Dimensionics is an established partner in the fields of automation, as well as measurement & testing technology since its foundation in 2010.

The team of engineers, developers & programmers develops and manufactures customized systems from simple handheld devices to complete production line integrations.

In addition to the above-mentioned special machines & special solutions, Dimensionics offers a selection of individually configurable standard systems.

Dimensionics’ fields of activity include:

- Development in the fields of special machines, metrological concepts as well as individual automation concepts

- Consulting for the design of processes

- Services (process optimization & validation, measuring equipment capability testing, etc.)

Interview with Jan Wenzel, CEO of Dimensionics GmbH.

Easy Engineering: Which are the most innovative products / services and what special features do they have?

Jan Wenzel: Dimensionics specializes in the development of customized metrology systems and process automation, so we can say that each product that we develop is unique, even our standard systems – because they are being optimized to meet the specific needs of each customer. We are experts in fields of tactile and optical metrology, industrial camera systems, weighing technology and density determination, as well as automation. Our DISIONIC line of products stands for flexibility and high quality. Each of these machines meets the highest standard of the Dimensionics company which is also reflected in the positive feedback of our customers.

The most innovative product is our Disionic Density machine, the world’s first automated density scale which combines the Archimedean principle with modern automation technology.

In addition to special engineering as per customer specificiation we offer our standard solutions which are:

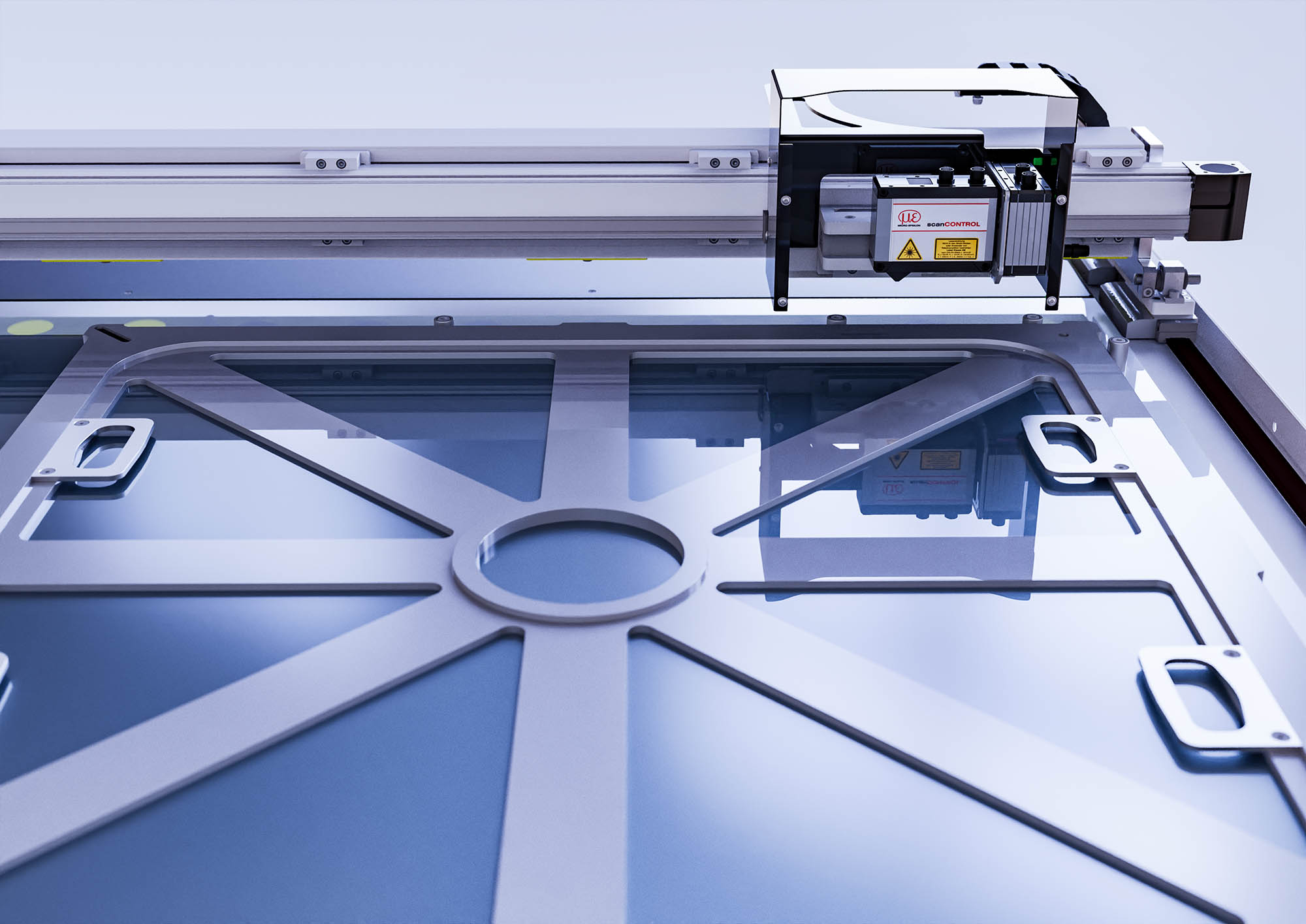

- Disionic Sheet Control – coordinate-measuring table for inspection of metal sheets,

