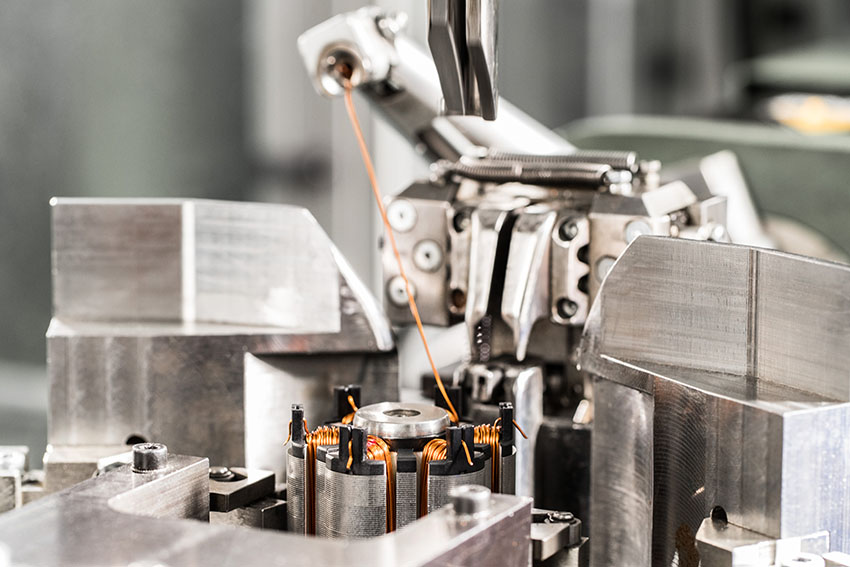

As an innovative and quality-conscious company with about 1,300 employees developing and producing sophisticated linear and rotary motor systems in the middle of the Black Forest in Germany. With 70 years of experience in motor systems, Dunkermotoren knows the requirements of the customer and offers with their product variety high flexibility. Due to their modular system with motor parts with up to 4000 Watts output power and the integration of logic and power electronics, it is possible to create an individual motor solution for the customer’s application. All components of Dunkermotoren’s various innovative motor solutions are designed and produced by the company at Dunkermotoren.

There are not only brushless and brushed motors belonging to the product portfolio but also linear drives, gearboxes, encoders and brakes. The variety of components makes it possible to realize countless combinations within our modular system.

Dunkermotoren – World leader for drives with integrated electronic

In the factory of tomorrow, the boundaries between the technologies and systems of industrial production blur and beyond this, from the field to the enterprise level and out to the end user. Intelligent motors with appropriate Ethernet interface from Dunkermotoren are part of this development which is based on the Internet of things (IoT). The increased networking, the use of cloud-based platforms and the decentralization of computer performance create completely new possibilities for the analysis and utilization of the data provided by the motor and also for the use of the motor itself for autonomously executed tasks. For more than 10 years, Dunkermotoren has been a pioneer in intelligent motors with field bus interfaces and have therefore long been implementing the approaches discussed in the context of industry 4.0 with their customers.

Easy Engineering: What are the main areas of activity of the company?

Dunkermotoren: Dunkermotoren focuses on the following markets: Intralogistics, Robotics, Mechanical and Plant Engineering, Building Automation, Agriculture, Medical Technology and Railway Technology. This gives us a good mix of promising industries and a low dependence on individual applications.

Our strength is to have the complete intelligence integrated into the motor. Nobody integrates its electronics as consistenly as we do. So, our customers can be sure to get a very flexible, compact and high-quality motor solution made in Germany.

E.E: What’s the news for 2020 about new products?

