DEVELOP LLC’s engineers, manufacturing experts, and project managers specialize in automation integration and industrial hardware. Since 2015, this Verona Wisconsin based innovator has built a reputation for solving industrial automation problems ranging from product quality issues, floor safety, capacity limitations, consistent output, labor shortages, excessive expenses, and production bottlenecks with custom robotics integration and engineering services. When customers need custom or semi-custom industrial hardware for automation equipment and off-highway machines from an Original Equipment Manufacturer (OEM), they come to DEVELOP LLC.

Interview with Matt Moseman, President of DEVELOP LLC.

Easy Engineering: What are the main areas of activity of the company?

Matt Moseman: Whether you are a first time automator or an industrial automation veteran, you need experienced experts adept at growing client businesses through high-efficiency automations. From concept to completion, DEVELOP LLC covers 360° of the integration process, backing results with a proprietary single-source guarantee. In turn, customers can focus less on repetitive tasks and more on the profitable aspects of their business.

We educate our clients beyond what anyone else wants to do. It is time intensive and costly for us to do so, but this is how we’ve built so many long term repeat customers. We train our customers how to maintain and make programming changes to their machines. We prepare customers for rapid fault recovery, increased capacity, and how to reach return on investment as quickly as possible. Our customers more than any other achieve a sense of self reliance, even on their first automation integration.

E.E: What’s the news about new products?

