Dimensionics Density GmbH was founded in 2020 emerging from its parent company – Dimensionics GmbH’s project on developing and patenting an automated metrological system for the rapid and highly accurate density determination of components of all kinds.

Since then, Dimensionics Density specializes in design and manufacturing of automated machines solely for density measurement, whereas the parent company offers a wide range of customized special machines and solutions, metrological concepts, as well as automation concepts for customers in all industry fields. Dimensionics Density’s focus is on one machine concept that can be further adapted to specific customer needs which is enabled by the in-depth engineering know-how of the parent company.

Interview with Philipp Pruesse, Head of Sales at Dimensionics Density GmbH.

Easy Engineering: What are the main areas of activity of the company?

Philipp Pruesse: We promote and sell the innovative machine for automated density measurement as well as design and adapt it to customer requirements.

We offer testing and commissioned density measurements for our customers from various branches and, of course, we build and deliver our product and provide its maintenance.

E.E: What’s the news about new products?

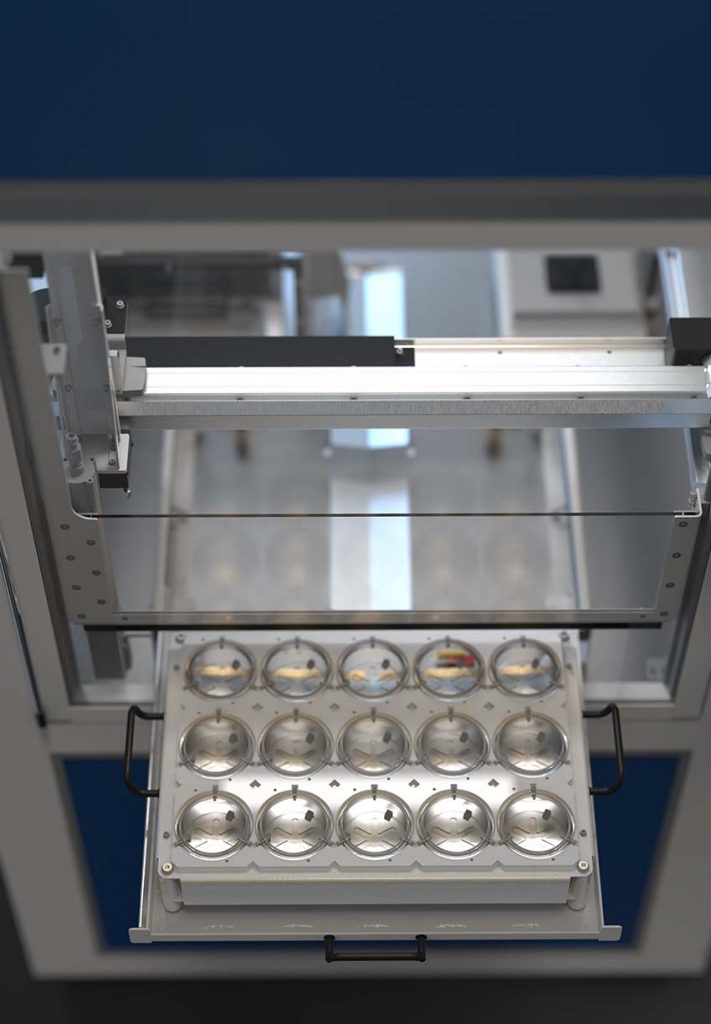

P.P: It is the world’s first automated density scale which implements Archimedean principle. This enables unique features such as: quick results – ability to measure very small parts – ability to measure green bodies – high accuracy and repeatability – etc. – and all that directly on a shop floor, within production line. It decreases machine downtime and overall costs in part production and its quality control.

E.E: What are the ranges of products?

P.P: The company produces density measurement machines only, which come in three different sizes. Each machine can be individually customized to the customer’s specific needs and to respond effectively to the challenges that our customers face in their process.

E.E: At what stage is the market where you are currently active?

P.P: Since density determination plays a significant role in wide range of markets and products, such as sintering, powder metallurgy, medical technology, ceramics production, additive manufacturing, as well as scientific institutions – these are the markets we adhere to. Most of these markets are constantly expanding which is a result of technology, material and mindset improvements and innovations, especially in the additive manufacturing field. The main challenge is still to introduce our product to a wide range of professionals, because it is brand new. While the Archimedean principle is well known and time-proven, an automated machine that can determine density within two minutes and with an accuracy of 0.001 g/cm³ directly on a shop floor was never seen before yet. However, our hard work and dedication are slowly bearing fruits – our machines are already successfully being used by a worlds renowned supplier of ceramic implants and our next two machines will soon be delivered to our customers in the defense industry sector.

E.E: What can you tell us about market trends?

P.P: General industry trend towards automation and interconnected machinery is significantly growing. Personnel is driving cost and the proneness of humans for error justifies investing in automated metrology solutions. However, many companies in Europe are careful when it comes to investment decisions due to uncertainty in last two years, and the war in Ukraine is creating new challenges. We are still optimistic when it comes to our product because we can offer a unique feature package of accurate results paired with short measurement time. This helps our customers to conserve resources by saving time, personnel and machine downtime through a reliable and secure density measurement.

E.E: What are the most innovative products marketed?

P.P: Disionic Density itself is the biggest innovation that offers numerous advantages compared to other density measurement methods such as gravimetric buoyancy measurement, micrograph analysis, CT examinations or use of gas pycnometers.

Apart from that our parent company Dimensionics serves a large variety of unconventional automation solutions which we developed and applied at a wide range of international customers. Through our yearlong expertise with difficult automation projects that other machine builders might reject at first glance, we have mastered the capability to overcome tough challenges and deliver machines with high availability.

E.E: What estimations do you have for 2022?

P.P: Despite the current situation we expect to see a recovery of our business sector. We are positive that our product has a prosperous future ahead, so we plan to increase our marketing activities to reach a larger customer base worldwide with this innovative solution.

Dimensionics Density GmbH

Philipp Pruesse, Head of Sales at Dimensionics Density GmbH,

+49 176 72887395, philipp.pruesse@dimensionics.de