CROMA has been a French manufacturer of hot wire cutting systems for almost 40 years. Pioneer on the market, the company has sold over 2000 machines in 70 countries.

Easy Engineering: What are the main areas of activity of the company?

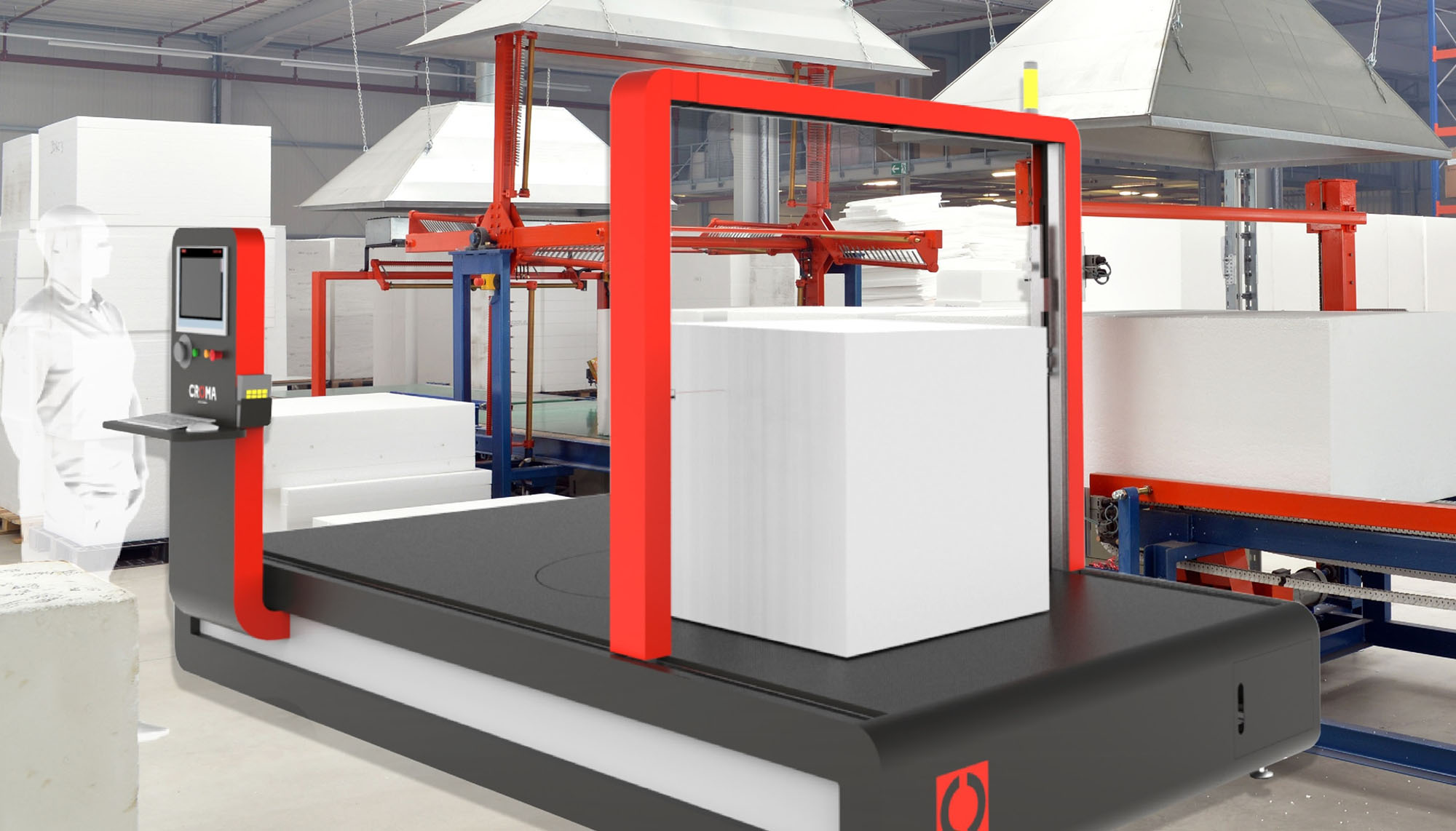

CROMA: Our machines mainly process foams such as EPS, XPS, EPP, PE, Bultex, PU. They are used in the building trades, events and signage, and many other industries. Our systems can be used on construction sites or road building and our computer controlled machines operate in small to large workshops such as precast concrete factories, design and prototyping specialists, furniture manufacturers.

E.E: What’s the news about new products?

CROMA: This year, CROMA introduces its new TOMI CNC range with a heavy steel and aluminum frame and worm gear guides. It also has built in features such as the wire breaking detection, speed variation, wire extension… This innovation is a very versatile machine that suits most of our customers with a limited footprint and excellent quality-price.

E.E: What are the ranges of products?

CROMA: Our ranges start with the manual cutting tools to the most complex industrial CNC cutting line. We have the best equipment for any type of customer, from the small craftsman to the largest multinational.

We also provide custom made systems to best meet our customers’ requirements. Downcutters, conveying systems, cutting lines dedicated to mortises… all types of automated systems can be developed by CROMA in collaboration with our customers team.

We have also developed a coating machine and accessories for cornices or panels covering and a Grinder Compactor to recycle EPS and XPS so that one can earn money from his wastes.

E.E: At what stage is the market where you are currently active?

CROMA: Our market is a niche. CROMA is well known and has an excellent brand image thanks to high quality products and services. Our software is the best on the market and we still support customers with machines that are over 20 years old. With a new management team since 2019, CROMA also renewed its identity to show this new dynamic and initiated a continuous improvement process to stay at the forefront of progress.

E.E: What can you tell us about market trends?

CROMA: Due to environmental concerns the market is changing. There is not many EPS in the packaging field anymore, for example. Nevertheless, construction and builders are still using a lot of this material and it is our job to adapt our offer to the current needs. The machine sizes have also evolved to fit the new block standards, of 6 meters long or even 8 meters in the USA. Now our range offers standard machines up to 6 meters by 6 meters.

There are also new foams coming on the market all the time. We have to test them and come up with the right solutions for our customers to process those.

E.E: What are the most innovative products marketed?

CROMA: The TOMI series is the most innovative because it can suit any type of industry and carry out large productions, with an optional 20-wire cutting mode, as well as very sophisticated 3D models, with the wire extension and the exclusive Stratoconcept software.

E.E: What estimations do you have for 2023?

CROMA: The Middle East seems to be the most active market today and we hope to increase our market shares there through active partnerships in UAE and Saudi Arabia. We have also found new distributors to cover the Americas and are looking for more partnerships worldwide.

Our sales of grinder compactors have increased 4 times over the past 3 years due to environmental policies and the increasing material value. We aim to maintain this level for the next 5 years.