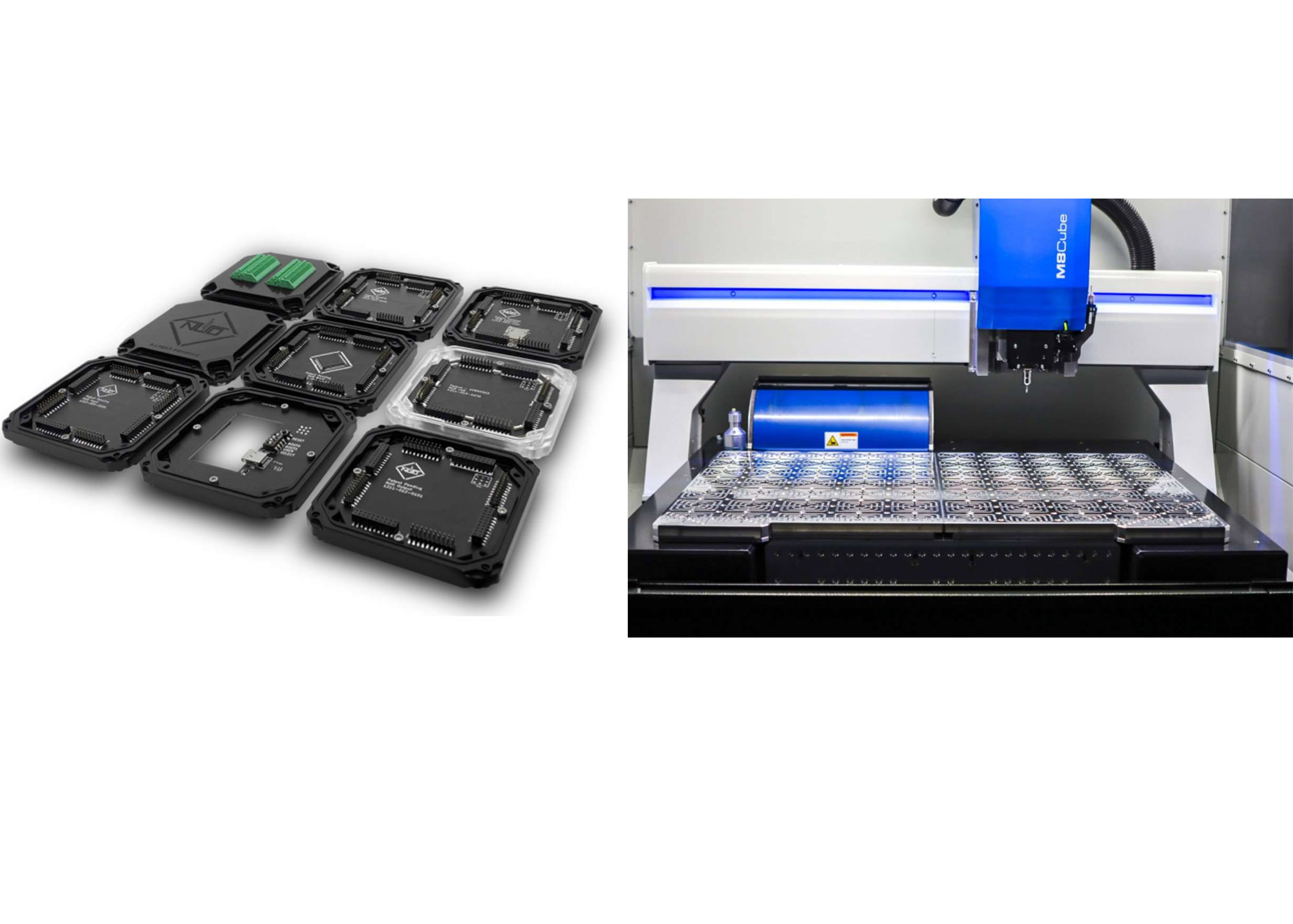

M.M: Our NodeUDesign’s configurable control modules are the ideal choice for any industrial application. With their flexible features and sleek design, you can automate all of your tasks with ease. This Plug and Play solution provide a way to automate industrial systems with programmable logic at the node level. These nodes can be customized with just enough I/O or communication options to fit your requirements without sacrificing future expandability, all in a compact design that reduces installation time when compared against other PLCs & SCADA systems. NodeUDesign’s industrial ecosystem of I/O and communications can be integrated with nearly any existing hardware system with its Python-based logic programming.

We’ve also got a whole new set of innovative accessories for our Vacuum Fixture Plates coming in April 2023. Vacuum Fixture Plates combine the staying power of conventional vacuum plates with the versatility of a fixture plate system. As a result, we facilitate quick part change-outs, all with a simple, low-profile setup.

E.E: What are the ranges of products?

M.M: DEVELOP LLC maintains a single source single point of contact guarantee from concept to completion. We own every aspect of the automation integration process including mechanical engineering, electrical engineering, software and robotic programming, firmware engineering, and custom hardware. We integrate turnkey automation systems, pick and place robotics, packaging and palletizing robots, linear transfer CNC machines, adhesive dispensing systems, and custom robotics integrations.

Before any project starts, we provide an automation assessment. Responsible integration relies on a plan for swift return on investment, user adoption from the CEO to the machine tender, definitions of success, definitions of failure, understanding the unique business needs of the individual customer, and an understanding of how to mitigate the risks of investing in automation. Our assessments provide data driven proof of concept strategies to increase capacity while mitigating risks.

E.E: At what stage is the market where you are currently active?

M.M: DEVELOP LLC is most active in the lower 48 states in the U.S. but we’ve shipped custom parts as far as Switzerland and Taiwan. Industrial automation integration is growing at a rapid pace, and we only foresee higher and higher growth. Demand has gotten so high we’ve repeatedly seen customers already using another integrator, perfectly happy with the quality of the previous integrator, but they’ve outgrown the capacity of the previous integrator and need us to step in.

We’ve seen growth every quarter in automation during a recession. Our market is awakening to return on investment averaging less than two years when partnering with an automation integrator. We have a strong reputation with our customers for going above and beyond other automation integrators in educating, explaining options, and targeting the unique pain points of their production.

E.E: What can you tell us about market trends?

M.M: The demand for automated robotic integrators has started to graduate from a competitive advantage to a requirement for staying competitive. It is impossible to ignore the manufacturing labour shortage hitting the market worldwide. Companies are looking for solutions that can bulwark against global market supply chain issues, manufacturing bottlenecks, and economic recession. The technology in automated robotics has advanced to the point where automation can be simpler to manage than manual machine tending, cheap enough for first time automators, and nimble enough to meet the needs of smaller companies.

E.E: What are the most innovative products marketed?

M.M: Real innovation comes from products that lower the barriers of entry and even the playing field.

Our NodeUDesign is a perfect example of a Python language product that lowers the barrier of entry for new businesses to adopt automation and responsibly integrate industrial automation. Millions of users know Python, it is the fastest growing secondary language on the planet. Python programming language is taught in high schools, tech schools, and colleges. It’s used by small businesses, tech giants, and it’s free to download. Compare that to an older language like Ladder Logic, which is primarily limited to tech schools, or buying proprietary languages from the PLC company you’re deploying. By using Python, we’re giving our customers more freedom in who they hire and how quickly they can scale their business.

If your business is looking to make the upfront capital expenditure on automation integration, you have a fiduciary responsibility to partner with an automation integrator like DEVELOP LLC that knows how to look forward.

E.E: What estimations do you have for 2023?

M.M: The industry is going to see a standard trend of first-time adopters of automation. The need for expert automation integrators to maximize the earning, scalability, and capacity potential of turnkey automation, custom robotics, pick and place machinery, machine design, and linear transfer CNC machines is a condition of adopting industrial automation, not an option.

DEVELOP LLC’s expert automation integration team has perfected experience driven scoping of services with tangible results. We acquired an 18,000 square foot facility in 2022 in anticipation of 100% growth.