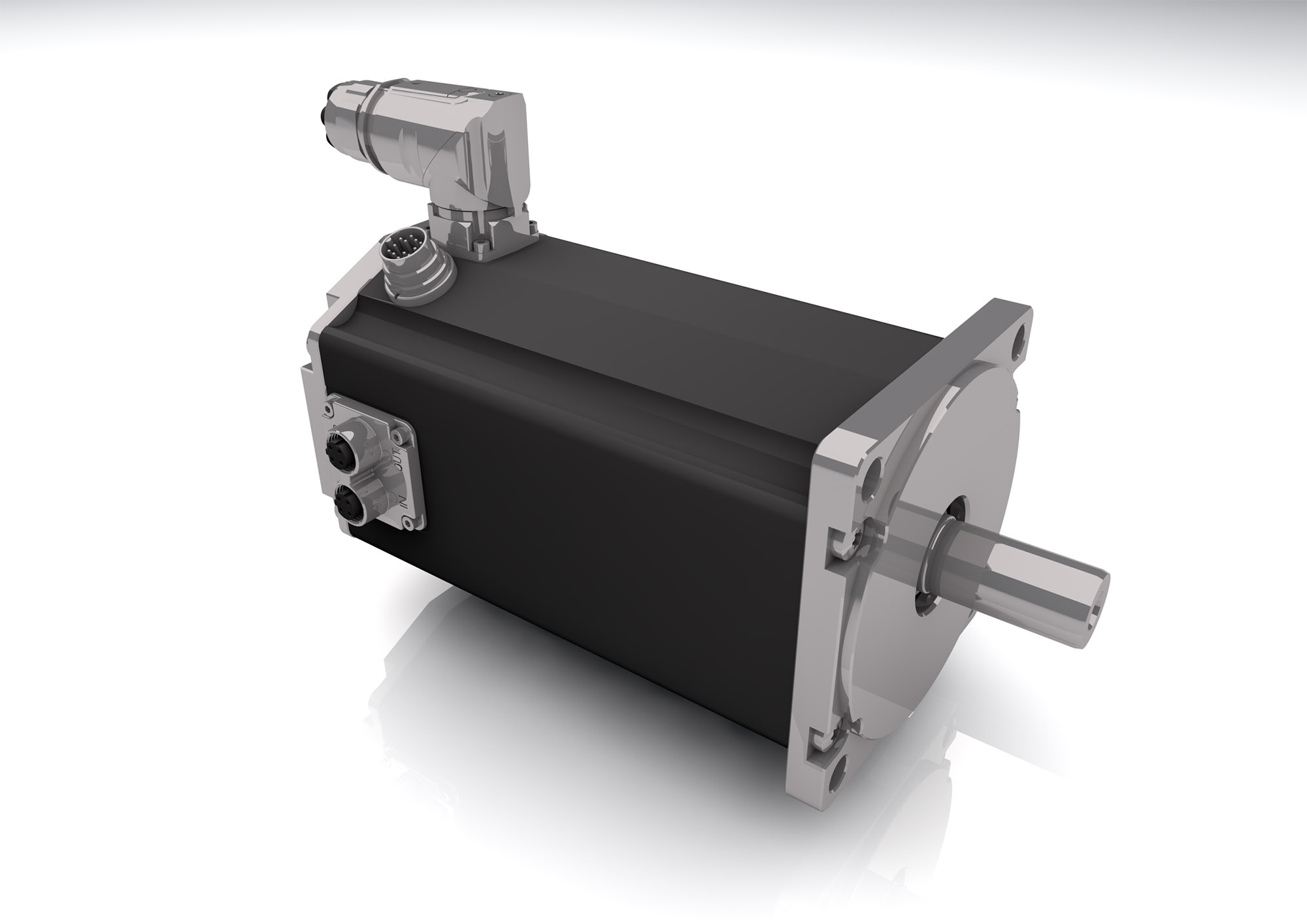

Dunkermotoren: With the BG 95 dPro PN the first motor based on our new Motor Control Platform opens up the Profinet Family. With the BG 66 dPro PN and the BG 75 dPro PN two further products based on the new electronic platform will follow in the same year. The new Motor Control Platform enables more possibilities for our customers e. g. Creation of Motion Apps and Quick Start commands, specific features as Condition Monitoring and an easy integration into the customers application with the Drive Assistant 5 Tool.

Our combination of BLDC motors with the wheel hub gearbox are the perfect motor solution for the intralogistics market especially for AGVs/ AGCs. Our combination of the motor BG 66 dCore, the gearbox NG 250, the brake E 90R, the external controller BGE 5510 dPro and the safety encoder DFS 60S is a very compact solution with a high efficiency. This enables long driving hours without recharging the battery. The BGE 5510 dPro has the important function SafeTorqueOff on board. For higher load, the combination of the BG 95 dPro with the wheel hub gearbox NG 500 is the perfect motor solution. The load capacity of this drive solution is about 500 kg.

With the SA/ SC 38 series, we launched a completely new modular concept for tubular linear direct drives. The modular design is currently available as actuator version SA (with maintenance-free plain bearing system) and component version SC (for modules). If the linear motor should sweat during its efforts, the standard water connection ensures cooling and doubling of the continuous force. One of the main applications of the SA/ SC 38 series will be high-speed applications in the food and packaging industry. Since we have been a system supplier in drive technology for decades, it will not remain just a solo motor. Pick & Place modules, complete linear axes and a version designed for the food industry will soon follow to facilitate system integration at the customer’s site.

E.E: What are the ranges of traded products?

Dunkermotoren: Our product variety offers a power range from 1 to 4,000 W. Due to our modular system we offer over 27 million possible product combinations. With our online configurator you can choose your perfect motor solution online.

E.E: At what stage is the market where you are currently active?

Dunkermotoren: The market focuses on digital solutions for integrating them in their smart factory. Topics such as cloud connection in the context of Industrial Internet of Things (IIoT) shape the discussions.

E.E: What can you tell us about market trends?

Dunkermotoren: A modern drive solution must have decentralized intelligence and sensor technology as well as a communication interface. This is the basis for many possibilities and features, including e. g. Condition Monitoring, Safety Functions, Predictive Maintenance or Vector Control. In addition, “classic” values such as energy efficiency, power density, performance and economy continue to count.

E.E: What are the most innovative products marketed?

Dunkermotoren: In 2016, we launched the BG 95 dCore which is with about 4,000 W the strongest BLDC motor @24 VDC at the market. In the last four years the product family of the BG 95 grew. Today, we can offer our customers the BG 95 dPro based on the new electrical plattform with an integrated CANopen and Profinet interface. The integrated interface for EtherCAT will be launched in the near future.

As before mentioned, the launch of the Motor Control Platform which is the new electronic standard for our servomotors implicates many new features and possibilities for our customers. The process to have all servomotors of our BG series based on this new platform is ongoing.

E.E: What estimations do you have for 2020?

Dunkermotoren: Since 2019, a team at Dunkermotoren has been working exclusively on connecting Dunkermotoren’s servo motors simply and securely to the Internet and, based on this, realizing added-value functionalities. To be able to solve this together with strong partners, Dunkermotoren has also joined the “Open Industry 4.0 Alliance” and “MindSphere World” associations.

In addition, the focus is on growing together with our sister company MAE from Italy. With a total of 1,800 employees, we will then be able to offer our customers stepper motors and blowers in the future.