Critical Manufacturing is an innovator in Manufacturing Execution Systems (MES). Since its foundation 12 years ago, its vision, strategic objectives and goals are all focused on providing the most modern, comprehensive and modular MES solution in the market for manufacturing companies. The software they provide helps their customers achieve greater efficiency, productivity, quality, and agility – and, as such, competitive edge.

Highly flexible and adaptable, their MES is designed with the advanced capabilities and functionality required to handle the complex manufacturing processes for high-tech products. The company supports the Critical Manufacturing MES with modelling, engineering, configuration, project management, installation and aftermarket services to deliver and maintain a highly efficient and effective manufacturing solution.

Interview with Augusto Vilarinho, Business Development Director, Critical Manufacturing.

Easy Engineering: What are the main areas of activity of the company?

Augusto Vilarinho: Built around the needs of manufacturing, Critical Manufacturing’s MES is a state-of-the-art solution based on a unified architecture, provides a complete set of integrated modules. It meets diverse needs through a wide range of functional blocks that compose the MES platform. Key markets are high-tech industries, including electronics, semiconductors, medical devices and complex discrete manufacturing. Our solutions are designed to help manufacturers progressively increase automation levels of factories, provide a pathway to Industry 4.0 and rapidly scale across multiple sites located anywhere in the world.

E.E: What’s the news for 2021 about new products?

A.V: Based on our continuous engagement with customers, Critical Manufacturing is constantly investing in its solutions. This permanent investment ensures a consistent release of new features and modules, more and better functionality, and the incorporation of latest Industry 4.0 technologies.

Specifically, for 2021, we will solidify the advanced capabilities we offer to semiconductor and electronics manufacturers, ensuring we exceed standards and provide the leading MES solution for these segments. We will also continue to invest in our ground-breaking IoT Data Platform, which integrates advanced data ingestion and processing capabilities with cutting-edge MES functionality. Our customers in other business segments will also take advantage of these new additions, together with several enhancements which reflect the voice of the customer in our roadmap.

E.E: What are the ranges of products?

