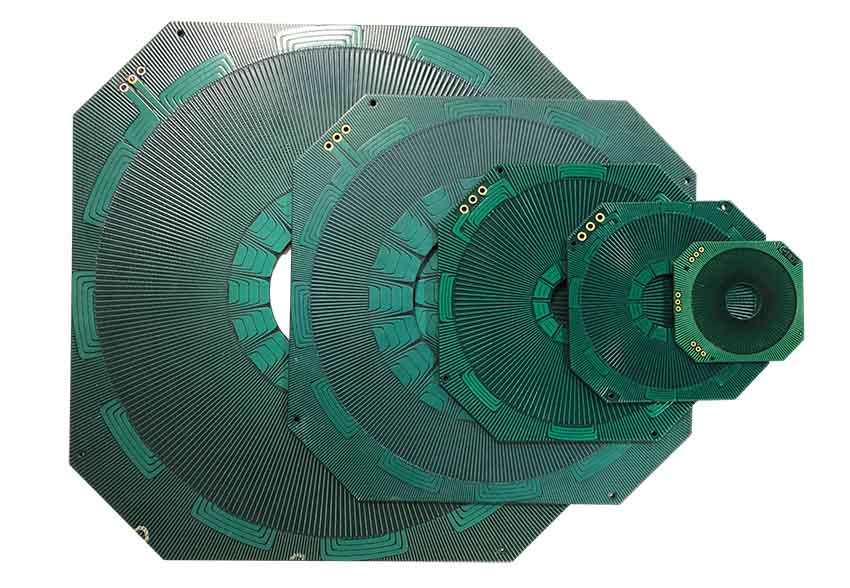

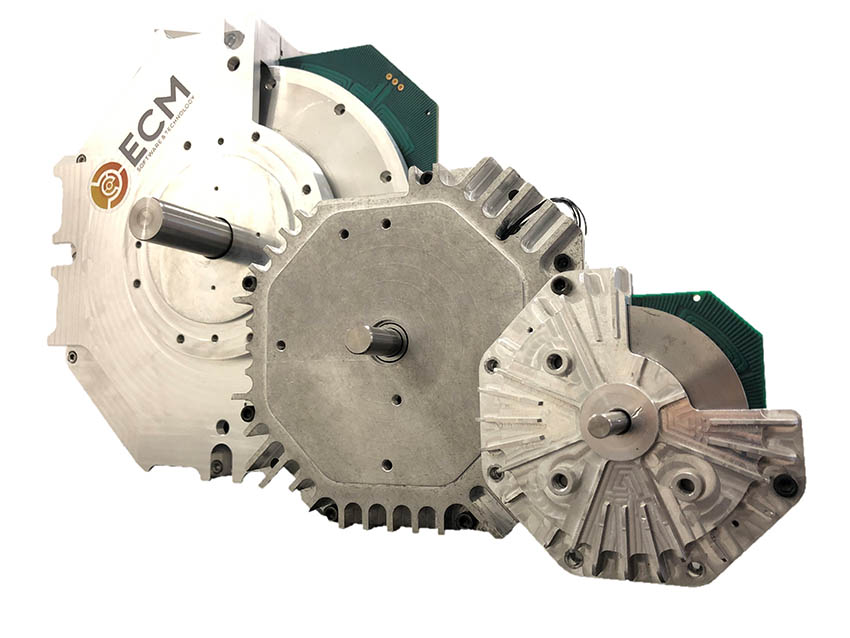

ECM PCB Stator Technology sits at the forefront of electric motor innovation. ECM’s groundbreaking design platform, PrintStator, enables engineers to rapidly design, model and prototype optimized printed-circuit-board stator motors. The resulting PCB stator technology affords highly efficient, lightweight, sustainable, and easily manufactured motor solutions, uniquely optimized to each application.

Interview with Brian Casey, CEO of ECM PCB Stator Technology.

Easy Engineering: Please share a brief description of the company.

Brian Casey: ECM PCB Stator Technology is a US based company behind the next generation of electric motors. ECM’s axial flux motors replace bulky, copper windings with a proprietary PCB stator that offers benefits across a wide range of electric applications. The design customization and ease of manufacturing is made possible through ECM’s PrintStator software.

ECM’s software platform is changing the way engineers interact with electric motors. For each unique application, PrintStator enables rapid design optimization and easily scaled manufacturing processes for completely custom PCB stator motors.

