, very precise recipe avoiding human error and absolute control of the dust emitted during the product’s dosing and weighing phase, suitable to meet the current regulations in terms of environmental safety.

E.E: What can you tell us about market trends?

COLOR SERVICE: The increasingly current trend is the introduction of automatisms and robots in the manufacturing industry with the 4.0 Industry.

Color Service systems are designed and customized according to customer’s needs, guaranteeing an increase in productivity and production quality and a substantial improvement in the working conditions of employees as well as significant energy saving.

E.E: What are the most innovative products marketed?

COLOR SERVICE: The most innovative and successful product is the dosing device for the tire manufacturing. This revolutionary device guarantees 2 bags (small chemical recipe) per minute, high productivity, autocleaning and it’s very fast and accurate, ideal for high consumption products. Furthermore, it’s completely closed and aspirated guaranteeing 0 emissions in the environment and protecting the operator from inhalation of possible harmful dust during the dosing, vital from the environmental and safety points of view. While talking about logistic and IoT at first, we also want to say that we have a new front of research that will provide a new version of the dosing system. This will allow higher rates of production and more flexibility to help producers low down set-up and internal cost for different raw materials.

E.E: What estimations do you have for 2021?

COLOR SERVICE: The main objective is to introduce our technological innovation to new customers, in order to allow them take advantage of all the benefits that our systems can offer and improve the production reality.

Our target is exploring the Plastic Industry that it’s a very ample sector but at the same time very stimulating and we plan to spread our technology and offer innovative and high quality machinery.