Constantia Flexibles is the world’s third-largest producer of flexible packaging. Based on the guiding principle of ‘People, Passion, Packaging’, some 8,540 employees manufacture tailor-made packaging solutions at 36 sites in 16 countries. Many international companies and local market leaders from the consumer and pharma industries choose our sustainable and innovative products. The Group generates 66% of its total sales revenues in Europe, 17% in the Americas (USA/Mexico), 11% in the Asia-Pacific region, and 6% in the Middle East, Africa, and Australia.

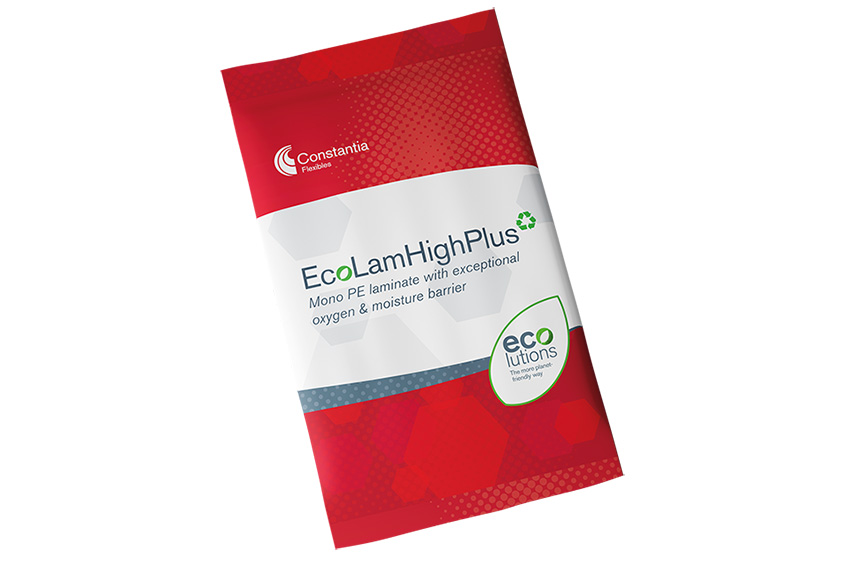

Constantia Flexibles produces a wide range of products based on aluminum and plastic substrates and is a global leader with several product lines, including confectionery packaging, lids for dairy products, and aluminum container systems for food and pet food products. The company is the world’s leading supplier of blister foils and cold-form foils. Constantia Flexibles is fully committed to Circular Economy with their recyclable product range Ecolutions. The packaging line Ecolutions meets sustainable requirements, reduces the carbon footprint of packaging, focuses on recyclable solutions, and decreases the impact on the environment. In addition to the sustainable characteristics, the packaging solutions have all the properties required to protect the packaged products.

Easy Engineering: What are the main areas of activity of the company?

CONSTANTIA FLEXIBLES: Constantia Flexibles has two business segments: Consumers & Pharma. Consumer division is about three-quarters of our company’s business. For both segments, we offer aluminum-based (55%), film-based (43%) and paper-based (2%) solutions.

E E: What’s the news for 2021 about new products?

CONSTANTIA FLEXIBLES: Our latest innovation is called Perpetua. It is the company’s first recyclable polymeric mono-material, has a wide range of uses in pharma packaging applications, and is available worldwide. Perpetua offers excellent product protection from oxygen, water vapor, and light.

High protection levels against moisture, oxygen, and heat are important for protecting active pharmaceutical ingredients (APIs) to provide effective medication. Our goal was to meet pharma products’ very high barrier properties while implementing the best possible sustainability standards. The result is Perpetua, a recyclable product family based on a unique line of full PP (Polypropylene) high barrier laminates. The flexible packaging solution is available in application-tailored versions. Being cyclos-HTP certified, its recyclability ranges from 90% to 96%, depending on the individual material specification. The high barrier properties and lower environmental footprint do not limit the design possibilities of the packaging.

E.E: What are the ranges of products?

CONSTANTIA FLEXIBLES: Our portfolio is broad. In the Consumer division, we provide applications for beverages, confectionery, dairy, home & personal care, meat & fish, pet care, processed food, snacks, as well as technical films and foils. And as well our packaging line Ecolutions.

Our Pharma division offers applications for injectable drug delivery, medical devices, oral drug delivery, pulmonary drug delivery, or transmucosal/transdermal drug delivery. Its packaging forms range from blister to container, sachet, stick packs, to name a few. Constantia Flexibles’ solutions include blister lidding foil, coldform foil, laminates, and technical services.

E.E: At what stage is the market where you are currently active?

CONSTANTIA FLEXIBLES: The global market for flexible packaging grew by an estimated 3.2% globally in 2020 (in volume terms), 2,5% in Europe and nearly 7% in North America, retail consumption being boosted by a decline of ~30% in the foodservice sector, and that led end-consumers to stock up. Prior to COVID-19 wave 2, Euromonitor was forecasting flexible packaging demand to return to normal levels by the end of 2021. These assumptions are under further review in light of the most recent development of the pandemic.

E.E: What can you tell us about market trends?

CONSTANTIA FLEXIBLES: Constantia Flexibles operates in the flexible packaging market, which is largely unaffected by cyclical fluctuations. The long-term growth factors stem from global megatrends as well as a general shift from rigid packaging to flexible packaging solutions. These megatrends include urbanization, sustainability, healthcare, and the broadening of the middle class.

Constantia Flexibles is likely to benefit from opportunities arising from new middle classes in emerging markets. The rising standard of living is driving the demand for our solutions, especially in the food, pet food, and pharmaceutical industries. Additional opportunities will arise from demographic developments such as rising life expectancy and the trend towards smaller households. Constantia Flexibles is well-positioned to meet the ever-increasing demand for greater product variety and better product quality.

E.E: What are the most innovative products marketed?

CONSTANTIA FLEXIBLES: Our more sustainable product line is Ecolutions with products like EcoLam, EcoLamHighPlus, EcoPaperPlus, EcoVer, EcoAluTrainer, and ComfoLid, only to mention a few. The products cover a wide range of applications and allow our customers to switch to a more sustainable and recyclable solution for their products. Sustainability is an integral part of all business activities. We rethink packaging every day to make a meaningful contribution to our customers and the environment. We have one big goal: We pledge that 100% of our packaging will be recyclable by 2025.

E.E: What estimations do you have for 2021?

CONSTANTIA FLEXIBLES: The packaging industry is expected to continue to grow in 2021 with higher growth rates in emerging markets and a revival of more mature markets such as Europe and North America:

- Europe: 1-2%;

- North America: 3-4%;

- South America: 1%;

- India: 7-8%;

- Africa: 3-4%;

- South East Asia: 6%.

We expect the lingering impacts of the COVID-19 pandemic to continue to impact certain market segments, particularly the „food-to-go” markets that have been adversely affected by lockdowns across the globe.