- Disionic Table – Individually configurable workstation systems,

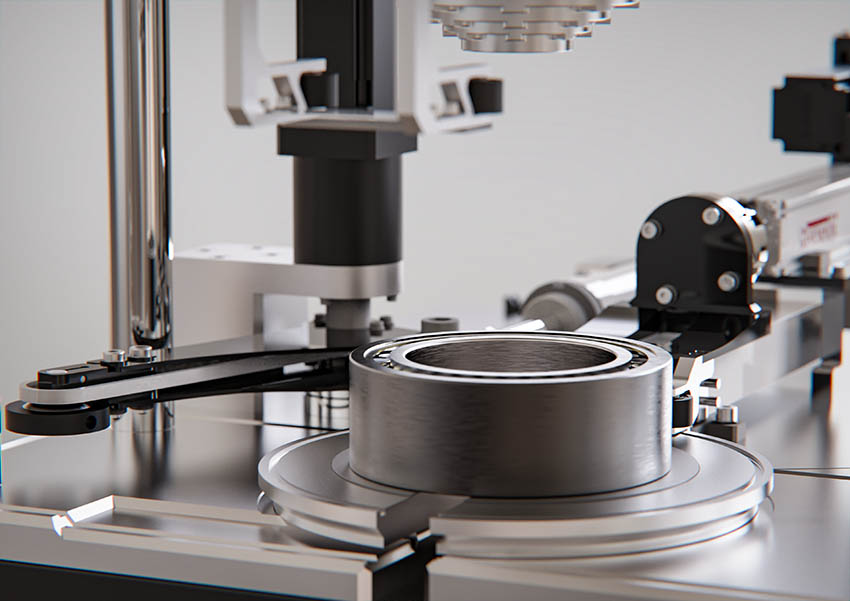

- Disionic Bearing – Fully automated testing of axial-radial bearing clearance for rolling bearings

- Disionic Press – Pressing of various types of components onto PCB during PCB assembly with different and defined pressing forces; monitoring of components for position, location and presence; communication with ERP system

- Disionic Wiring Guide – Assistance system for manual wiring of PCB boards.

- Disionic Precision Lining – device for high-precision positioning of a nozzle in the hazardous area

- Disionic Leak Test – a test bench for the investigation of CNG gas-powered commercial vehicles

- Disionic Projection Welding and Bolting – Fully automated welding, bolting & parts handling; data preparation and -processing incl. communication with ERP system

- Disionic Keg Control – Keg measurement station designed for random inspection; Inspection of up to 16 features per measurement cycle, Development of 4 systems with different conceptions & tasks; Integrated belt infeed & outfeed.

E.E: How important are these features for the users in their work?

J.W: All our standard solutions derive from initial customer projects but are nevertheless suitable and adaptable to a wider field of similar applications. Our customers value our machines for their optimal availability and functionality. We achieve this by respecting each of our customer’s specific requirements in the design of our machines, which results in well running solutions. That sure is the most important feature for all our users.

E.E: How important is innovation in your field?

J.W: Our motto is: “We live the innovation”. We see ourselves as a solution finder and innovation provider. We develop integrated solutions for our customers, from the complex concept to the finished machine. Tailoring is “in the blood” of our specialist teams because every customer, every requirement, every process is different. The fact that we can find an innovative solution to customers complex tasks, is our drive and our mission. As partners, we work closely with our customers. Our teams of specialists analyze, advise, design, develop and implement exactly the solution needed to meet the specific requirements.

E.E: How do your products / solutions impact cost effectiveness for the users?

J.W: Through accelerated manufacturing processes due to a shortened production time, as well as minimization of error sources and reduction of the complaint rate. Additionally, the automation of tedious manual processes allows an efficient utilization of the available workforce and may even safe personnel cost.

E.E: What kind of work do users who use these products / services do?

J.W: Our customers represent a wide variety of industries. As a special engineering company, we don’t limit ourselves to a certain industry or product range. In general, most of our customers have some sort of production process and work in an industrial type of environment to produce their goods. Apart from that we are free to focus our engineering capabilities on whatever challenge reaches us next.

E.E: How do your products increase profitability for users?

J.W: By reduction of downtimes in the production, reduced production time and production errors, our products increase the productivity of companies. By improving the quality of the final products, we ensure that quality costs stay low. And by tracking our results and integrating into company networks we collect valuable data, which results in secure and transparent processes.

E.E: How do your products / services differ from other types on the market?

J.W: All products are dynamically adaptable to customer processes and production and are scalable to the specific requirements. This degree of flexibility enables our products to be used successfully across all industries. All systems are already in use in a wide variety of industries and convey the quality and reliability, for which DIMENSIONICS stands. We offer quality, reliability, innovation and flexibility to our customers.

E.E: What products / solutions are you going to launch in the future?

J.W: We already have quite a range of standard solutions available. In most cases we started off with a special engineering task in a single project. When the solution is in place, we often realize that a similar type of solution could be applicable to other industries and markets as well. So, we develop a suitable standard solution to improve other processes as well. But we can’t know what the future holds yet and currently we

Mail: jan.wenzel@dimensionics.de

Web: https://www.dimensionics.de/

Tel.: +49 176 72887395