Electric motors are not one size fits all products, but critical system components that should be designed for a perfect fit. We’ve developed ECM’s PrintStator software to make it easy for innovators to design, model, prototype, and manufacture custom built, next generation PCB stator motors that are uniquely optimized to any application.

There are also sustainability benefits to our technology. ECM’s PrintStator platform designs motors that reduce energy waste and require fewer raw materials for a lower environmental impact.

To offer some specifics, PCB Stators only need 20% of the copper found in comparable motors and the PrintStator software designs machines with efficiencies up to 96%. In short, ECM’s PrintStator software creates electric motors that are lighter, faster, quieter, and more energy and design efficient across myriad use cases.

E.E: What are the main areas of activity of the company?

B.C: ECM uses its PrintStator software to optimize PCB stator motor designs for specific applications, ultimately building and testing the first batch of prototypes for our partners to scale and commercialize.

ECM works with a diverse range of actors to create an infinite number of motor designs to serve multiple use-cases and sectors. We’ve used our PrintStator software to design custom motors for corporations, governments, small businesses, gaming companies, innovators, disruptors, and startups—to name a handful.

E.E: What should we look for next from ECM in terms of new product offerings?

B.C: ECM is performing the final round of development and testing before the beta release of its PrintStator design platform. With the PrintStator software in their toolbox, engineers and product innovators will be able to design, prototype and manufacture their own PCB stator motors in house – taking full advantage of the technical and supply chain benefits associated with these advanced motors. The full alpha version of the software is expected to release in Q1 2023.

Additionally, ECM is on the verge of incorporating our PCB stator technology into large-scale production in many sectors of the consumer market. Global market-leaders are prototyping projects with ECM across several consumer industries including gaming, e-mobility, household appliances and residential HVAC products.

E.E: What are the ranges of products?

B.C: Whether improving an existing system or creating something entirely new, ECM has integrated its PCB stator technology into a huge variety of applications across electrified industries. Those include HVAC, consumer electronics, e-mobility, fitness, medical devices, robotics, renewable energy, aerospace, defense, unmanned vehicles, precision motion control, haptic systems, and more.

E.E: At what stage is the market where you are currently active?

B.C: The electric motor industry is an over $100 billion a year market that is expected to double in growth to over $200 billion in less than a decade, as more applications move away from fossil fuel energy sources toward electrification. However, PCB stator motors are a relatively new phenomena within this established industry and are making waves amongst market leaders and innovators.

As mentioned, ECM is active across a wide range of submarkets within the e-motor industry including aerospace and defense, HVAC, consumer products, robotics, medical devices, and haptics and precision motion. The variety of sector verticals also comes with a variety of market stages, with some being well founded and others being more novel products.

E.E: What can you tell us about market trends for your business?

B.C: The electric motor market is expected to grow exponentially driven by three global macro trends: greater electrification (particularly in transit and mobility), significant growth in robotics and automation, and advances in electronics.

Due to a demand for more sustainable applications, the electric motor market is also moving towards higher efficiency motors with a smaller carbon footprint. Several regulatory changes across Europe and the US have further advanced this desire for high-efficiency motors. One example is the increase in minimum efficiency for AC units due to be imposed in the US beginning in 2023.

The end goal for consumer products is always formed around user experience and industry innovators are constantly searching for smaller and lighter motors that offer lower noise pollution.

E.E: What are the most innovative products ECM has designed?

B.C: All ECM’s partners are achieving significant innovation in their products and sectors using next generation PCB stator motors.

One of our projects is headed to the sets of major films. NODO Film Systems recently announced the Inertia Wheels MAX, an upgrade for their popular cinema controller, which leverages printed circuit board stator motors designed with ECM’s PrintStator software. This new product integrates the electric motor deeply into the assembly of the wheel. By combining the pancake formfactor of PCB stator motors with the design flexibility made possible with the PrintStator software, NODO is offering a new wheel design that provides greater precision and three times higher peak motor torque in a smaller package.

E.E: What business growth projections do you have for 2022?

B.C: ECM has seen exponential growth since launching in 2018. We project this will continue through 2022 and beyond.

The advanced technology of PCB stators, coupled with the rapid design and prototyping options enabled by our PrintStator software, have proven particularly desirable—leading to the adoption of ECM’s technology across numerous industries.

ECM estimates further business growth across sectors that have already begun to implement our PCB stator motors. We also expect continued advances of our services into new industries as the benefits of custom designed, perfect fit motors for electric applications are truly understood.

With the release of our PrintStator software in early 2023, ECM anticipates an increased adoption of the technology across an even wider geographical and industry range.