eddylab GmbH is a specialized company, which designs, engineers, and produces sensors for the measurement of distances and positions for more than 20 years. Besides eddylab’s standard products in stock for a plenitude of industrial applications their strength is the development of custom-made sensors.

The company is based in the south of Munich, Germany.

Easy Engineering: What are the main areas of activity of the company?

EDDYLAB: eddylab GmbH offers short term available products for a variety of industrial applications in factory and process automation, test benches as well as research and development. In many cases our products can be configured to meet our customer’s needs: A wide range of technical options ensures that the sensors can be perfectly adapted to different requirements (for example, an increased protection class, an extended temperature range or even the combination of different options).

On the eddylab calibration machines, we can do customer specific calibration regarding measurement range and target materials. In addition, our strength is the development of custom-made sensors. In this context, we realize both individual pieces as well as medium and large series for OEM integration.

E.E: What’s the news for 2021 about new products?

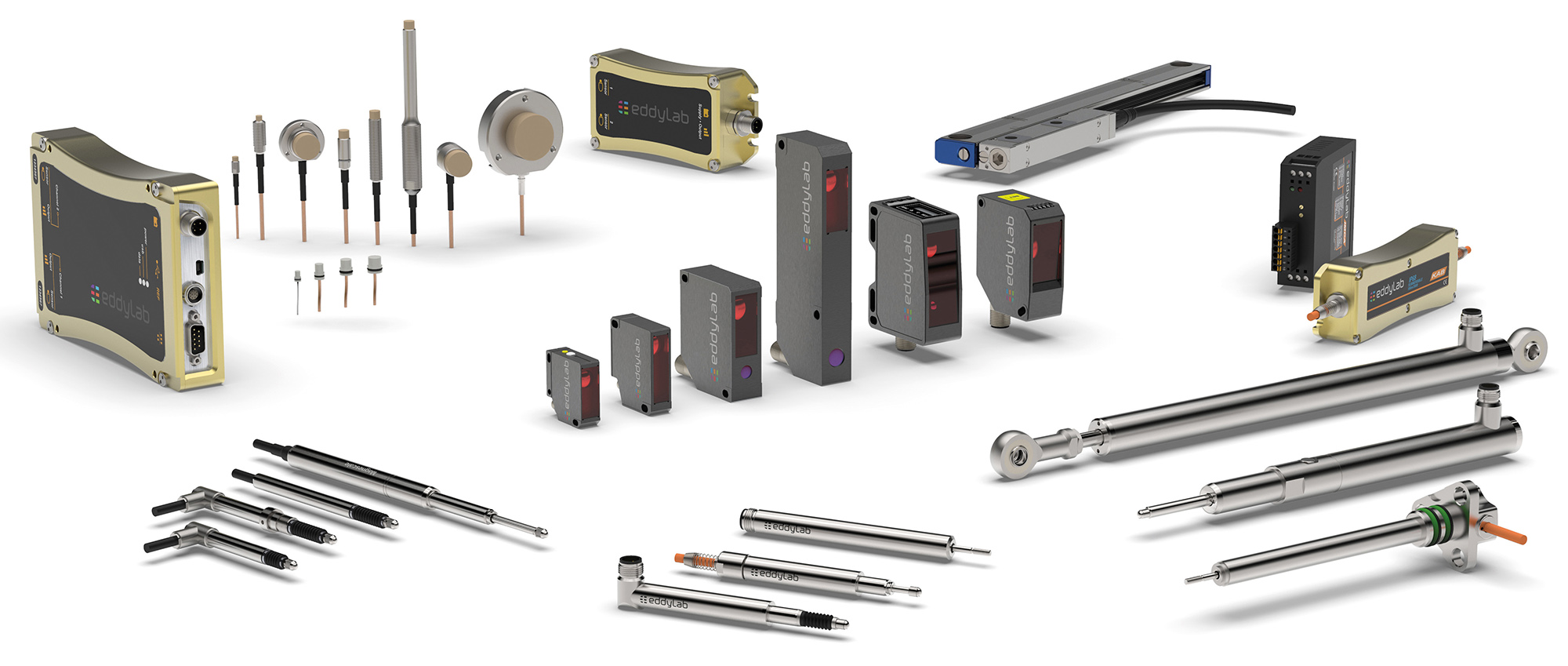

EDDYLAB: eddylab is constantly expanding its range of LVDT/inductive sensors and eddy current sensors. Existing series are continuously optimized, especially regarding protection class and (housing)-materials. New in the eddylab product portfolio are digital laser sensors to measure the distance or the position of an object in a non-contact and wear-free manner – according to the triangulation principle.

E.E: What are the ranges of products?

EDDYLAB: Our focus is on eddy current sensors and inductive sensors, called LVDT. eddylab GmbH is also the official distributor of Magnescale products (formerly Sony Precision Technology) like digital gauges, rulers, and magnetic scales. Laser distance sensors complete our range and are used when a non-contact, optical measuring method is required. In addition, eddylab has a worldwide network of distributors.

