Combicore GmbH was founded in 2016, develops and manufactures patented Combicore casting cores for modern cast parts near Kaiserslautern in southwest Germany. Years before, these innovative cores were successfully introduced together with partners and marketed worldwide.

With the multiple award-winning and patented Combicore technology, cores are also used reliably in die casting for the first time. This creates very light components with an efficient channel structure and cavities, which are required, for example, to cool components.

Combicore has already successfully established itself as a brand in the automotive and foundry industries.

As a metal processor, the company is active in metal forming. This includes bending pipes and wires as well as processing sheet metal. Suitable joining techniques, such as welding or soldering, create complex assemblies for the B2B and B2C markets.

Customers appreciate the high quality standards of the products, the comprehensive advice and the advanced techniques of the research and development department.

Easy Engineering: What’s the news about new products?

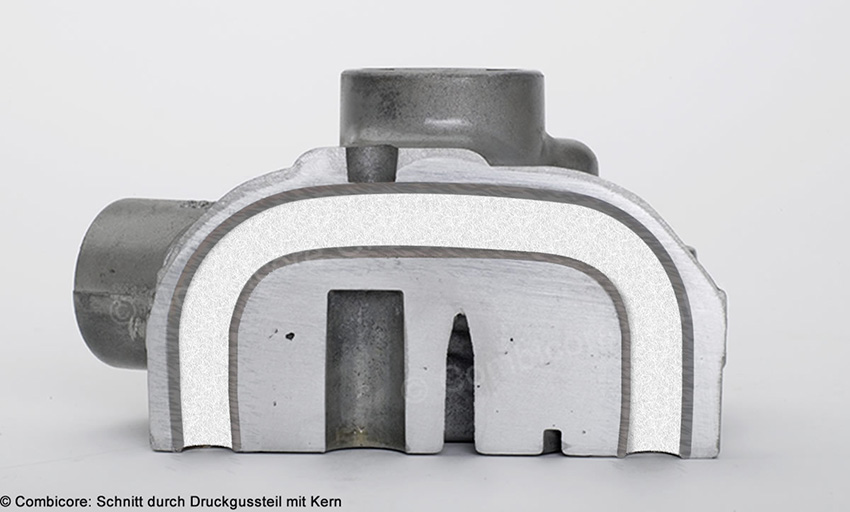

COMBICORE: With the Combicore technology, casting cores can for the first time also be used in die casting with casting pressures well over 1200 bar. Combicore GmbH is the leading manufacturer of these patented cores and has continuously developed and optimized them over the past decades. The Combicore core consists of a shaped metal casing, often made of very thin aluminum, which is filled with a special material. The cavity that will later be required in the cast part is mapped with the core. Combicore cores can be used in all casting processes.

Customers appreciate the numerous advantages of Combicore technology, with which extremely light cast parts with efficient performance can be realized. Thanks to an optimized design, the cast part can follow the integrated channel wall and be cast near net shape. The material required is reduced and saved. In addition, lightweight components also consume less energy in later operation. Due to the great freedom of design, the flow resistance of the coolant can be optimized at the same time. If necessary, the company also supports its customers with the later core removal.

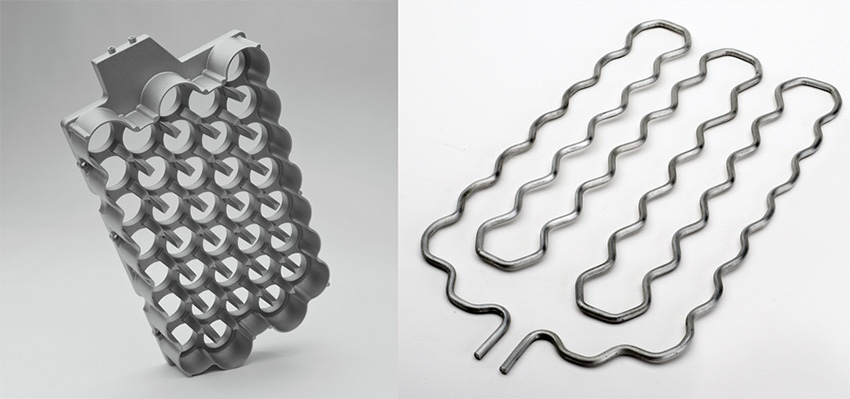

The casting core production is supplemented and expanded by the forming technology. For example, bent wires and other shaped parts create complex core packages. Metal items are also manufactured for other markets and customers, such as heat exchangers or consumer items for end customers. We process aluminum, steel, stainless steel, copper and other alloys.

Comprehensive advice, technical support in construction and design as well as the development of innovative components round off the Combicore GmbH portfolio.

E.E: What are the ranges of products?

COMBICORE: The know-how of the employees covers a wide range of industries, with Combicore GmbH having three main production areas:

In terms of core technology, we produce Combicore casting cores for the world market and work closely with well-known OEMs and foundries.

Metal articles for dealers and private end customers are produced in metal forming technology. In order to obtain suitable metal structures for further processing, we also carry out heat treatments.

The joining technology ensures firm connections of core packages or metal assemblies and thus also connects the two aforementioned production focuses of our company.

All three production areas are supplemented and supported by our development and design department. We work closely with customers and develop individual solutions and innovative applications together. With our comprehensive technical advice, cost-effective solutions are implemented.

Combicore casting cores are used in numerous applications. With their great freedom of design, they offer numerous advantages in the automotive sector, where lightweight construction and material efficiency are key criteria for success.

E.E: At what stage is the market where you are currently active?

COMBICORE: Everyone knows today’s challenges in the automotive industry, in which we are primarily active. Electromobility, fuel cells, but also the solar industry – Combicore technology makes sense in a variety of areas.

Climate protection is also particularly important to us and we try to produce largely CO2-neutral. In our opinion, the environmental goals can only be achieved through innovative manufacturing processes and products. Resources are finite and must be used sensibly and profitably for everyone. Combicore products make an important contribution here and offer real added value.

E.E: What can you tell us about market trends?

COMBICORE: The sensible consumption of energy and the effective use of resources will continue to play a central economic role. However, we see the risk that users cannot or will not initially be able to afford new technologies because of the high prices.

We rely on high-quality technical solutions that can be manufactured at low cost and in very large quantities. This enables rapid market penetration so that all sections of the population can participate in technological progress relatively quickly. We support central technical challenges in the automotive industry, such as lightweight construction and thermal management.

E.E: What are the most innovative products marketed?

COMBICORE: Combicore manufactures innovative casting cores for all casting processes. For the first time worldwide, stable cores can also be used in die casting with casting pressures of well over 1200 bar. With this core technology, numerous innovative and future-oriented products with new geometries are marketed. For example, the Combicore technology can be used to produce lightweight cast parts that also require less energy during operation later on and are resource-efficient. Our customers implement innovative applications with Combicore cores. Many are new to the market.

E.E: What estimations do you have for 2022?

COMBICORE: We hope that we all stay healthy, that Corona will affect us less and that economic activities around the world will become easier again. At the same time, we hope that the bureaucracy will be further reduced and simplified.

In the future, quick decisions will increasingly be necessary and influence our actions. Combicore is ideally equipped for this.

In addition, some investments in new systems and machines are planned for 2022, which will expand and supplement our range of manufacturing. We therefore rely on individually developed solutions that are precisely tailored to our needs.

Now the framework conditions have to be right.