Coval Technologies invented and now manufactures a range of high-performance nano coatings in Singapore and Houston, Texas. The coatings are all thin film, extremely hard and have excellent stain and chemical resistance. What makes our technology truly unique is how it bonds to almost any surface.

Coval coatings have millions of active molecules per sq.mm that chemically (covalently) bond to the substrate which gives it superior adhesion. This also means that Coval coatings do not require aggressive surface preparation that mechanically bonded coatings do, and this is a huge cost savings!

The single component, UV stable coatings form a long-lasting barrier against food, drink and other stains, scratches, and weathering. Coval is often used over other coatings such as epoxies and urethanes and even paint to extend the life cycle by stopping UV oxidation. Coval Technologies aims to reduce the environmental impact of the coatings industry by decreasing installation and maintenance time while eliminating harsh cleaning chemicals and protecting the built environment.

Interview with Ryan Crowe, Founder & Managing Director of Coval.

Easy Engineering: What are the main areas of activity of the company?

Ryan Crowe: Coval Technologies is constantly investing in R&D to develop solutions to issues where other coatings technology has not been able to find adequate answers. The products are marketed to and used on a multitude of surfaces: flooring – including concrete, epoxy, vinyl tile, linoleum and polished concrete; on metal artwork, cranes, pipelines and bare stainless steel and aluminum; on fiberglass boats and other recreational vehicles, and on concrete and stone infrastructure. All are graffiti resistant.

E.E: What’s the news about new products?

R.C: Coval Technologies introduces Coval Polished Concrete Sealer, a product that won’t change the natural beauty of polished concrete while protecting the surface. Coval’s product is an alternative to a traditional guard, a thick coating that takes away from the “look” of polished concrete and creates a costly maintenance loop involving burnishing and reapplication of the guard.

Polished concrete floor owners often take their chances with potential stains by not applying a coating and then have stains in the porous concrete. Coval’s solution: Coval Polished Concrete Sealer is single component and UV stable, with easy application and cleaning once installed. It will last two to four years or more, and bonds to itself.

E.E: What are the ranges of products?

R.C: Coval has 6 products globally, and another offered in the second quarter 2023.

Coval Ultimate Top Coat protects and enhances many surfaces including epoxy, terrazzo, polished and stained concrete, signage, walls, and infrastructure, painted or unpainted.

Coval Vinyl provides a durable layer of protection from scuffs, stains, and graffiti to reduce the maintenance costs of Vinyl Composite Tile, Luxury Vinyl Tile and other vinyl laminate floors.

Coval Concrete extends the life of flooring or infrastructure. The covalent bond enhances the natural beauty of brick, stone, and pavers, and can be applied to plain or decorative concrete. Its reduction of concrete dust and resistance to abrasion and graffiti lowers maintenance and replacement costs, even in high traffic areas. Coval Primer is applied before Coval Concrete and may have dye added to it.

Coval Polished Concrete Sealer penetrates concrete pores without changing its natural beauty while protecting it from stains, acids, and oils. It will be available in the second quarter 2023.

Coval Metal resists UV oxidation and corrosion with a superior coating barrier, adhering to painted metal, and bare stainless steel and aluminum. It protects surfaces from oxidation, corrosion, and graffiti.

Coval Marine protects saltwater-based equipment against corrosion, staining, salt spray, and UV oxidation. Applied over existing paints on cranes and to above water fiberglass gelcoat on marine craft, it improves and retains the paint color. Coval continues to expand its technology exploration to protect water vessels from fouling.

E.E: At what stage is the market where you are currently active?

R.C: After spending 14 months on R&D improving the coating technology, we re-launched in May of 2021 targeting the protective flooring market. We are pioneering the protection of substrates by providing a long-lasting solution, quite different from any other coating available in the world. Coval has clients in the United States, Puerto Rico, Canada, Mexico, Singapore, and regions of South America, Europe, Africa, the Middle East and Southeast Asia.

A primary act to drastically reduce the carbon intensity of construction and remodeling is to protect substrates and extend their lifetimes. Coval products provide an oxidation stable protective coating, critical in any strategy to reduce embodied emissions of construction.

E.E: What can you tell us about market trends?

R.C: As the world demands more “green” products, Coval coatings are sustainable. The energy required to produce the coatings, apply them, and clean the substrate once installed is significantly less than many types of coatings available.

The nanotechnology aspect of Coval coatings, using tiny nanoparticles to react with the surfaces to which they are applied, is what makes them different. This allows a facility to easily clean its floors and walls with less labor time, electricity, and no more harsh chemicals. Cities, school districts, home and business developments can save money as well as retail stores, restaurants, and warehouses.