E.E: At what stage is the market where you are currently active?

EDDYLAB: We feel that the impact of the Corona crisis on much of our industry has now been offset and that the sensor market in our area is less affected by interrupted supply chains or a decline in orders. eddylab GmbH were even able to increase the sales in 2021 and we assume a further growth in 2022.

E.E: What can you tell us about market trends?

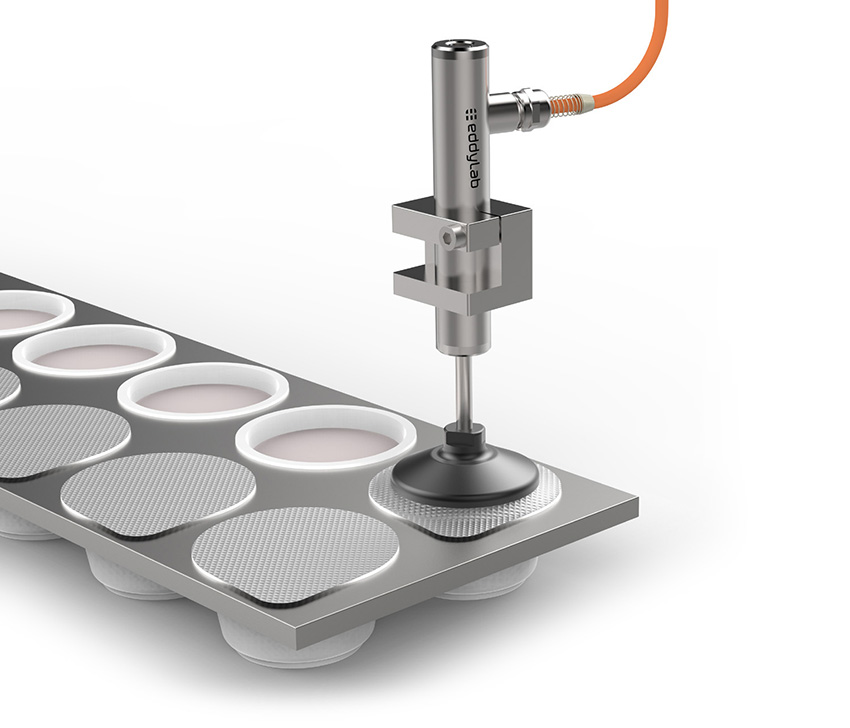

EDDYLAB: Automation continues to be an unbroken trend in our industry. Through all industries like mechanical engineering, electronics manufacturing, automotive, medical, pharmaceutical and food the integration of sensors in control and automation systems has received a great deal of attention. Therefore, our sensors are suitable for wide range of application: As a measuring system on moving machine components or a non-contact position detection of metallic objects, for example. Especially in harsh environmental situations our products are in demand due to their robustness, wear-free operation, and reliability as they are insensitive to high temperature, shock, or pressure.

We always offer our customers the possibility to find individual sensor solutions, i.e., to integrate our sensors into existing applications. Here, adaptations are primarily required regarding mechanics, protection class, temperature range and linearity.

“Retrofit” is also a major trend in the in the field of sensor technology which is becoming more and more important for us. A retrofit is about adapting an old machine to the current technical conditions. With older machines, data or values cannot be recorded in part because there is no specific sensor technology. This is where we come in – by retrofitting machines with sensors for position measurement and control, for example. In the context of Predictive Maintenance, the retrofitting makes it possible to avoid costly failures and downtimes due to unscheduled repairs. eddylab receives an increasing number of requests from customers who are looking for alternatives for their existing sensor systems, due to technical failures or procurement problems caused by discontinuation of a product extreme delivery times. In this case, eddylab GmbH can offer sensors that are specially tailored to the predefined installation situation. The customer in turn benefits from being able to significantly extend the service life of his machines and production systems.

E.E: What are the most innovative products marketed?

EDDYLAB: As specialized company, we have successfully established ourselves in the promising field of energy technology and generation in recent years. The effectiveness of energy generation and storage can only be guaranteed with the help of robust sensor systems, especially in the field of renewable energies. In this field, the focus is on control or monitoring, Predictive Maintenance, and quality assurance, primarily in the development and production of batteries, which plays a key role in the large field of electromobility. In this important future area, both our eddy current sensors and inductive sensors are used by customers in the automotive, wind, energy, and environmental industry.

E.E: What estimations do you have for 2021/2022?

EDDYLAB: The future of the sensor market looks promising. We think that a major driver for this market is the increasing need of automation and process reliability in many industries. For eddylab GmbH, this opens up various opportunities to further expand the adaptation of our sensors into existing processes and applications and to open up new industries.

The increase in the importance of sensors in the automotive and energy sectors means that we must continue on our path of supporting sustainable and efficient energy generation. Especially in this sector, the customer-specific requirements are challenging–but also meet exactly what eddylab GmbH has in focus for2022: The continuous development of our products together with our customers and their increasing demands for customized solutions.