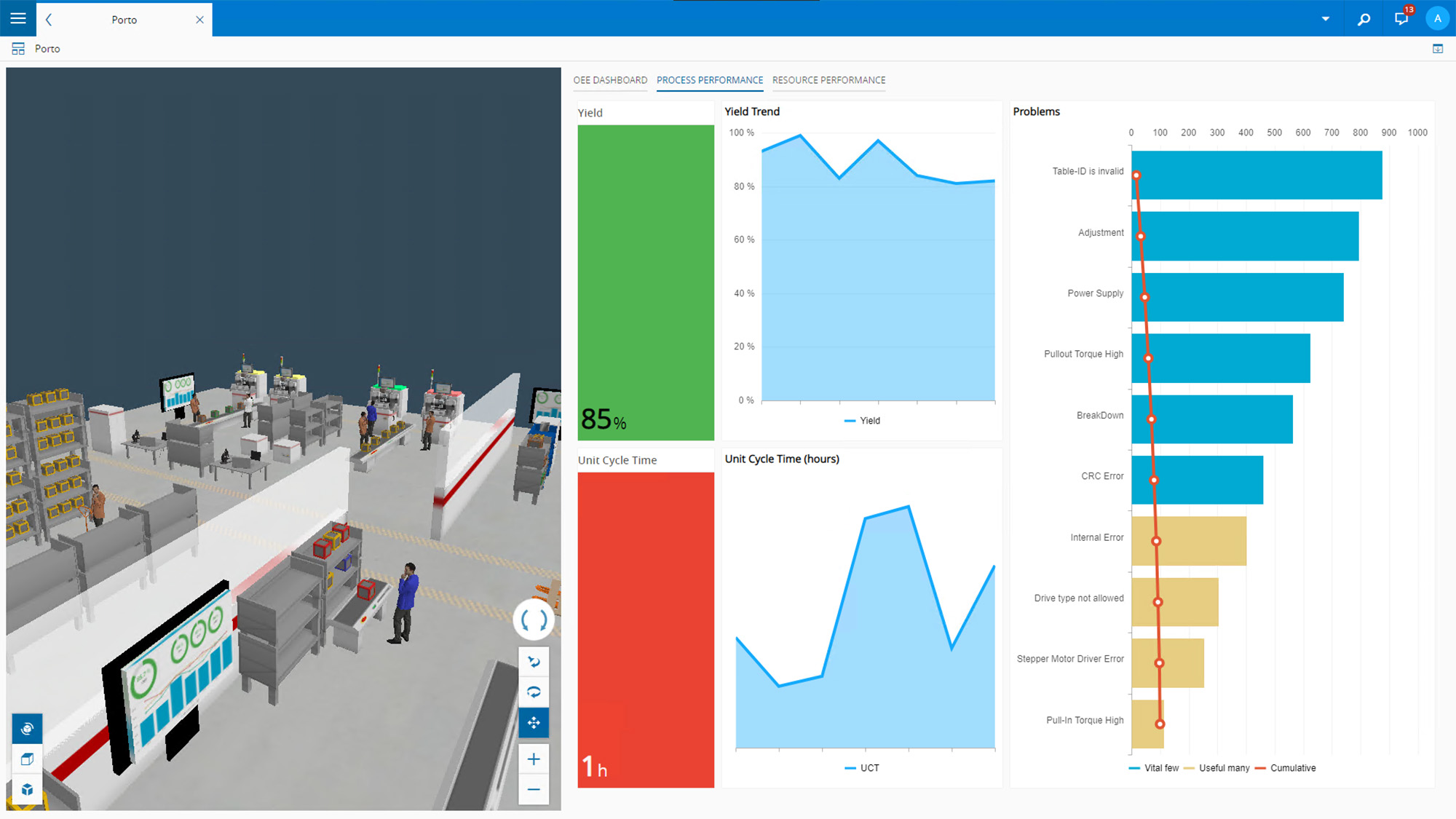

A.V: With our focus on manufacturing operations management, our products are built around the concept of a digital factory. They not only include traceability and visibility, but all pieces and components of the manufacturing process, including management of materials, quality, engineering and labour. Our platform provides real-time control and visibility, using data from humans, machines and processes to leverage process capabilities. By managing human resources as well as machines and devices, the system can not only optimize the processes themselves, but all activities, such as maintenance, advanced scheduling, and the availability of certified operators to carry out tasks, to ensure quality, efficiency and optimized utilization of all assets. Information is mapped in a digital system, which uses advanced capabilities to enable the highest level of optimization and deeper insights into processes.

E.E: At what stage is the market where you are currently active?

A.V: Different market segments have different levels of maturity and needs in terms of digitalization. There are also different levels of perception of what a digital system should be, with some already having several years of capital investment in digital systems and others requiring additional contextualization of the benefits. Critical Manufacturing has experience in multiple areas of manufacturing with varying levels of maturity, enabling us to help customers at any stage of the journey to digitalization.

E.E: What can you tell us about market trends?

A.V: Organizations are evolving in terms of digital maturity and there is a growing perception, even in sectors that are traditionally conservative, that digitalization is essential to remain competitive into the future. For all the problems and tragedy caused by the pandemic, the effect of global lockdowns has elevated the awareness of the benefits of greater automation, leading to the opinion that if some businesses had invested more in digital solutions, they would have had greater resilience during this difficult time and be in a more competitive position for the future. Almost every company now has digital initiatives which are only being accelerated due to the pandemic.

We see organizations investing more in higher automation, which is very much a combination of hardware and software. This is a move away from just investing in sensors, tools or machines with a greater understanding that the software and hardware go hand in hand.

The other trend is the need to absorb exponentially increasing volumes of data. This data not only needs to be ingested and stored, but also processed using advanced analytical algorithms to derive deeper insights into processes, support strategic decision making and enable greater optimization. To achieve this, all areas of systems and data need to be brought together and, once processed, data needs to be fed back into operations to close the loop for continuous improvement.

E.E: What are the most innovative products marketed?

A.V: The innovation in Critical Manufacturing’s MES comes from the entirety of the solution. It provides rich features and modules to monitor, control and optimize operations on top of the latest technology platforms. The resulting solution is a combination of MES, IOT and automation with a high performing data platform.

The Critical Manufacturing MES is designed to adapt with future developments. We are constantly and heavily investing in product development, keeping the solution ‘on top of the wave’ and absorbing the latest processing trends and technology. In this way, innovation is applied in every aspect of our solution – including functionally, technically, architecturally and from useability perspective.

E.E: What estimations do you have for 2021?

A.V: We have experienced significant growth and anticipate this continuing at a fast pace through 2021 with ambitious growth targets. We will solidify our plans to grow organically and, following being named as a leader in the 2021 Gartner Magic Quadrant for Manufacturing Execution Systems report, secure our position as one of the highest-ranked MES providers.

contact@criticalmanufacturing.com