E.E: What are the most innovative products marketed?

R.C: Coval is in the final stages of testing a new Polished Concrete Sealer, in demand by the industry. The penetrating sealer is used on polished concrete and is almost invisible but offers the same stain resistance as our other coatings. It replaces a guard, which does not stop stains, looks artificial, and requires constant maintenance and replacement. Coval Polished Concrete Sealer is a solution for sealing with transparency and little aftercare.

We are also working hard on our Marine Top Side coating. It is easily hand applied with a microfiber cloth to fiberglass and stainless steel on the top side of a boat or yacht to make it easy to clean. It prevents staining from bird droppings and exhaust fumes and lasts several years.

Coval’s next most innovative product is coating pre-existing internal gas and water pipelines. This is done by cleaning out the line and then placing our coating between two specifically designed cylindrical squeegees known as “PIGS”. The coating will bond to the internal pipeline walls as it is pushed down the pipeline by compressed air. The goal is to smooth the wall texture and therefore reduce the energy required to move water or gas down the line. We have seen energy reduction of up to 35% on several lines.

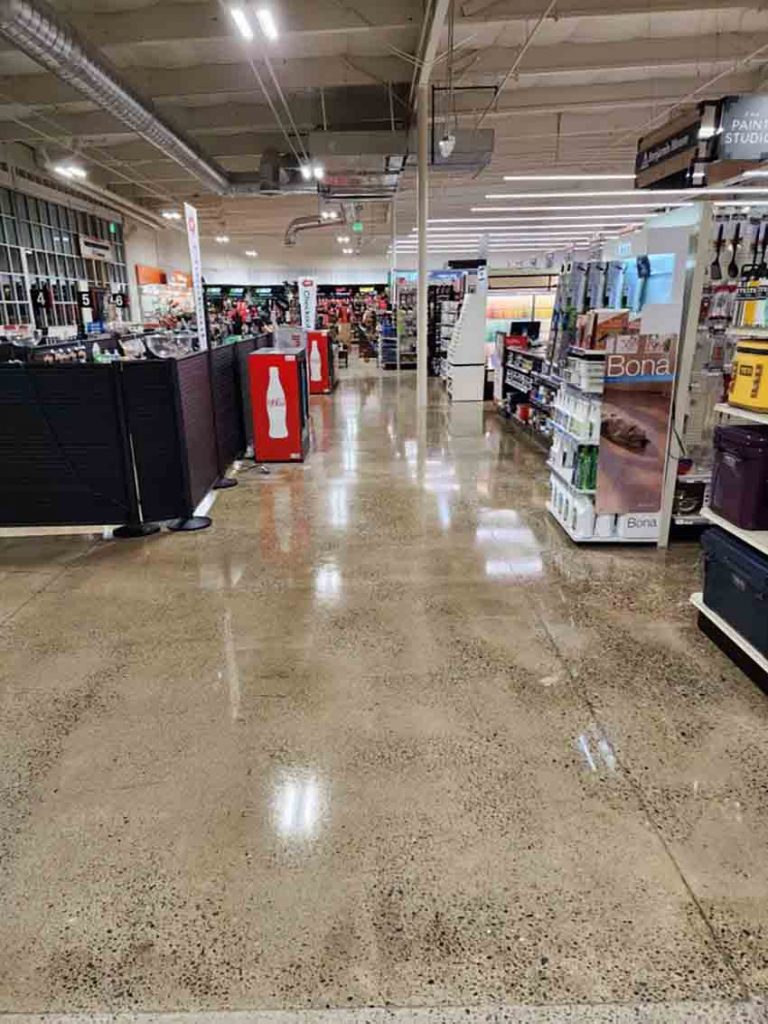

Coval Concrete over Coval Primer on a hardware store floor.

E.E: What estimations do you have for 2023?

R.C: Coval is growing exponentially across the world, and we fully expect this trend to continue throughout 2023 and beyond. The range of applications are enormous, and we are finding new applications for our technology every day. For example, we were recently contact by a EDPM installation company who asked if our coating could coat EDPM rubber. We tested it and not only does Coval outperform the urethane they were using; it is cheaper and easier to apply. When tested on 10-year-old, sun-drenched, faded, oxidized EDPM rubber, it was revitalized to make it look like new.

Since we find new applications for our technology frequently, it is difficult to run estimations on growth other than by saying we are highly confident that we are moving in the right direction!

In addition, the sustainability of our products is noted in the easy to apply nature of “just spray and walk awayTM,” leading to additional sales to companies interested in sustainability.

Coval will continue to listen to its clients; distributors, municipalities, developers, architects, and installers to provide new, innovative products needed to protect a variety of substrates worldwide.